HSS Steel Round Bar Alloy Round Tool Steel Bar/M2/M25M42/D2/H13

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 556 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel round bar:

Characteristic:Tungsten-molybdenum high speed steel developed by China,high performance in toughness ,hardness, high temperature hardness.

Festures of steel round bar:

Anneal temperature: 840-860

Relief annealing temperature: 720-760

Hardening temperature: 1210-1230

Hardening medium: salt bath under 600,aslo use oil cooling or air cooling

Normal temper temperation: 540-560 RC Rockwell Hardness after hardening and temperature: 63-66

Production Capacity: 1000 Tons/Month

Tech:EAF+LF+VD+ESR

High strength at elevated temperatures

Specifications of steel round bar:

| C | Si | Mn | W | Mo | Cr | V | P | S |

| 0.80-0.90 | 0.20-0.45 | 0.15-0.40 | 5.50-6.75 | 4.50-5.50 | 3.80-4.40 | 1.75-2.20 | ≤0.030 | ≤0.030 |

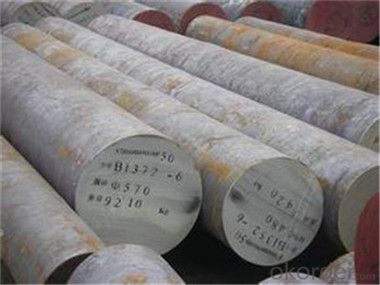

Images of steel round bar:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel round bars be used in the manufacturing of marine propellers?

- Yes, steel round bars can be used in the manufacturing of marine propellers. Steel is a commonly used material for propellers due to its high strength, durability, and resistance to corrosion in marine environments. By using steel round bars, manufacturers can easily shape and form the propeller blades, ensuring optimal performance and longevity in marine applications.

- Q: What are the advantages of using carbon steel round bars?

- Using carbon steel round bars in various applications offers several advantages. To begin with, carbon steel round bars are renowned for their exceptional strength and durability. They possess a high tensile strength, making them ideal for heavy-duty tasks that involve carrying substantial loads and enduring intense pressures. As a result, carbon steel round bars find extensive use in the construction, manufacturing, and engineering sectors. Another benefit of carbon steel round bars lies in their remarkable machinability. They can be effortlessly cut, drilled, and shaped into diverse forms, rendering them highly versatile for different projects. This flexibility allows for precise and accurate fabrication, ensuring that the desired specifications and dimensions are achieved. Furthermore, carbon steel round bars exhibit excellent weldability, enabling easy joining using various welding techniques. This feature makes them highly preferred for constructing structures and machinery that demand strong and secure connections. Moreover, carbon steel round bars offer a cost-effective solution compared to other materials with similar properties. They strike an optimal balance between performance and affordability, making them a favored choice across many applications. Additionally, their long lifespan and minimal maintenance requirements contribute to cost savings over time. Carbon steel round bars also possess a high resistance to corrosion and wear, thanks to the presence of carbon and other alloying elements. This enhanced resistance shields them from external factors like moisture, chemicals, and abrasion. Consequently, carbon steel round bars can endure harsh environments and prolonged exposure to various elements, making them well-suited for outdoor applications. Lastly, the widespread use and popularity of carbon steel round bars ensure their ready availability in the market. They can be found in various sizes, grades, and specifications, allowing users to select the most suitable option for their specific needs. This availability streamlines the sourcing process and reduces lead times for projects. In conclusion, the utilization of carbon steel round bars provides numerous advantages, including exceptional strength, excellent machinability, good weldability, affordability, corrosion resistance, and availability. These qualities establish carbon steel round bars as a reliable and versatile choice for a wide range of applications across different industries.

- Q: Can steel round bars be used in the production of HVAC equipment?

- Certainly, HVAC equipment production can indeed make use of steel round bars. In the manufacturing of diverse HVAC components such as air ducts, frames, supports, brackets, and other structural elements, steel round bars find extensive application. Steel is widely preferred in HVAC equipment owing to its exceptional strength, durability, and resistance to corrosion. Its high tensile strength ensures its suitability in handling the mechanical stresses and loads encountered by HVAC systems. Furthermore, steel can endure high temperatures and is non-combustible, rendering it a secure material for HVAC purposes. On the whole, the reliability, longevity, and performance of steel round bars make them extensively employed in HVAC equipment production.

- Q: What are the different types of steel round bar surface finishes?

- Steel round bars can be treated with various surface finishes to meet different needs. Some of the most commonly used finishes are: 1. Bright: By polishing the steel round bar, a shiny and reflective surface is achieved. This finish is often employed for decorative purposes or when aesthetics are important. 2. Grinded: To achieve a smooth and even surface, the outer layer of the steel round bar is removed using a grinding wheel or abrasive belt. This finish is useful for eliminating imperfections or creating a uniform surface for further processing. 3. Brushed: Fine lines are created on the surface of the steel round bar using a wire brush or abrasive pad. This finish is preferred for its unique aesthetic appeal and is commonly used in architectural applications. 4. Powder-coated: Dry powder is applied to the surface of the steel round bar and then cured using heat. This finish provides a durable and corrosion-resistant coating that can be applied in various colors and textures. 5. Galvanized: A protective zinc coating is applied to the steel round bar to prevent corrosion. This finish is commonly used in outdoor or marine applications where the steel is exposed to moisture or harsh environmental conditions. 6. Oiled: A thin layer of oil is applied to the surface of the steel round bar. This finish offers temporary protection against corrosion and is often used for short-term storage or transportation purposes. 7. Shot-blasted: Small metallic or non-metallic particles are propelled at high speeds onto the surface of the steel round bar. This process creates a textured finish that improves the adhesion of subsequent coatings or paints. Each type of surface finish has its own unique advantages and is selected based on the specific requirements of the application.

- Q: What is the maximum silicon content allowed for steel round bars?

- The maximum silicon content allowed for steel round bars can vary depending on the specific grade and application of the steel. However, in general, the maximum silicon content for most standard carbon and alloy steels used in round bars is typically around 0.35% to 0.45%. Exceeding this limit can lead to detrimental effects on the steel's mechanical properties, such as reduced toughness and increased brittleness. It is important to consult the relevant industry standards and specifications to determine the specific maximum silicon content allowed for a particular steel grade and intended use.

- Q: What are the different types of steel round bars available in the market?

- There are several different types of steel round bars available in the market, each with its own unique characteristics and applications. Some of the most common types include: 1. Mild Steel Round Bars: These are the most commonly used type of steel round bars due to their versatility and affordability. They have a low carbon content and are easy to weld and machine, making them suitable for a wide range of applications. 2. Carbon Steel Round Bars: Carbon steel round bars have a higher carbon content than mild steel, which gives them increased strength and hardness. They are commonly used in applications that require high strength, such as construction and machinery manufacturing. 3. Alloy Steel Round Bars: Alloy steel round bars are made by adding various alloying elements, such as chromium, nickel, or molybdenum, to improve their mechanical properties. These bars offer enhanced strength, toughness, and resistance to wear and corrosion, making them ideal for applications in the aerospace, automotive, and oil and gas industries. 4. Stainless Steel Round Bars: Stainless steel round bars are highly corrosion-resistant due to the presence of chromium, which forms a protective oxide layer on the surface. They are widely used in industries such as food processing, pharmaceuticals, and chemical processing, where resistance to corrosion and hygiene are crucial. 5. Tool Steel Round Bars: Tool steel round bars are specifically designed for tooling applications, such as cutting, drilling, and shaping materials. They have high hardness, wear resistance, and heat resistance, making them suitable for manufacturing tools and dies. 6. Duplex Steel Round Bars: Duplex steel round bars are a type of stainless steel that contains both austenitic and ferritic microstructures. They offer a combination of high strength, excellent corrosion resistance, and good weldability, making them ideal for applications in the chemical and petrochemical industries. These are just a few examples of the different types of steel round bars available in the market. The choice of the right type depends on the specific requirements of the application, including strength, corrosion resistance, machinability, and cost.

- Q: What is the impact strength of a steel round bar?

- The ability of a steel round bar to withstand sudden forces or shocks without breaking or fracturing is referred to as its impact strength. This characteristic is a measure of the material's toughness and its ability to resist impact loads. Various factors, including the steel's composition, heat treatment, and any additional alloying elements, influence the impact strength of a steel round bar. To determine the impact strength, testing methods such as the Charpy or Izod impact test are typically employed. These tests involve striking a notched sample of the steel bar with a pendulum and measuring the amount of energy absorbed by the material before it fractures. The results are usually reported in terms of the energy absorbed in joules (J) or foot-pounds (ft-lb). The impact strength of a steel round bar can vary significantly depending on its grade or specification. Different grades of steel possess varying levels of toughness, making some more suitable for applications requiring high impact resistance, such as construction, automotive, or heavy machinery. On the other hand, certain grades may be better suited for less demanding applications. It should be noted that the impact strength is just one of several mechanical properties that must be considered when selecting a steel round bar for a specific application. Other factors, such as tensile strength, yield strength, hardness, and corrosion resistance, should also be taken into account to ensure the optimal performance and durability of the steel round bar in its intended use.

- Q: Are steel round bars corrosion-resistant?

- The corrosion resistance of steel round bars varies depending on the specific steel type and the conditions they are exposed to. Stainless steel round bars, for instance, possess exceptional corrosion resistance due to the inclusion of chromium and other alloying elements. These elements facilitate the formation of a protective oxide layer on the steel's surface, which effectively prevents corrosion and rusting. However, not all steel round bars possess inherent corrosion resistance. Carbon steel round bars, for instance, are more susceptible to corrosion and necessitate protective coatings or treatments to enhance their resistance. Therefore, it is crucial to consider the precise grade and composition of steel round bars to determine their corrosion resistance properties.

- Q: Is round bar steel?

- Round steel is the term of steel structure, and the requirement of material is different from that of concrete structure.

- Q: What is the difference between strip steel and round steel? Where are they mainly used?

- Difference between round bar and other steel bars:(1), is not the same, round shape light round, no pattern without ribs, other steel surface appearance is engraved or ribbed, cohesive force that cause steel and concrete, and the bond strength of steel and concrete in the other.(2) the composition is different. Round steel (grade a steel) belongs to ordinary low carbon steel, and most other steel bars are alloy steel.(3), the strength is not the same, low strength steel, and other steel with high strength, the diameter of the same size as compared with other steel, round steel can bear the pulling force than other reinforced small, but the plastic steel reinforced bar is stronger than the other, there is a large deformation in the break before, while the other bars in the break before the deformation is much smaller.

Send your message to us

HSS Steel Round Bar Alloy Round Tool Steel Bar/M2/M25M42/D2/H13

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 556 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords