Tabel Formwork Systems for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

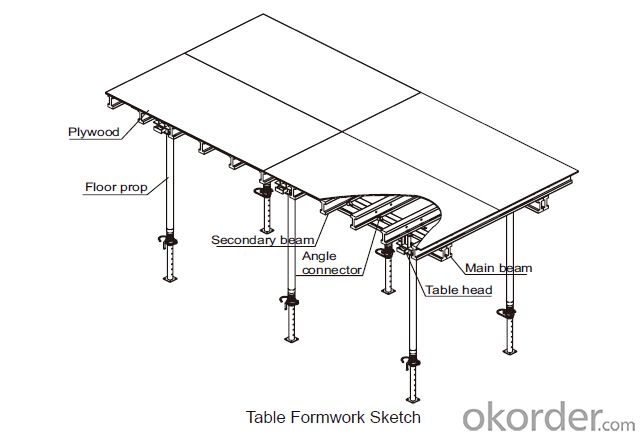

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: What are the different sizes available for steel formwork panels?

- Steel formwork panels are available in various sizes to accommodate different construction needs. The sizes typically range from 1.2 meters to 2.4 meters in width and 1.0 meter to 3.0 meters in height. These dimensions are commonly used in the industry, but manufacturers can also customize the sizes to meet specific project requirements. The selection of the appropriate size depends on factors such as the size of the structure being built, the desired concrete finish, and the ease of transportation and installation. It is important to consult with a professional or supplier to determine the most suitable size for a particular construction project.

- Q: How does steel formwork improve the quality of concrete structures?

- Steel formwork is widely employed in the construction industry due to its numerous advantages, which greatly enhance the quality of concrete structures. Here are several ways in which steel formwork improves the quality of concrete structures: 1. Superior Form Stability: Compared to traditional wooden formwork, steel formwork offers enhanced form stability. It is more rigid and less prone to warping or distortion, guaranteeing that the concrete is poured into an accurate and consistent shape. This results in straighter walls, smoother surfaces, and overall better structural integrity. 2. Increased Durability: Steel formwork is highly durable and capable of withstanding the harsh conditions of construction sites. Unlike wooden formwork, it does not rot, decay, or easily sustain damage. Its long lifespan allows for multiple reuses, thereby reducing costs and waste. This durability translates into stronger and longer-lasting concrete structures. 3. Precise Dimensions: Steel formwork is manufactured with high precision, enabling accurate and consistent dimensions in concrete structures. It facilitates achieving the desired shape, size, and alignment of elements. This accuracy is crucial in ensuring that the structure meets required specifications and architectural designs, resulting in a high-quality finished product. 4. Improved Surface Finish: Steel formwork provides a smooth and even surface finish to concrete structures. The design of steel panels minimizes surface imperfections and prevents leakage of the concrete mixture. This results in visually appealing structures with uniform finishes, which reduces the need for additional plastering or finishing work. 5. Enhanced Safety: Steel formwork enhances safety during the construction process. Its sturdy and rigid nature provides a stable platform for workers to pour and work with concrete. The risk of accidents, such as formwork failure or collapse, is significantly reduced with steel formwork, ensuring the safety of workers and the integrity of the structure. In conclusion, the utilization of steel formwork in concrete construction brings multiple benefits that contribute to the improvement of structure quality. With its form stability, durability, precise dimensions, improved surface finish, and enhanced safety, steel formwork plays a vital role in ensuring the integrity, aesthetics, and longevity of concrete structures.

- Q: How does steel formwork handle different concrete crack control measures?

- Steel formwork is an excellent choice for accommodating different concrete crack control measures due to its inherent strength and durability. It is capable of withstanding the pressure exerted during the curing process, reducing the risk of cracks caused by formwork deflection. Additionally, steel formwork allows for tighter control over the placement of reinforcement and use of expansion joints, which are effective measures for preventing cracks. Overall, steel formwork provides a reliable and versatile solution for addressing various crack control measures in concrete construction.

- Q: How does steel formwork affect the overall construction waste management?

- Steel formwork is renowned for its durability and reusability, which can have a significant positive impact on construction waste management. Firstly, the multiple reuse of steel formwork reduces the necessity for new formwork materials for each construction project, thus decreasing waste production during construction and lessening the demand for raw materials like timber, commonly utilized in traditional formwork systems. Furthermore, the high strength and stability of steel formwork enable efficient and precise construction, thereby minimizing the occurrence of errors or mistakes during the construction process. This results in reduced rework and waste. Moreover, steel formwork offers easy dismantling and reassembly, allowing for design and construction flexibility and minimizing waste that would otherwise be generated by fixed or permanent formwork systems. Additionally, at the end of its life cycle, steel formwork is recyclable. Steel is widely recognized as one of the most recycled materials globally, and its recycling process is energy-efficient with minimal environmental impact. By opting for steel formwork, construction projects can contribute to a circular economy, ensuring that construction materials can be recycled and reused rather than being disposed of in landfills. To conclude, steel formwork positively impacts construction waste management by reducing waste generation during construction, minimizing the need for new materials, facilitating efficient construction processes, and promoting recycling at the end of its life cycle. These advantages make steel formwork a sustainable choice for construction projects that aim to minimize environmental impact and adopt responsible waste management practices.

- Q: How does steel formwork compare to wooden formwork in terms of cost?

- Steel formwork generally tends to be more expensive than wooden formwork in terms of upfront costs. This is mainly due to the higher cost of materials and manufacturing processes involved in producing steel formwork. Additionally, steel formwork often requires specialized equipment and skilled labor for installation, which can further contribute to its higher cost. On the other hand, wooden formwork is typically more affordable in terms of initial investment. Wood is widely available and relatively inexpensive compared to steel. Furthermore, wooden formwork can be easily fabricated and customized on-site, reducing the need for additional expenses associated with specialized manufacturing. However, it is important to consider the long-term costs when comparing steel and wooden formwork. Steel formwork has the advantage of being more durable and resilient to wear and tear. It can withstand multiple uses and is less susceptible to damage from moisture, insects, and other environmental factors. This means that steel formwork can be used repeatedly, reducing the need for frequent replacement and lowering long-term costs. Wooden formwork, on the other hand, may require regular maintenance, repairs, and eventual replacement due to its susceptibility to damage and deterioration over time. This can result in additional costs over the lifespan of the project. In conclusion, while steel formwork may be initially more expensive than wooden formwork, its durability and longevity can lead to cost savings in the long run. However, the choice between steel and wooden formwork ultimately depends on the specific project requirements, budget, and other factors such as time constraints and availability of resources.

- Q: How does steel formwork perform in fire-resistant structures?

- Steel formwork performs exceptionally well in fire-resistant structures. The inherent properties of steel, such as its high melting point and strength, make it an ideal material for withstanding high temperatures and structural integrity during a fire event. Firstly, steel formwork is non-combustible, meaning it does not contribute to the spread or intensity of the fire. It does not burn or release harmful gases when exposed to flames, unlike some other construction materials. This characteristic helps to prevent the rapid spread of fire within the structure, providing valuable time for evacuation and fire suppression. Moreover, steel has a high melting point compared to other materials commonly used in formwork, such as wood or plastic. This property allows steel formwork to maintain its structural integrity even when exposed to intense heat. It can withstand temperatures well above 1000°C (1832°F) without significant deformation or collapse, ensuring the stability of the structure and reducing the risk of sudden structural failure during a fire. Additionally, steel formwork has excellent load-bearing capabilities, even at high temperatures. This is crucial in fire-resistant structures as it allows the building to maintain its structural capacity when exposed to fire. The ability of steel formwork to bear the weight of the structure, even when compromised by fire, helps to prevent structural collapse and ensures the safety of occupants and emergency responders. Furthermore, steel formwork is durable and long-lasting, which is important in fire-resistant structures. It can withstand the effects of fire, such as thermal expansion and contraction, without significant damage. This durability ensures that the formwork can be reused or remain in place for future fire events, providing ongoing fire protection for the structure. In conclusion, steel formwork performs exceptionally well in fire-resistant structures. Its non-combustible nature, high melting point, load-bearing capabilities, and durability make it a reliable choice for maintaining the structural integrity and safety of the building during a fire.

- Q: How does steel formwork handle moisture and humidity?

- Steel formwork is highly resistant to moisture and humidity due to its non-porous nature. Unlike other materials, steel does not absorb water, preventing any damage caused by swelling, warping, or decay. Additionally, steel formwork is coated with protective layers, such as galvanization or epoxy, which further enhance its resistance to moisture and humidity, ensuring its durability and longevity.

- Q: What are the considerations when designing steel formwork for foundations?

- There are several important factors to consider when designing steel formwork for foundations. Firstly, it is crucial to carefully calculate and design the load-bearing capacity of the formwork to ensure it can support the weight of the concrete being poured. The strength and thickness of the steel used will play a significant role in determining its ability to withstand the pressure and weight of the liquid concrete without deforming or collapsing. Another important consideration is accurately replicating the desired shape and dimensions of the foundation. This requires careful planning and measurement to ensure the formwork is properly aligned and positioned before pouring the concrete. Any inaccuracies in the formwork can compromise the structural integrity of the building. Efficiency of installation and removal is also a key consideration. Modular or adjustable steel formwork systems can greatly improve the construction process by allowing for easy assembly and disassembly. This reduces labor and time requirements. Additionally, provisions should be made for easy access to the foundation for inspections or repairs during and after construction. Finally, the durability and longevity of the steel formwork should be taken into account. While steel is known for its strength and durability, protective measures should be implemented to prevent corrosion. Applying protective coatings or using galvanized steel can help prevent rust and extend the lifespan of the formwork. In conclusion, when designing steel formwork for foundations, it is essential to consider factors such as load-bearing capacity, accuracy of shape and size, ease of installation and removal, and durability to ensure a successful and structurally sound foundation.

- Q: Can steel formwork be used for underground culverts?

- Yes, steel formwork can be used for underground culverts. Steel formwork is durable and strong, making it suitable for withstanding the pressure and weight of the surrounding soil and water in underground culverts. It provides a stable and rigid structure that can be easily assembled and disassembled, allowing for efficient construction and maintenance of underground culverts.

- Q: What type of finishes can be achieved with steel formwork?

- Steel formwork offers a variety of finishes for concrete structures, making it a versatile option. Smooth finishes can be achieved using steel formwork, giving the concrete a seamless and uniform appearance. This finish is ideal for architectural purposes or when a clean and modern look is desired. Textured finishes are also possible with steel formwork. Different textures, such as wood grain or brick patterns, can be incorporated onto the surface of the formwork, transferring them onto the concrete during casting. This creates an aesthetically pleasing finish that adds depth and interest to the structure. Furthermore, steel formwork allows for patterned surfaces to be created. Intricate designs or motifs can be incorporated onto the formwork panels, resulting in unique and decorative finishes on the concrete surface. This type of finish is often used in architectural applications that require specific designs or branding elements. In conclusion, steel formwork provides the flexibility and precision needed to achieve a wide range of finishes for concrete structures. Whether it's a smooth, textured, or patterned finish, steel formwork enables the desired aesthetic outcome to be realized.

Send your message to us

Tabel Formwork Systems for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches