Tabel Formwork System for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

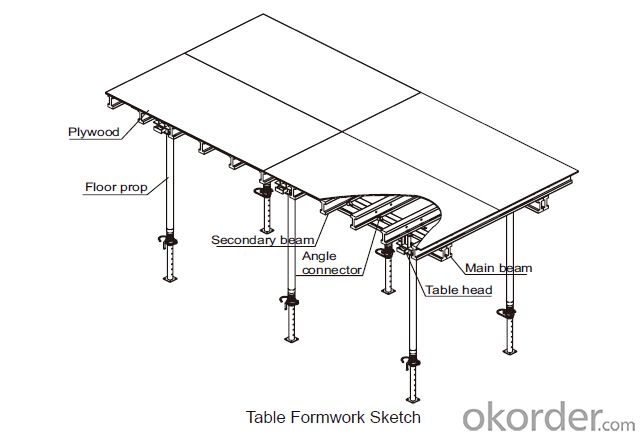

OKorder is offering high quality Building Scaffolding Table Formwork Systems at great prices with worldwide shipping. Table formwork is the most typical application, suitable for use with slabs or timber beam. Slab formwork is lightweight easy to erect and economical. Our supplier is a world-class manufacturer of scaffolding, and our products are utilized the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets.

Product Applications:

Building Scaffolding Table Formwork Systems are for use in interior or exterior applications, and are designed to endure everyday use around a construction sites and remodeling projects.

Product Advantages:

OKorder's Building Scaffolding Table Formwork Systems help you get your project off the ground, with improved safety, economical construction and standardized parts.

Main Product Features:

· Improved safety with handrails

· Easy assembly

· Flexible structure, suitable for varied support systems

· Increases construction efficiency

· Formwork forklift and trolley compatible

· Flexible application with stand alone props

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are the capacity requirements for all scaffolds?

A3: Each scaffold and scaffold component must support without failure its own weight and at least 4 times the maximum intended load applied or transmitted to it. Scaffolds and scaffold components must not be loaded in excess of their maximum intended loads or rated capacities, whichever is less. Load carrying timber members should be a minimum of 1,500 lb-f/in² construction grade lumber.

Q4: Should I use steel scaffolding or aluminum scaffold?

A4: If your job will run 6-8 weeks or more, steel scaffolding will actually be cheaper for you. Projects that run for a few hours to a few weeks are generally more practical and economical to do with aluminum scaffolding.

Q5: Is aluminum scaffold suitable for outdoor use?

A5: Aluminum scaffolding is designed to endure any weather conditions. It is tested to handle the cold winters of North America and Europe, and the extreme heats of Australia and Africa.

Q6: When should I order caster wheels versus leveling jacks?

A6: Order wheels for inside use. We do not recommend them outside unless on hard surface such as concrete or asphalt. Use level jacks outside or inside. Level jacks offer adjustability of the platform height of greater than 1500px.

Images:

- Q: How does steel formwork contribute to the overall durability of the structure?

- Steel formwork contributes to the overall durability of a structure in several ways. Firstly, steel is a strong and rigid material that provides excellent support and stability during the concrete pouring process. This ensures that the structure maintains its shape and form accurately, minimizing any potential deformations or cracks. Additionally, steel formwork is highly resistant to corrosion, which helps protect the concrete from moisture and other environmental factors that can weaken its integrity over time. Furthermore, steel formwork can be easily reused multiple times, reducing material waste and increasing cost-effectiveness. Overall, the use of steel formwork enhances the structural strength and longevity of the building, ensuring its durability for years to come.

- Q: What are the different types of safety systems used with steel formwork?

- There are several types of safety systems used with steel formwork, including guardrails, safety nets, edge protection systems, fall arrest systems, and personal protective equipment (PPE). These systems are designed to prevent falls, provide barriers against hazardous areas, and protect workers from potential accidents or injuries while working with steel formwork.

- Q: What are the different types of scaffolding used with steel formwork?

- Steel formwork can be used with various types of scaffolding, each having its own unique features and advantages. 1. Tube and Coupler Scaffolding is widely utilized with steel formwork. It comprises vertical tubes connected by couplers, enabling easy adjustment and flexibility in terms of height and width. It is renowned for its strength and stability, making it suitable for heavy-duty construction projects. 2. H-frame Scaffolding, similar to the tube and coupler system, employs H-shaped frames instead of vertical tubes. It is lightweight and easily assembled and disassembled, making it ideal for small-scale construction projects or areas with limited space. 3. Cuplock Scaffolding is a modular system that utilizes pre-fabricated components, including vertical standards with cup joints and horizontal ledgers. Its quick assembly and disassembly make it a popular choice for time-sensitive projects. Additionally, it is known for its versatility, as it can be used for both straight and curved structures. 4. Ringlock Scaffolding, like cuplock scaffolding, uses a rosette joint system instead of cups. This allows for greater flexibility in assembling and adjusting the scaffolding. With its durability and high load-bearing capacity, ringlock scaffolding is suitable for heavy construction projects. 5. Kwikstage Scaffolding is another modular system that employs pre-fabricated components, including standards, ledgers, and transoms. It offers excellent flexibility in terms of height and width adjustments and can be quickly assembled and dismantled. Kwikstage scaffolding is commonly used in construction projects requiring frequent movement and repositioning of scaffolding. In conclusion, the choice of scaffolding for steel formwork depends on specific project requirements, such as load-bearing capacity, flexibility, ease of assembly, and durability.

- Q: How does steel formwork contribute to the overall stability of a structure?

- Steel formwork is a crucial component in the construction industry that greatly contributes to the overall stability of a structure. It is widely used in the casting of concrete elements such as walls, slabs, columns, and beams. One of the primary ways that steel formwork enhances stability is by providing a rigid and robust framework for the pouring and setting of concrete. The steel panels and frames are designed to withstand the pressure exerted by the wet concrete, ensuring that it retains its shape and does not deform during the curing process. This helps to prevent any potential structural deficiencies or unevenness that may compromise the stability of the final structure. Furthermore, steel formwork offers exceptional strength and durability, making it suitable for various construction projects. The high tensile strength of steel allows it to withstand heavy loads, which is particularly important in the construction of large-scale structures with significant weight-bearing requirements. This strength also ensures that the formwork can be reused multiple times, reducing the overall construction costs and environmental impact. Additionally, steel formwork provides excellent dimensional stability, meaning it maintains its shape and dimensions throughout the construction process. This characteristic is crucial in ensuring the accuracy and consistency of the structure, as any deviations or variations in shape may result in structural instability. Moreover, steel formwork is highly resistant to moisture and other environmental factors, which can be detrimental to the stability of a structure. Its corrosion-resistant properties make it suitable for use in outdoor construction sites, where exposure to rain, humidity, and other elements may occur. This resistance to corrosion ensures that the formwork remains intact and does not weaken over time, thereby contributing to the long-term stability of the structure. In conclusion, steel formwork plays a vital role in enhancing the overall stability of a structure. Its rigid and robust framework, combined with its strength, durability, dimensional stability, and resistance to environmental factors, ensures that the concrete is properly formed and retains its structural integrity. By providing a stable and secure foundation for the construction process, steel formwork significantly contributes to the stability and safety of the final structure.

- Q: What are the considerations when designing steel formwork for underground parking structures?

- When designing steel formwork for underground parking structures, there are several important considerations that need to be taken into account. These considerations include: 1. Structural Stability: Underground parking structures experience significant loads from the surrounding soil, as well as the weight of the vehicles they will accommodate. It is crucial to design the steel formwork in a way that ensures structural stability and can withstand these loads. 2. Water Resistance: Underground parking structures are susceptible to water infiltration, especially in areas with high groundwater levels. The steel formwork should be designed to be watertight, with proper sealing and waterproofing measures in place, to prevent water damage and maintain the integrity of the structure. 3. Fire Resistance: Fire safety is of utmost importance in underground parking structures. The steel formwork should be designed to meet the required fire resistance standards and provide adequate protection against fire hazards. 4. Durability: Underground parking structures are subject to constant traffic and wear and tear. The steel formwork should be designed to be durable and able to withstand the load and stress imposed by vehicles, as well as any potential impact from collisions or accidents. 5. Accessibility and Efficiency: The design of the steel formwork should take into consideration the accessibility of the parking structure, including the layout of ramps, entrances, and exits. It should also aim to maximize space utilization and efficiency, providing adequate parking slots without compromising safety or ease of use. 6. Maintenance and Repairs: The design should also consider the ease of maintenance and repairs. Accessible areas for inspection, maintenance, and repairs should be incorporated into the formwork design to ensure that any necessary maintenance or repairs can be carried out efficiently. 7. Cost-effectiveness: Finally, the design should strike a balance between meeting all the necessary requirements and being cost-effective. It is essential to consider the overall cost of materials, construction, and maintenance when designing the steel formwork for underground parking structures. By carefully considering these considerations, engineers and designers can create effective and efficient steel formwork for underground parking structures that meet all the necessary requirements for safety, durability, and functionality.

- Q: How does steel formwork affect the overall moisture resistance of the structure?

- The overall moisture resistance of a structure can be affected in both positive and negative ways by steel formwork. On the positive side, steel formwork acts as a rigid and impermeable barrier that prevents water from penetrating the concrete during construction. This is especially beneficial in areas with high moisture levels or where water infiltration could compromise the structure's integrity. However, steel formwork can also pose challenges to moisture resistance. Unlike wood or plastic formwork, steel is susceptible to corrosion when exposed to moisture for extended periods. If the steel formwork is not properly protected or maintained, it can rust and weaken its structural integrity, potentially compromising the overall moisture resistance of the structure. In addition, the use of steel formwork can create a thermal bridge within the structure. Steel has high thermal conductivity, meaning it can easily transfer heat or cold from one side to the other. This can result in condensation problems and potential moisture issues if proper insulation or vapor barriers are not implemented. To address these potential drawbacks, it is crucial to apply suitable anti-corrosion coatings and ensure proper maintenance of the steel formwork. Furthermore, adequate insulation and vapor barrier systems should be installed to minimize the impact of thermal bridging and prevent condensation problems. In conclusion, although steel formwork provides initial protection against moisture during construction, it is important to address its vulnerabilities to corrosion and thermal bridging in order to maintain the structure's overall moisture resistance in the long term.

- Q: Are there any specific considerations for using steel formwork in areas with high traffic loads?

- There are various factors to take into account when using steel formwork in areas with high traffic loads. Firstly, it is crucial to carefully assess the strength and durability of the steel formwork to ensure it can withstand the heavy loads and constant traffic. Steel formwork is renowned for its robustness and load-bearing capacity, making it suitable for such applications. However, it is important to select the appropriate type and grade of steel that can endure the specific traffic loads in the area. Secondly, it is imperative to entrust the design and construction of the formwork system to experienced professionals who understand the requirements of high traffic loads. Adequate reinforcement and bracing should be incorporated to enhance the strength and stability of the formwork structure. This may involve utilizing additional steel supports or beams to distribute the loads more effectively. Moreover, the connections and joints between different formwork elements should be meticulously designed and constructed to ensure they can withstand the heavy traffic loads without any failures. Welding or bolting techniques may be employed to enhance the structural integrity of the formwork system. Additionally, regular inspection and maintenance of the steel formwork should be conducted to identify any indications of wear and tear or damage caused by the high traffic loads. Any damaged or weakened sections should be promptly repaired or reinforced to avoid any safety hazards. Lastly, it is crucial to consider the impact of the high traffic loads on the poured concrete. The concrete mix and pouring techniques should be carefully chosen to ensure they can withstand the dynamic loads caused by heavy traffic. Reinforcement measures such as using steel rebar or fiber reinforcement can also be considered to augment the strength and durability of the concrete. In conclusion, when employing steel formwork in areas with high traffic loads, it is essential to consider the strength and durability of the formwork, design and construction techniques, connections and joints, regular inspection and maintenance, as well as the impact on the concrete. By taking these specific considerations into account, the steel formwork can provide a secure and dependable solution for construction projects in high traffic areas.

- Q: How does steel formwork handle different concrete surface slip resistance?

- Steel formwork is a versatile and strong material that is commonly used in construction projects to shape and support concrete during the curing process. When it comes to handling different concrete surface slip resistance, steel formwork offers several advantages. Firstly, steel formwork provides a smooth and even surface for pouring concrete, which helps to minimize variations in slip resistance. Unlike other materials such as wood, steel does not warp or deform, ensuring consistent contact between the formwork and the concrete. This uniformity in contact helps to create a more consistent concrete surface, reducing the chances of uneven slip resistance. Additionally, steel formwork allows for the use of various surface treatments and coatings that can enhance slip resistance. For instance, anti-slip coatings or aggregates can be added to the formwork surface before pouring the concrete, creating a textured surface that improves traction. These treatments can be customized to meet specific slip resistance requirements, allowing for flexibility in design. Moreover, steel formwork is highly durable and resistant to wear and tear. This durability ensures that the formwork maintains its structural integrity throughout the concrete pouring process, minimizing the chances of surface irregularities that could affect slip resistance. Furthermore, steel formwork can be easily cleaned and maintained, ensuring that any contaminants or debris that could affect slip resistance are promptly addressed. In summary, steel formwork is able to handle different concrete surface slip resistance by providing a smooth and consistent surface, allowing for customization through various surface treatments, and maintaining durability to prevent surface irregularities. Its strength and versatility make steel formwork a reliable choice for construction projects where slip resistance is a concern.

- Q: How does steel formwork affect the concrete pouring process?

- Steel formwork plays a crucial role in the concrete pouring process by providing a sturdy and reliable support structure for the wet concrete. It offers several advantages over other types of formwork, such as timber or plastic. Firstly, steel formwork is highly durable and can withstand the pressure exerted by the wet concrete without warping or deforming. This ensures that the formwork maintains its shape and dimensions, resulting in a finished concrete structure that is accurate and precise. This is particularly important for projects with complex shapes or intricate designs. Additionally, steel formwork is reusable, making it a cost-effective solution for construction projects. Unlike timber or plastic formwork, steel can be used multiple times, reducing the overall project expenses. It also contributes to sustainability by minimizing waste and reducing the environmental impact associated with disposable formwork materials. Another advantage of steel formwork is its ability to provide a smooth surface finish to the concrete. The steel panels are manufactured with high precision, resulting in a uniform and even surface texture on the poured concrete. This is particularly beneficial for projects that require a high-quality finish, such as architectural structures or exposed concrete surfaces. Furthermore, steel formwork offers excellent stability and support during the pouring process. Its rigid structure prevents any movement or shifting of the formwork, ensuring that the concrete is poured accurately and evenly. This is crucial for maintaining the structural integrity of the concrete and preventing any potential defects or weaknesses. In summary, steel formwork significantly affects the concrete pouring process by providing durability, reusability, smooth surface finish, and stability. It ensures that the concrete structure is formed accurately and precisely, resulting in a high-quality finished product.

- Q: What are the different types of steel formwork joint solutions?

- There are several types of steel formwork joint solutions, including lap joints, butt joints, corner joints, and T-joints. These solutions are used in construction to ensure the stability and integrity of the formwork system during concrete pouring.

Send your message to us

Tabel Formwork System for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches