Tabel formwork system for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

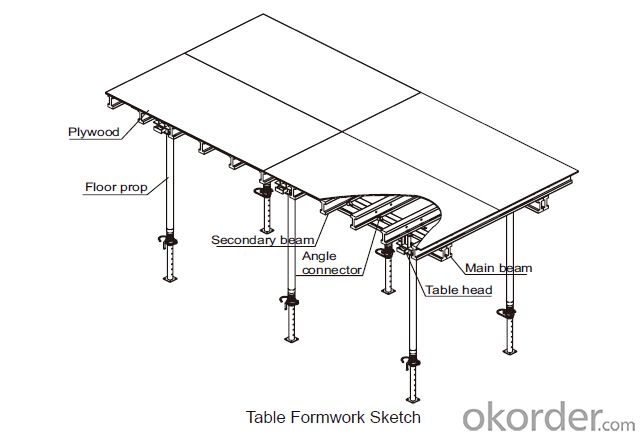

OKorder is offering high quality Building Scaffolding Table Formwork Systems at great prices with worldwide shipping. Table formwork is the most typical application, suitable for use with slabs or timber beam. Slab formwork is lightweight easy to erect and economical. Our supplier is a world-class manufacturer of scaffolding, and our products are utilized the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets.

Product Applications:

Building Scaffolding Table Formwork Systems are for use in interior or exterior applications, and are designed to endure everyday use around a construction sites and remodeling projects.

Product Advantages:

OKorder's Building Scaffolding Table Formwork Systems help you get your project off the ground, with improved safety, economical construction and standardized parts.

Main Product Features:

· Improved safety with handrails

· Easy assembly

· Flexible structure, suitable for varied support systems

· Increases construction efficiency

· Formwork forklift and trolley compatible

· Flexible application with stand alone props

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are the capacity requirements for all scaffolds?

A3: Each scaffold and scaffold component must support without failure its own weight and at least 4 times the maximum intended load applied or transmitted to it. Scaffolds and scaffold components must not be loaded in excess of their maximum intended loads or rated capacities, whichever is less. Load carrying timber members should be a minimum of 1,500 lb-f/in² construction grade lumber.

Q4: Should I use steel scaffolding or aluminum scaffold?

A4: If your job will run 6-8 weeks or more, steel scaffolding will actually be cheaper for you. Projects that run for a few hours to a few weeks are generally more practical and economical to do with aluminum scaffolding.

Q5: Is aluminum scaffold suitable for outdoor use?

A5: Aluminum scaffolding is designed to endure any weather conditions. It is tested to handle the cold winters of North America and Europe, and the extreme heats of Australia and Africa.

Q6: When should I order caster wheels versus leveling jacks?

A6: Order wheels for inside use. We do not recommend them outside unless on hard surface such as concrete or asphalt. Use level jacks outside or inside. Level jacks offer adjustability of the platform height of greater than 1500px.

Images:

- Q: Can steel formwork be used for architectural concrete columns?

- Yes, steel formwork can be used for architectural concrete columns. Steel formwork is known for its strength and durability, making it a suitable choice for constructing concrete columns. It provides a rigid structure that can withstand the pressure exerted by the wet concrete during pouring and curing. Steel formwork also allows for precise shaping and detailing, enabling architects to create intricate designs and textures on the surface of the concrete columns. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for projects that require multiple concrete columns. However, it is important to ensure that the steel formwork is properly coated or treated to prevent corrosion and ensure its longevity.

- Q: Can steel formwork be used in underground structures?

- Yes, steel formwork can be used in underground structures. Steel formwork is a versatile and durable construction material that can withstand the challenging conditions of underground structures. It offers excellent strength and stability, making it suitable for constructing walls, columns, and slabs in underground spaces. One of the key advantages of steel formwork is its ability to resist the pressure exerted by the surrounding soil and water. Underground structures often face high hydrostatic pressure, and steel formwork can easily withstand this pressure without deforming or collapsing. This ensures the safety and stability of the structure. Additionally, steel formwork is reusable, which makes it a cost-effective choice for underground construction projects. Its robustness allows it to withstand multiple uses, reducing the need for frequent replacements and lowering overall construction costs. Moreover, steel formwork offers flexibility in design and can be easily customized to meet specific project requirements. It can be fabricated into various shapes and sizes, allowing for the creation of complex geometries in underground structures. However, it is important to note that steel formwork requires proper surface treatment to protect it from corrosion in the underground environment. Special coatings or galvanization can be applied to prevent rusting and prolong the lifespan of the formwork. Overall, steel formwork is a suitable choice for underground structures due to its strength, durability, reusability, and flexibility in design. It can effectively withstand the challenges posed by the underground environment and ensure the long-term stability and safety of the structure.

- Q: How does steel formwork affect the overall project coordination and scheduling?

- The overall project coordination and scheduling can be significantly impacted by steel formwork. Firstly, steel formwork is renowned for its durability and strength, enabling it to withstand the pressure and weight of concrete pouring. Consequently, construction can proceed at a faster pace, minimizing delays and ensuring the project remains on schedule. Moreover, steel formwork offers a remarkable level of accuracy and precision in shaping and dimensioning the concrete structures. This precision reduces the need for rework and adjustments, saving time and preventing disruptions to the schedule. Regarding project coordination, steel formwork promotes better communication and collaboration among the different teams involved in the construction process. The standardized and modular nature of steel formwork guarantees that all parties work with the same materials and dimensions, facilitating smoother coordination and reducing conflicts. Additionally, steel formwork is reusable, allowing it to be dismantled and used for multiple projects. This not only reduces material costs but also enhances project scheduling by enabling concurrent construction activities. The ability to reuse steel formwork also minimizes the environmental impact of construction projects, aligning with sustainable practices. In summary, steel formwork enhances project coordination and scheduling by providing durability, accuracy, and reusability. Its efficiency and versatility contribute to faster construction timelines, reduced rework, and improved communication among various project stakeholders.

- Q: How does steel formwork affect the overall safety of construction workers?

- Steel formwork can greatly enhance the overall safety of construction workers. Firstly, steel formwork is known for its durability and strength, which makes it highly resistant to damage or collapse during the construction process. This ensures that workers are protected from potential accidents caused by the formwork failing or collapsing. Additionally, steel formwork is designed to be structurally stable, providing a secure and stable platform for workers to carry out their tasks. This stability reduces the risk of slips, trips, and falls, which are among the most common causes of accidents in construction sites. With a stable formwork system, workers can confidently move around and work at heights without the fear of the platform giving way. Furthermore, steel formwork is designed to be modular and easily assembled, allowing for quick and efficient construction processes. This reduces the time workers spend on the construction site, minimizing their exposure to potential hazards and risks. By reducing the duration of the project, steel formwork also decreases the overall fatigue and stress levels of workers, leading to increased alertness and improved safety. Another safety advantage of steel formwork is its resistance to fire. Steel does not burn or contribute to the spread of fire, which adds an extra layer of protection for construction workers in case of fire accidents on-site. This feature significantly reduces the risk of injuries or fatalities due to fire incidents, ensuring the safety of workers. Overall, the use of steel formwork in construction significantly enhances the safety of workers. Its durability, stability, quick assembly, and fire resistance properties all contribute to creating a safer working environment, reducing the likelihood of accidents and injuries. By investing in steel formwork, construction companies prioritize the well-being of their workers and promote a culture of safety on the construction site.

- Q: What are the disadvantages of using steel formwork?

- One disadvantage of using steel formwork is its relatively high cost compared to other types of formwork materials. Additionally, steel formwork is heavy and requires special equipment for handling and installation, making it less convenient to transport and set up on construction sites. Moreover, steel formwork needs to be properly maintained to prevent rusting and corrosion, which adds to the overall maintenance cost. Lastly, steel formwork may not be suitable for complex and intricate architectural designs that require flexible formwork systems.

- Q: How does steel formwork handle concrete bleeding?

- Steel formwork handles concrete bleeding by providing a strong and rigid structure that prevents excessive flow of water and cement particles from the concrete mixture. The smooth surface of steel formwork also helps in reducing the bleeding by allowing the trapped air and excess water to escape easily. Overall, steel formwork ensures better control over concrete bleeding and helps in achieving a more uniform and compacted concrete structure.

- Q: How does steel formwork affect the overall cost of concrete construction?

- The overall cost of concrete construction can be greatly impacted by the use of steel formwork. Although the initial investment in steel formwork may be more expensive than traditional wood formwork, the long-term benefits and cost savings outweigh this initial expense. One of the key advantages of steel formwork is its durability and ability to be used multiple times. Unlike wood formwork, steel formwork can be reused, which reduces the need for frequent replacements and lowers material costs. Additionally, steel formwork is resistant to warping, shrinking, and swelling, ensuring that the concrete structure maintains its intended shape and dimensions. This saves both time and money by eliminating the need for rework and adjustments. The strength and stability of steel formwork also contribute to cost savings. It can withstand higher concrete pressures, allowing for the construction of taller and more complex structures without the need for extra reinforcements or additional support systems. This decreases the amount of materials required and minimizes labor costs. Moreover, steel formwork provides a smooth and even surface finish, reducing the need for additional surface treatments or finishes. This not only saves costs on materials but also speeds up construction time by eliminating the need for extensive surface preparation. Another cost-saving aspect is the ease of assembly and disassembly associated with steel formwork. The efficient design and standardized components of steel formwork make it quick and easy to install and dismantle, reducing labor costs and improving overall productivity. In summary, even though steel formwork may have a higher initial cost, its durability, reusability, strength, stability, and ease of use can lead to significant cost savings in terms of material, labor, and time. The efficiency and longevity of steel formwork make it a cost-effective choice for concrete construction projects.

- Q: What are the different types of steel formwork ties and connectors?

- There are various types of steel formwork ties and connectors used in construction projects. Some common types include loop ties, flat ties, wedge bolts, formwork clamps, and snap ties. These ties and connectors are used to secure the formwork panels together, ensuring stability and alignment during the concrete pouring process.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers durability and strength, making it suitable for creating precise and complex shapes required for precast concrete columns. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for precast concrete column production.

- Q: Can steel formwork be used for residential tower construction projects?

- Yes, steel formwork can be used for residential tower construction projects. Steel formwork is a popular choice in the construction industry due to its durability and versatility. It is especially suitable for high-rise structures like residential towers, where the formwork needs to withstand high concrete pressures and provide a smooth finish. Steel formwork is known for its ability to be reused multiple times, making it a cost-effective option for large-scale projects. It can be easily assembled and disassembled, which allows for efficient construction schedules. Additionally, steel formwork provides excellent support during the pouring and setting of concrete, ensuring precise dimensions and alignment. Residential tower construction projects often require fast construction cycles, and steel formwork helps in achieving this by allowing for quick and efficient concrete pouring and formwork removal. The use of steel formwork also reduces the need for skilled labor, as it can be easily handled and manipulated. However, it is important to note that the specific requirements and design considerations of each residential tower project should be taken into account. Factors such as the height of the tower, load-bearing capacity, and architectural design may influence the suitability of steel formwork. Consulting with a structural engineer or construction professional is recommended to determine the most appropriate formwork system for a specific residential tower construction project.

Send your message to us

Tabel formwork system for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches