Hot-dip Zinc Coating Steel Building Roof Walls With Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls With Best Price

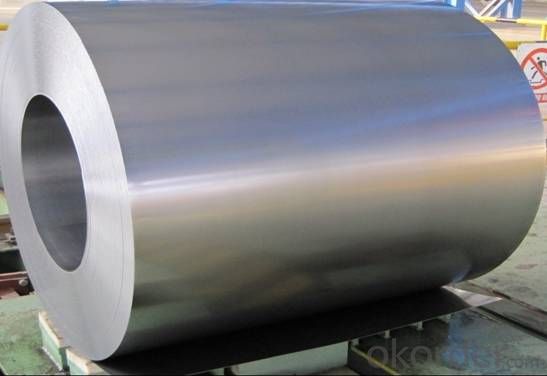

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

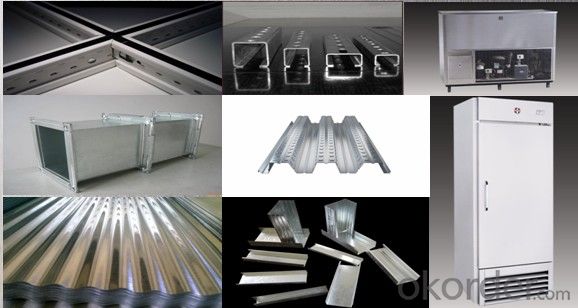

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- All stainless steel is non magnetic.

- Q: What are the common methods of storing steel coils in warehouses?

- Warehouses employ various methods to store steel coils, taking into account factors such as coil size and weight, available space, and resources. Here are some commonly utilized techniques: 1. Block stacking: Coils are stacked directly on top of one another in a block formation. Typically, they are arranged in rows and columns, with wooden or rubber blocks inserted between layers to maintain stability and prevent damage. 2. Racking systems: Racks are frequently employed to store steel coils efficiently. These systems encompass different types of racks, such as cantilever racks, coil racks, and structural racks. They provide an organized framework for storing and accessing coils, maximizing space utilization. 3. Coil cradles: Designed specifically for steel coils, coil cradles consist of multiple cradles or saddles that securely hold the coils in place. By stacking these cradles, warehouses can optimize vertical space usage. 4. Coil pads: Coil pads are flat platforms made of materials like wood, rubber, or foam. They are placed on the warehouse floor, serving as a base for directly stacking steel coils. Coil pads distribute the weight evenly while protecting the coils from floor contact damage. 5. Slit coil storage: Specialized storage systems are employed for storing narrower and lighter slit coils. These systems often include racks or shelves equipped with dividers or separators to maintain coil organization and prevent unraveling. It is crucial to observe safety precautions when handling and storing steel coils in warehouses, regardless of the storage method. This entails ensuring proper weight distribution, utilizing appropriate lifting equipment, and adhering to industry-specific guidelines and regulations.

- Q: How do steel coils contribute to the transportation industry?

- Steel coils play a significant role in the transportation industry due to their versatility and durability. These coiled steel sheets are used for various purposes, such as manufacturing automobiles, shipping containers, and railway cars. In the automotive industry, steel coils are used to produce various components, such as body panels, chassis, and engine parts. The strength and malleability of steel make it an ideal material for ensuring the safety and durability of vehicles. Additionally, steel coils are used in the manufacturing of shipping containers that are used to transport goods across the globe. The sturdiness and resistance to corrosion provided by steel coils ensure the protection of goods during transportation. Furthermore, steel coils are crucial in the railway industry. They are used to manufacture railway cars, including freight cars and passenger coaches. The strength and durability of steel make it ideal for withstanding the heavy loads and harsh operating conditions experienced by railway vehicles. Steel coils also contribute to the construction of railroad tracks and bridges, providing the necessary strength and stability for safe and efficient transportation. Overall, steel coils are essential in the transportation industry as they provide the necessary strength, durability, and versatility required for the manufacturing of various transportation vehicles and infrastructure. Their contribution ensures the safety, reliability, and efficiency of transportation systems, making them indispensable in the modern world.

- Q: How are steel coils used in the production of electrical devices?

- The production of electrical devices heavily relies on steel coils. These coils, typically made from high-quality steel, are precisely wound into a circular shape. They have a crucial function in various electrical devices, including transformers, motors, generators, and inductors. Transformers, for instance, heavily rely on steel coils. These devices are essential for adjusting voltage levels in electrical circuits. They consist of two separate coils, the primary and secondary coils, which are wound around a magnetic core. The steel coil plays a vital role in providing stability and support to the windings, ensuring proper alignment and preventing any deformation. Moreover, the high magnetic permeability of steel helps enhance the efficiency of energy transfer between the coils. In motors and generators, steel coils are utilized to create magnetic fields that either generate mechanical energy or convert it into electrical energy. These coils are wound around an armature or rotor, which rotates within a magnetic field created by a stator. As the current flows through the coils, a magnetic field is produced, resulting in the rotation of the armature or the generation of electrical power. Steel coils are also used in inductors, another type of electrical device. Inductors consist of a coil of wire wound around a core material, often made of steel. Steel coils in inductors help increase the inductance, which measures the device's ability to store energy in a magnetic field. By storing energy in this manner, inductors can regulate currents, filter out noise, and provide stability to electrical circuits. All in all, steel coils are indispensable in the production of electrical devices. They provide stability, support, and enhance the necessary magnetic properties for efficient functioning. Without steel coils, the performance and reliability of electrical devices like transformers, motors, generators, and inductors would be greatly compromised.

- Q: How are steel coils unloaded from a truck or ship?

- Steel coils are typically unloaded from a truck or ship using specialized equipment such as cranes, forklifts, or coil lifters. The coils are carefully lifted off the truck or ship and then placed onto a designated area in the storage yard or warehouse using the appropriate machinery.

- Q: How do we use steel ?plesase answer, its for homework xxx

- Strength of metals is normally measured by the tensile strength as the main measure although this is not the only property as hardness is another big factor. Basically, iron is soft and steel is hard. Plain iron is stretchy and does not corrode quickly, whereas steel is much stiffer and corrodes more quickly. The tensile strength of cold worked iron is about half that of an average steel, likewise the hardness is about half that of steel too. Pure iron, which is rarely used, is even weaker and softer again and a bit more like softer materials like copper and aluminium. Where confusion comes in is that there is another iron - Cast Iron - which is totally different to both iron and steel. Cast iron is very hard and tough but incredibly brittle so its properties are very different.

- Q: i need a company that sells strong steel doors because my neighbors apartment was broken into. I need a strong steel door for the outside of the home, where you first enter. please list places in the US, or in NY.

- The okorder /

- Q: I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI boots, but would very much love to be able to rock a pair of cruelty free boots/shoes on the job!It does not have to be certified vegan just all man-made materials and no leather/sued and other such stuff where animals have to die. It would make me no better than the massive slaughterhouse industries and such. Valueing money of ver live/morals. I don't want one of the first things I need to do in my manufacturing job is compromising my morals. :3So if you know of an ANSI vegan friendly boot brand PLEASE TELL ME! *gets on knees begging*Money isn't really an option for me, I'll just continue borrowing my dad's boots till I save up enough!Thanks in advance! :D

- This Site Might Help You. RE: Vegan ANSI Steel Toes? I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI...

- Q: What are the common surface treatments for galvanized steel coils?

- Galvanized steel coils can undergo various surface treatments to improve their corrosion resistance and appearance. Passivation is one such treatment, where a protective material like zinc phosphate or chromate is applied to create a barrier against moisture and atmospheric elements. This also enhances the adhesion of subsequent coatings or paints. Another treatment is chromate coating, which involves applying a thin layer of chromate to the steel surface. This provides extra protection against corrosion and enhances the steel's appearance. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is a common treatment that involves applying a thin layer of oil to prevent rust and corrosion during storage and transportation. It also offers temporary protection against moisture and other environmental factors until the steel is further processed or used. These surface treatments are widely used to improve the performance, durability, and appearance of galvanized steel coils, ensuring they can withstand harsh conditions and maintain their quality over time.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through visual examination and various non-destructive testing techniques. These include measuring the dimensions and weight of the coils, checking for any surface defects or damages, and conducting magnetic particle or ultrasonic testing to detect any internal flaws or irregularities. Additionally, the coils may undergo chemical composition analysis to ensure uniformity in the steel's properties.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls With Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords