Tool Steel H13/1.2344 Round Steel Bar Alloy Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

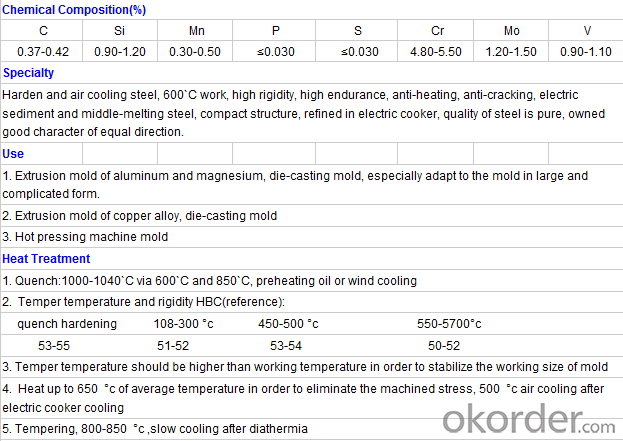

Tool Steel H13/1.2344 Round Steel Bar Alloy Steel Bar

Product information:

H13/1.2344 round bar

1.Diameter:10mm~600mm,

2.Delivery Conditon:annealed, black/turned surface

3.Short Delivery Time

4.Payment:By 30% ,T/T in advanced payment or L/C at sight

5.Min qty:25MT

6.Dlivery terms:CFR or CIF

7.Delivery time:according to your qty

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: What are the different low-temperature grades of special steel?

- Special steel includes several low-temperature grades designed to withstand extreme cold conditions. Among the commonly used grades are the following: 1. Austenitic Stainless Steel: This grade, such as 304 and 316, is renowned for its excellent corrosion resistance and high strength in low temperatures. It finds frequent use in cryogenic applications like LNG storage tanks and cryogenic piping. 2. Ferritic Stainless Steel: Ferritic stainless steel grades, including 410 and 430, possess good ductility and resistance to stress corrosion cracking, making them suitable for low-temperature applications. They are often utilized in cryogenic environments that require both high strength and resistance to embrittlement. 3. Martensitic Stainless Steel: Martensitic stainless steel, such as 410 and 420, delivers high strength and good toughness even in low temperatures. It is commonly employed in applications demanding exceptional wear resistance and strength, such as valves and turbine blades in cryogenic systems. 4. Duplex Stainless Steel: Duplex stainless steel grades like 2205 and 2507 combine high strength, excellent corrosion resistance, and good toughness in low temperatures. They are extensively employed in offshore and subsea applications where low-temperature performance and resistance to pitting and crevice corrosion are crucial. 5. Nickel-Based Alloys: Nickel-based alloys, such as Inconel and Hastelloy, are renowned for their exceptional corrosion resistance and high strength in both low and high temperatures. They are widely used in cryogenic applications, including liquefied natural gas (LNG) processing plants, as well as the aerospace and chemical processing industries. Each of these low-temperature grades of special steel offers distinct properties and advantages, making them suitable for various applications in extreme cold conditions. The appropriate grade selection depends on factors such as the specific temperature range, required corrosion resistance, strength requirements, and environmental conditions.

- Q: What are the main environmental impacts of special steel production?

- The main environmental impacts of special steel production include high energy consumption, significant greenhouse gas emissions, and the generation of large amounts of air and water pollution. The production process requires immense amounts of energy, primarily from fossil fuels, leading to the release of carbon dioxide and other greenhouse gases, contributing to climate change. Additionally, the production of special steel involves the use of various chemicals and the generation of hazardous waste, which can contaminate air and water sources, harming ecosystems and human health. Efforts are being made to mitigate these impacts through improved technologies and practices, such as energy efficiency measures and waste management systems, to minimize the environmental footprint of special steel production.

- Q: What are the requirements for special steel used in robotic applications?

- The requirements for special steel used in robotic applications include high strength and durability, resistance to corrosion and wear, excellent machinability, and the ability to maintain dimensional stability even under high temperatures. Additionally, the steel should have good weldability, be lightweight, and possess high fatigue resistance to ensure reliable and efficient performance in robotic systems.

- Q: Can special steel be used for cutting tools?

- Yes, special steel can be used for cutting tools. Special steels, such as high-speed steel or tool steel, are specifically designed to have superior hardness, toughness, and wear resistance, making them ideal for manufacturing cutting tools that can withstand high temperatures and perform precision cutting operations.

- Q: What are the different heat-resistant grades of special steel?

- There exists a variety of specialized steel grades that possess heat-resistant properties and are specifically engineered to endure elevated temperatures and thermal stress. Some of the commonly utilized heat-resistant grades are as follows: 1. Stainless Steel 310: Renowned for its exceptional resistance against high temperatures, oxidation, and corrosion, stainless steel 310 is capable of withstanding temperatures up to 1100°C (2012°F). It finds extensive application in furnace components, heat treatment baskets, and other heat-intensive scenarios. 2. Inconel 600: Inconel 600 is a nickel-chromium alloy that exhibits remarkable resistance to high temperatures and oxidation. It remains effective within a temperature range spanning from cryogenic levels to 1093°C (2000°F) and is widely employed in gas turbines, heat exchangers, and other environments characterized by elevated temperatures. 3. Hastelloy C-276: Hastelloy C-276, a nickel-molybdenum-chromium alloy, offers outstanding resistance against a broad array of corrosive settings and high temperatures. It can withstand temperatures up to 1093°C (2000°F) and is commonly utilized in chemical processing, power generation, and pollution control applications. 4. Titanium Grade 2: Titanium Grade 2 is a commercially pure titanium alloy that presents favorable resistance to high temperatures and corrosion. It remains effective in temperatures up to 538°C (1000°F) and is frequently employed in heat exchangers, chemical processing equipment, and marine applications. 5. Alloy 617: Alloy 617 is a nickel-chromium-cobalt-molybdenum alloy that showcases exceptional strength and resistance to high-temperature environments. It can endure temperatures up to 1204°C (2200°F) and is commonly utilized in gas turbines, petrochemical plants, and other industries that entail significant heat exposure. These aforementioned examples represent merely a fraction of the heat-resistant grades of specialized steel accessible in the market. The appropriate grade selection relies on the specific temperature requirements, corrosion resistance, and mechanical properties demanded by the application at hand.

- Q: What are the main applications of special steel in the food packaging industry?

- Special steel is widely used in the food packaging industry due to its various applications. It is primarily utilized in the production of food cans, closures, and other packaging materials. Special steel offers excellent corrosion resistance, ensuring the preservation and safety of the packaged food. It also provides high strength and durability, maintaining the integrity of the packaging during transportation and storage. Additionally, special steel can be easily formed into different shapes and sizes, allowing for versatile packaging designs. Overall, the main applications of special steel in the food packaging industry include ensuring food safety, promoting product longevity, and enabling creative packaging solutions.

- Q: Can special steel be used in high-pressure applications?

- Yes, special steel can indeed be used in high-pressure applications. Special steels, also known as alloy steels, are specifically designed to have enhanced mechanical properties such as high strength, ductility, and corrosion resistance. These properties make them suitable for withstanding high-pressure environments. Special steels are commonly used in industries such as oil and gas, aerospace, automotive, and power generation, where high-pressure applications are encountered. For example, in the oil and gas industry, special steels are used to manufacture high-pressure pipelines, valves, and pressure vessels that can withstand the extreme pressure conditions during oil drilling, transportation, and refining processes. The high strength of special steel allows it to withstand the internal pressure exerted by fluids or gases without deformation or failure. Additionally, its corrosion resistance properties ensure that the steel remains intact and free from damage caused by the harsh operating conditions often associated with high-pressure applications. Moreover, special steels can be tailored to meet specific requirements by adjusting their chemical composition and heat treatment processes. This customization allows the steel to exhibit even higher strength, toughness, and resistance to fatigue, making it ideal for applications involving high-pressure environments. In summary, special steel can be used in high-pressure applications due to its enhanced mechanical properties and corrosion resistance. Its ability to withstand extreme pressures makes it a reliable choice for various industries where high-pressure conditions are encountered.

- Q: How does special steel compare to stainless steel?

- Special steel and stainless steel are two distinct types of steel with different properties and applications. While stainless steel is known for its corrosion resistance, special steel is recognized for its exceptional strength and durability. Special steel is often used in high-stress environments where resistance to wear, impact, or extreme temperatures is crucial. On the other hand, stainless steel is preferred in applications where resistance to rust and staining is essential, such as in kitchen appliances or medical instruments. Therefore, the choice between special steel and stainless steel depends on the specific requirements and desired characteristics for a particular application.

- Q: What are the mechanical properties of special steel?

- Special steel generally refers to high-performance alloys that have enhanced mechanical properties compared to conventional steels. These properties can vary depending on the specific composition and heat treatment of the special steel. However, some common mechanical properties of special steel include high strength, excellent toughness, improved wear resistance, and good corrosion resistance. Special steel is often used in applications requiring exceptional performance, such as in aerospace, automotive, and tooling industries.

- Q: How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel is known for its exceptional wear resistance in abrasive environments. The unique composition and heat treatment processes used in the production of special steel result in a higher hardness level compared to standard steels. This increased hardness makes special steel highly resistant to wear caused by abrasive particles or surfaces. In abrasive environments where friction and contact with hard materials are prevalent, special steel exhibits excellent performance. It can withstand the erosive effects of abrasive particles, such as sand, rocks, or metal fragments, without significant wear or damage. This durability makes special steel an ideal choice for various applications, including mining equipment, cutting tools, industrial machinery, and automotive components. Moreover, the wear resistance of special steel is not only limited to its surface but also extends throughout its structure. This means that even if the surface of the steel is scratched or abraded, the underlying material remains highly resistant to wear. This characteristic ensures a prolonged lifespan of components made from special steel, reducing maintenance costs and downtime. Furthermore, special steel can maintain its wear resistance even under high temperatures. This property is particularly advantageous in abrasive environments where friction-induced heat can accelerate wear. The ability of special steel to retain its hardness and wear resistance at elevated temperatures ensures its effectiveness in demanding applications like high-speed machining or hot forging. Overall, special steel outperforms standard steels in terms of wear resistance in abrasive environments. Its superior hardness, structural integrity, and temperature resistance make it an excellent choice for applications where durability and longevity are essential.

Send your message to us

Tool Steel H13/1.2344 Round Steel Bar Alloy Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords