Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

| Material | 40Mn 50Mn 20CrNi4 | Round bar | Dia(mm) | 16-600 |

| Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

| Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500 |

| Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200 | |

| Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12000 | |

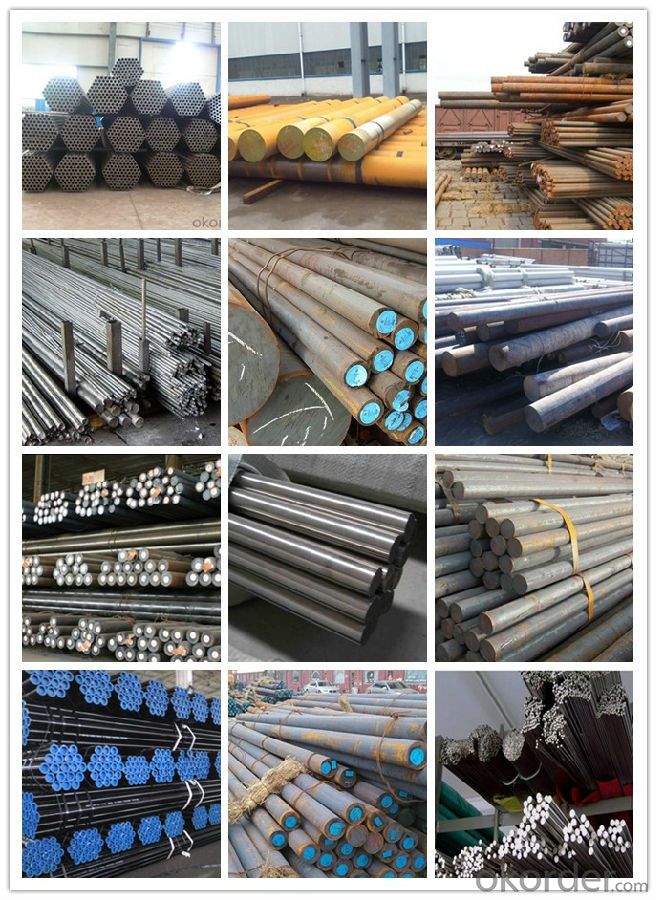

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q: How does heat treatment affect the properties of special steel?

- Heat treatment can significantly impact the properties of special steel. The process involves heating and cooling the steel in a controlled manner, which alters its microstructure, resulting in changes to its hardness, strength, toughness, and ductility. By carefully selecting the temperature and duration of heat treatment, desired properties such as improved hardness, increased strength, and enhanced wear resistance can be achieved. Additionally, heat treatment can also relieve internal stresses, enhance machinability, and improve dimensional stability of special steel.

- Q: How does special steel contribute to the durability of products?

- Special steel contributes to the durability of products in several ways. Firstly, special steel is known for its high strength and hardness, making it resistant to wear and tear. This ensures that products made from special steel can withstand heavy use and last longer than those made from regular steel or other materials. Additionally, special steel is often alloyed with other elements such as chromium, nickel, and molybdenum, which enhances its corrosion resistance. This is particularly important for products that are exposed to harsh environments or chemicals. The corrosion resistance of special steel helps prevent rust and degradation, increasing the lifespan of the product. Furthermore, special steel can be heat-treated to improve its mechanical properties, such as toughness and hardness. Heat-treated special steel undergoes specific heating and cooling processes to enhance its strength, making it less prone to deformation and breakage. This is particularly beneficial for products that are subject to heavy loads or impacts. Moreover, special steel is often manufactured with precise composition and microstructure, which results in improved material properties. This includes better fatigue resistance, meaning the material can withstand repeated stress without cracking or breaking. Products made from special steel are therefore more reliable and less prone to failure. In summary, special steel contributes to the durability of products through its high strength, corrosion resistance, improved mechanical properties, and better fatigue resistance. By utilizing special steel in the manufacturing process, products can be designed to withstand various demanding conditions, ensuring a longer lifespan and greater reliability.

- Q: Can special steel be used for making springs?

- Indeed, springs can be crafted using special steel. Recognized as alloy steel, special steel possesses augmented mechanical attributes like impressive tensile strength, toughness, and resistance against corrosion. Consequently, it serves as an optimal substance for the production of robust and dependable springs across diverse applications. The precise variant of special steel employed in spring production hinges upon the particular necessities of the application, be it a desired degree of flexibility or resistance against fatigue. All in all, special steel bestows extraordinary performance and endurance in the realm of spring manufacturing.

- Q: What are the main applications of special steel in the chemical processing industry?

- Special steel has various applications in the chemical processing industry, primarily due to its excellent corrosion resistance, high temperature resistance, and strength. It is commonly used in the construction of chemical storage tanks, pipes, and reactors, where it helps to prevent leaks and maintain the integrity of the process. Additionally, special steel is utilized in the manufacturing of valves, pumps, and heat exchangers, ensuring reliable and efficient operations in chemical plants.

- Q: How does special steel perform in high-pressure hydrogen environments?

- Special steel performs well in high-pressure hydrogen environments due to its high strength, corrosion resistance, and ability to withstand hydrogen embrittlement. It offers reliable performance and minimizes the risk of hydrogen-induced failures, making it a suitable choice for applications such as hydrogen storage, transportation, and fuel cells.

- Q: How does special steel contribute to the manufacturing industry?

- Special steel contributes to the manufacturing industry by providing a high-quality and versatile material that can be used in various applications. Its unique properties, such as increased strength, durability, and resistance to corrosion, make it suitable for manufacturing components and machinery used in sectors like automotive, aerospace, construction, and energy. Special steel enhances product performance, extends equipment lifespan, and enables the development of innovative solutions, ultimately driving productivity and competitiveness in the manufacturing industry.

- Q: How does special steel perform in high-temperature corrosion resistance?

- Special steel is renowned for its outstanding performance in resisting corrosion at high temperatures. It is specifically crafted to endure harsh circumstances and maintain its integrity even when exposed to elevated temperatures. The composition of special steel incorporates various alloying elements, including chromium, nickel, molybdenum, and others, which enhance its resistance to corrosion in high-temperature settings. When subjected to high temperatures, numerous materials have a tendency to oxidize or react with the surrounding environment, resulting in corrosion and deterioration. However, special steel develops a protective oxide layer on its surface, serving as a barrier against corrosive elements. This oxide layer, primarily composed of chromium, remains stable and possesses self-repairing properties, effectively preventing further corrosion and upholding the structural integrity of the steel. Moreover, the incorporation of alloying elements like molybdenum enhances the steel's ability to resist pitting and crevice corrosion, which are commonly observed in high-temperature environments. Special steel also exhibits exceptional mechanical properties even at elevated temperatures, ensuring structural stability and preventing deformation or failure under stress. Additionally, special steel is frequently subjected to heat treatment to bolster its resistance to corrosion at high temperatures. Heat treatment processes such as annealing, tempering, or quenching and tempering optimize the steel's microstructure and mechanical properties, rendering it more impervious to corrosion in extreme conditions. In conclusion, special steel excels in its ability to resist corrosion at high temperatures due to its distinct composition, protective oxide layer, and heat treatment procedures. It is a dependable and long-lasting material choice for applications that involve exposure to elevated temperatures and corrosive environments, such as in chemical processing plants, power generation facilities, or oil and gas refineries.

- Q: How does special steel contribute to the manufacturing of cutting blades?

- Special steel plays a crucial role in the manufacturing of cutting blades. Cutting blades are required to have exceptional strength, durability, and sharpness to efficiently perform their function. Special steel, also known as tool steel, possesses unique properties that make it an ideal material for manufacturing cutting blades. Firstly, special steel has excellent hardness, which enables cutting blades to maintain their sharpness for an extended period. Cutting blades made from special steel can withstand the wear and tear that occurs during cutting operations. This hardness allows the blades to retain their cutting edge, resulting in a longer lifespan and improved cutting performance. Moreover, special steel offers exceptional toughness, which is crucial for cutting blades. During cutting operations, blades are subjected to high impact and stress. Special steel's toughness helps absorb these forces and prevents the blades from breaking or chipping. This ensures that the cutting blades can withstand demanding cutting tasks without compromising their performance. Additionally, special steel provides excellent corrosion resistance. Cutting blades often come into contact with various materials, including moisture and chemicals. The corrosion resistance of special steel prevents the blades from rusting or corroding, ensuring their longevity and reducing the need for frequent replacements. Furthermore, special steel offers good machinability, making it easier to shape and form into the desired blade design. This enhances the manufacturing process by enabling the production of cutting blades with complex shapes and intricate features. The machinability of special steel allows manufacturers to create blades with precise cutting edges and optimal geometries, resulting in superior cutting performance. In conclusion, special steel contributes significantly to the manufacturing of cutting blades by providing hardness, toughness, corrosion resistance, and good machinability. These properties ensure that cutting blades made from special steel are long-lasting, durable, and capable of delivering exceptional cutting performance in various applications.

- Q: How does special steel contribute to reducing product defects during manufacturing?

- Special steel contributes to reducing product defects during manufacturing by offering superior strength, durability, and resistance to corrosion. It ensures the production of high-quality components that are less prone to wear, deformation, or breakage, minimizing the occurrence of defects. Additionally, special steel's consistent composition and precise manufacturing processes enable tighter tolerances, resulting in more accurate and reliable products.

- Q: How does special steel play a role in the defense sector?

- Special steel plays a crucial role in the defense sector due to its exceptional strength, durability, and resistance to heat, corrosion, and impact. It is used to manufacture various defense equipment and vehicles, including tanks, submarines, aircraft carriers, and ballistic missile systems. Special steel ensures the structural integrity and performance of these defense assets, providing enhanced protection, firepower, and overall operational efficiency in critical military operations.

Send your message to us

Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords