Tool Steel Bar 5140 Alloy Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tool Steel Bar 5140 Alloy Steel Round Bar

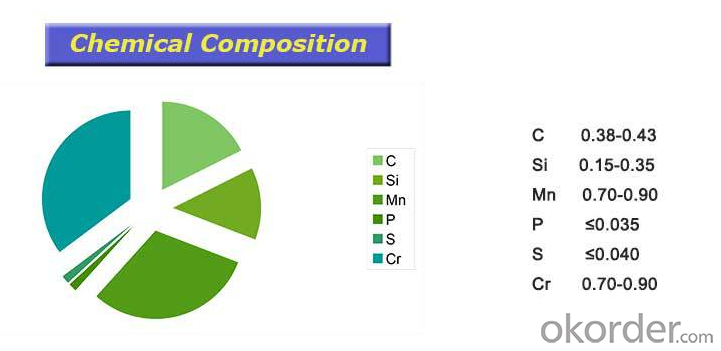

Product information:

| Tensile Strength (N/mm2Mpa) | ≥980 |

| Elongation ( % ) | ≥9 |

| Yield strength | ≥785 |

| Hardness( HBS ) | ≤20 |

| Reduction of area | ≥45% |

Other product show:

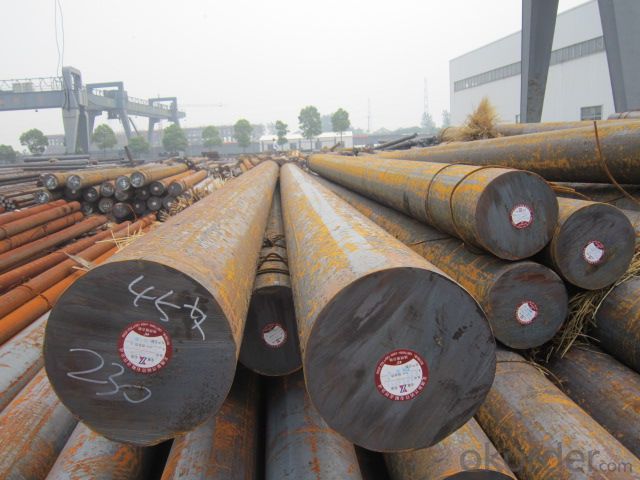

Our workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: What are the applications of special steel in the food processing industry?

- Special steel is widely used in the food processing industry due to its unique properties. It is utilized for manufacturing various equipment and components that require high strength, corrosion resistance, and hygiene standards. Some applications include the production of food processing machinery, cutting tools, knives, blades, and containers. Special steel ensures durability, cleanliness, and safety, making it an indispensable material in the food processing industry.

- Q: What are the different methods of surface finishing for special steel?

- There are several different methods of surface finishing for special steel, each offering unique benefits and achieving specific aesthetic or functional requirements. Some of the most commonly used methods include: 1. Electroplating: This process involves depositing a layer of metal onto the special steel surface through an electrochemical reaction. It provides enhanced corrosion resistance, improved appearance, and can also offer increased hardness or wear resistance. 2. Passivation: Passivation is a chemical treatment that removes surface contaminants and forms a thin oxide layer on the special steel. This process enhances corrosion resistance by preventing the formation of rust or other oxidation products. 3. Polishing: Polishing is a mechanical process that involves using abrasive materials to remove a thin layer of the steel surface, resulting in a smooth and shiny finish. This method is often used to improve the appearance of special steel products or to achieve a specific level of reflectivity. 4. Shot blasting: Shot blasting is a technique that involves propelling small metal beads or shots at high speed onto the special steel surface. This process removes scale, rust, or other surface contaminants, resulting in a clean and textured finish. Shot blasting is commonly used to prepare the steel for subsequent coating or painting applications. 5. Physical vapor deposition (PVD): PVD is a vacuum-based coating process that involves depositing a thin layer of material onto the special steel surface. This method offers excellent adhesion, wear resistance, and can provide various colors or finishes to enhance the aesthetics of the steel. 6. Powder coating: Powder coating involves applying a dry powder onto the special steel surface, which is then cured under heat to form a protective and decorative layer. This method offers excellent corrosion resistance, durability, and a wide range of color options. 7. Anodizing: Anodizing is an electrolytic process that creates a controlled oxide layer on the surface of certain special steel alloys. It provides increased corrosion resistance, improved appearance, and can also enhance hardness or wear resistance. These are just a few of the many methods available for surface finishing special steel. The choice of method will depend on factors such as the desired finish, functional requirements, and the specific properties of the steel being used.

- Q: How does special steel contribute to improving product efficiency?

- Special steel contributes to improving product efficiency in several ways. Firstly, special steel typically has superior strength, durability, and corrosion resistance compared to regular steel. This allows manufacturers to design and produce products that can withstand higher loads, operate under harsh conditions, and have a longer lifespan. Secondly, special steel often has specific properties such as heat resistance or magnetic properties, which can be utilized in various industries like aerospace, automotive, and electronics. These properties enable the creation of more efficient and advanced products, such as high-performance engines, lightweight structures, or specialized electrical components. Additionally, special steel can be tailored to specific manufacturing processes, resulting in improved precision and productivity. Overall, the use of special steel enables the development of higher-quality, more reliable, and efficient products across multiple industries.

- Q: Are there any international standards for special steel?

- Yes, there are international standards for special steel. The most widely recognized and accepted international standards for special steel are set by the International Organization for Standardization (ISO). ISO develops and publishes a range of standards that cover various aspects of special steel, including composition, properties, testing methods, and quality requirements. These standards ensure that special steel produced by different manufacturers from different countries meet the same minimum quality and performance criteria. In addition to ISO, there are also other organizations and standards bodies that have their own specific standards for special steel, such as the American Society for Testing and Materials (ASTM) and the European Committee for Iron and Steel Standardization (ECISS). These international standards provide a common framework for the production, trade, and use of special steel across different countries and industries, promoting consistency, reliability, and quality assurance.

- Q: How does special steel contribute to the corrosion resistance of products?

- Special steel contributes to the corrosion resistance of products by incorporating specific alloying elements that enhance its ability to withstand the effects of corrosion. These alloying elements, such as chromium and nickel, form a protective layer on the surface of the steel, known as a passive film. This passive film acts as a barrier, preventing oxygen and moisture from reaching the underlying metal, thus reducing the likelihood of corrosion. The high levels of chromium in special steel, for example, enable the formation of a dense and stable chromium oxide layer on the surface. This layer acts as a physical barrier, preventing the diffusion of corrosive agents and inhibiting the formation of rust. Additionally, the presence of nickel in the alloy further enhances the corrosion resistance of the steel by promoting the formation of a more uniform and adherent passive film. Moreover, special steel can be specially treated or processed to enhance its corrosion resistance. Techniques such as heat treatment and surface coating can modify the structure and composition of the steel, promoting the formation of more stable passive films and reducing the susceptibility to corrosion. These treatments also help to improve the mechanical properties of the steel, making it more durable and resistant to external factors that may lead to corrosion. In summary, the use of special steel in various products contributes to their corrosion resistance by incorporating alloying elements and employing specific treatments that promote the formation of protective passive films. This, in turn, prolongs the lifespan of the products and ensures their performance and integrity, even in harsh and corrosive environments.

- Q: Does special steel have any magnetic properties?

- Depending on its composition and treatment, special steel can indeed possess magnetic properties. The primary constituent of steel is iron, which is inherently ferromagnetic and capable of being magnetized. However, the magnetic characteristics of steel can be influenced by the presence of other elements such as nickel, cobalt, and various alloys. For example, stainless steel, which contains chromium and nickel, is typically either non-magnetic or only weakly magnetic. Conversely, materials like tool steel or high-speed steel may exhibit more pronounced magnetic properties due to their specific composition and heat treatment. Consequently, it is crucial to take into account the precise type of special steel and its alloying elements when assessing its magnetic behavior.

- Q: How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel is renowned for its remarkable ability to resist wear in environments with abrasives. The unique combination of elements and the specific heat treatment methods employed during its production result in a greater level of hardness compared to regular steels. This enhanced hardness grants special steel exceptional resistance to wear caused by abrasive particles or surfaces. In environments where friction and contact with hard materials are prevalent, special steel demonstrates outstanding performance. It can endure the erosive effects of abrasive particles, such as sand, rocks, or metal fragments, without experiencing significant wear or damage. This durability positions special steel as the ideal choice for various applications, including mining equipment, cutting tools, industrial machinery, and automotive components. Furthermore, the wear resistance of special steel extends beyond its surface, permeating throughout its structure. Consequently, even if the steel's surface becomes scratched or abraded, the underlying material remains highly resistant to wear. This characteristic ensures that components made from special steel enjoy an extended lifespan, thereby reducing maintenance costs and downtime. Moreover, special steel retains its wear resistance even when subjected to high temperatures. This property proves particularly advantageous in abrasive environments where the heat generated by friction can accelerate wear. The ability of special steel to maintain its hardness and wear resistance at elevated temperatures guarantees its effectiveness in demanding applications such as high-speed machining or hot forging. Overall, special steel surpasses standard steels when it comes to wear resistance in abrasive environments. Its superior hardness, structural integrity, and temperature resistance make it an excellent choice for applications where durability and longevity are crucial.

- Q: How is special steel used in the manufacturing of industrial machinery?

- Special steel is used in the manufacturing of industrial machinery due to its exceptional strength, durability, and resistance to high temperatures and corrosion. It is commonly employed to create components such as gears, shafts, bearings, and tools, ensuring optimal performance and longevity of the machinery in demanding industrial environments.

- Q: What are the different methods for joining special steel?

- Special steel, commonly used in applications requiring high strength, corrosion resistance, or specific mechanical properties, can be joined using various methods. Some of the most frequently employed methods include: 1. Welding: The most commonly used technique for joining special steel is welding. Different welding methods can be utilized, such as arc welding (including shielded metal arc welding, gas metal arc welding, and flux-cored arc welding), resistance welding (spot welding, seam welding), and laser welding. Welding necessitates the use of filler material to bond the steel components together, resulting in strong and durable joints. 2. Brazing: The process of joining special steel through brazing involves the use of a filler material (typically a brass or bronze alloy) with a lower melting point than the base steel. The filler material is heated until it melts and flows into the joint, creating a robust bond. Brazing is commonly employed for joining dissimilar metals or when the base steel possesses a high melting point. 3. Soldering: Similar to brazing, soldering involves the use of a filler material with a lower melting point to join special steel. However, soldering usually employs a non-ferrous filler material, such as tin-lead or tin-silver alloys. Soldering is frequently utilized for joining electronic components or fragile parts that cannot endure high temperatures. 4. Mechanical Fastening: Special steel can also be joined using mechanical fasteners, including bolts, screws, rivets, or clips. This method is often chosen when the joint needs to be easily disassembled or when welding or brazing is impractical or undesirable. 5. Adhesive Bonding: Adhesive bonding involves the use of specialized adhesive or glue to join special steel. This method is suitable when joining thin or delicate steel components or when the joint requires high resistance to vibration or shock. Adhesive bonding can create a strong and durable bond, although it may not be suitable for high-temperature or high-stress applications. When selecting the appropriate method for joining special steel, it is crucial to consider the specific requirements of the application, such as strength, corrosion resistance, temperature resistance, and desired permanence of the joint. Each method possesses its own advantages and limitations, and choosing the right approach ensures a robust and dependable joint.

- Q: How is high-strength steel used in the automotive industry?

- High-strength steel is widely used in the automotive industry for its ability to enhance the safety and performance of vehicles. It is used in various components such as the frame, chassis, and body structure to improve structural integrity, reduce weight, and provide better crash protection. Additionally, high-strength steel allows automakers to design vehicles with improved fuel efficiency and increased load-carrying capacity, making it a crucial material in modern automotive manufacturing.

Send your message to us

Tool Steel Bar 5140 Alloy Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords