Shaft Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

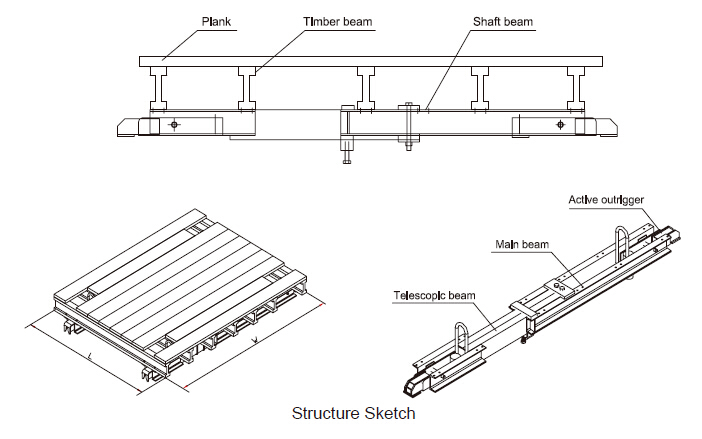

Shaft Platform

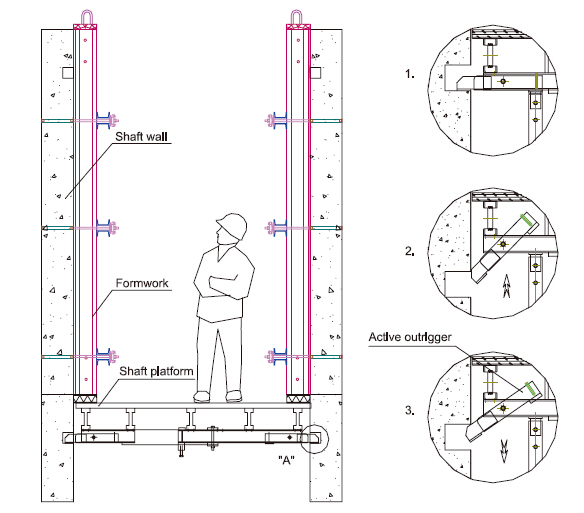

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

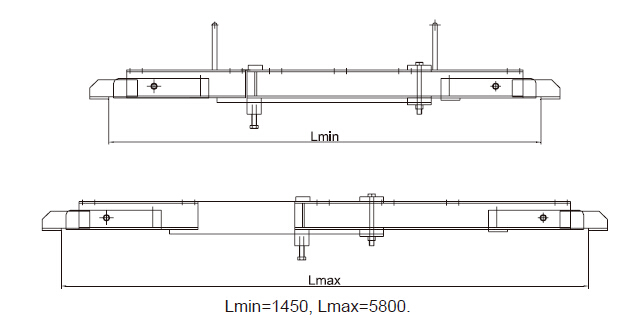

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: Can steel formwork be used for structures with high corrosion resistance requirements?

- No, steel formwork is not suitable for structures with high corrosion resistance requirements as steel is prone to corrosion.

- Q: How does steel formwork affect the schedule of concrete pouring?

- Steel formwork can have a significant impact on the schedule of concrete pouring. One of the major advantages of using steel formwork is its strength and durability, which allows for faster construction progress. Unlike traditional wooden formwork, steel formwork can be reused multiple times, leading to shorter construction cycles and faster completion times. The use of steel formwork also allows for a faster assembly and disassembly process. It requires less time to set up compared to wooden formwork, as it typically comes prefabricated or in standard sizes that can be easily assembled on site. This quick assembly process reduces the time needed for formwork installation, enabling concrete pouring to begin sooner. Additionally, steel formwork provides a smooth and uniform surface finish to the concrete. It eliminates the need for plastering or additional finishing work, saving time and effort. The smooth surface also reduces the curing time required for the concrete, as it allows for more efficient evaporation of moisture. Moreover, steel formwork is known for its superior strength and stability. This allows for a higher rate of concrete pouring, as it can withstand the pressure exerted by the wet concrete without deforming or collapsing. With steel formwork, larger concrete sections can be poured at once, reducing the number of pours required and consequently saving time. However, it is important to note that steel formwork requires careful planning and coordination to ensure a seamless workflow. The availability of steel formwork materials and equipment, as well as skilled labor, must be considered during the project scheduling process. Any delays in the procurement or fabrication of steel formwork can impact the concrete pouring schedule. In conclusion, steel formwork positively affects the schedule of concrete pouring by reducing construction time, providing a smooth surface finish, allowing for faster assembly and disassembly, and enabling larger concrete sections to be poured at once. However, proper planning and coordination are essential to maximize the benefits of steel formwork and avoid any potential delays.

- Q: Can steel formwork be used for both straight and curved structures?

- Yes, steel formwork can be used for both straight and curved structures. Steel formwork is versatile and can be easily shaped and adjusted to create various geometric shapes, including straight walls and columns as well as curved structures such as arches and curved walls. This flexibility allows for the creation of unique architectural designs and structures. Additionally, steel formwork has high strength and durability, making it suitable for use in both straight and curved structures.

- Q: What are the different types of access solutions available for steel formwork?

- There are several different types of access solutions available for steel formwork, depending on the specific requirements of the construction project. Some of the common access solutions include: 1. Ladder Access: This is the most basic and commonly used access solution for steel formwork. Ladders are attached to the formwork structure, allowing workers to climb up and down easily. Ladder access is simple, cost-effective, and suitable for low-rise structures. 2. Stair Access: For taller structures, stair access is a safer and more convenient option. Stairs can be attached to the steel formwork, providing a stable and secure pathway for workers to move between different levels. Stair access is particularly useful in high-rise buildings or projects with multiple levels. 3. Platform Access: Platforms are often used in conjunction with ladders or stairs to provide a wider working area. These platforms can be fixed or movable, allowing workers to access various parts of the steel formwork system easily. Platforms provide a stable and safe working surface, enhancing productivity and safety on the construction site. 4. Scaffold Access: Scaffold systems are commonly used for construction projects and can also be utilized for accessing steel formwork. Scaffold access provides a flexible and adjustable solution, allowing workers to reach different heights and areas of the formwork structure. Scaffold access is particularly useful for complex projects or projects with irregular shapes. 5. Crane Access: In some cases, large steel formwork panels or structures may require the use of cranes for access. Cranes can lift workers to the desired height, providing a quick and efficient access solution. Crane access is often used for heavy-duty formwork systems or projects with large-scale structures. In summary, the different types of access solutions available for steel formwork include ladder access, stair access, platform access, scaffold access, and crane access. The choice of access solution depends on factors such as the height and complexity of the structure, as well as the specific requirements of the construction project.

- Q: How does steel formwork contribute to the overall stability of a structure?

- The construction industry greatly relies on steel formwork to ensure the stability of structures. This crucial component is extensively used for casting concrete elements like walls, slabs, columns, and beams. Steel formwork enhances stability by providing a rigid and robust framework for pouring and setting concrete. The steel panels and frames are designed to withstand the pressure exerted by wet concrete, preventing deformation during the curing process. This prevents any potential structural deficiencies or unevenness that may compromise stability. Moreover, steel formwork offers exceptional strength and durability, making it suitable for various construction projects. Its high tensile strength enables it to bear heavy loads, which is especially important for large-scale structures. Additionally, the formwork's strength allows for multiple reuses, reducing construction costs and environmental impact. Furthermore, steel formwork ensures excellent dimensional stability, maintaining its shape and dimensions throughout the construction process. This characteristic is crucial for structural accuracy and consistency. Additionally, steel formwork is highly resistant to moisture and other environmental factors that can affect stability. Its corrosion-resistant properties make it suitable for outdoor construction sites exposed to rain, humidity, and other elements. This resistance to corrosion ensures the formwork's integrity over time, contributing to the long-term stability of the structure. In conclusion, steel formwork plays a vital role in enhancing the stability of structures. Its rigid and robust framework, combined with its strength, durability, dimensional stability, and resistance to environmental factors, ensures proper concrete formation and structural integrity. By providing a stable foundation for the construction process, steel formwork significantly contributes to the stability and safety of the final structure.

- Q: How long does it take to set up steel formwork?

- The time required to set up steel formwork varies depending on several factors. These factors include the complexity of the structure, the level of experience and skill of the workers, the size of the project, and the availability of equipment. In general, the setup of steel formwork can take anywhere from a few hours to several days. For smaller projects with simple structures, a team of experienced workers can usually complete the formwork setup within a day or two. This involves tasks like measuring and marking the layout, assembling the steel panels, beams, and props, and securing them in place. Additionally, braces and ties may be attached to ensure stability and alignment. On the other hand, larger and more intricate projects may require more time for formwork setup. These projects may include complex designs, multiple levels or floors, and a greater number of formwork components. In such cases, the setup process may take several days or even weeks, depending on the size of the team and the availability of resources. It is worth noting that although steel formwork may take longer to set up compared to other types of formwork like timber or plastic, it offers advantages such as durability, reusability, and enhanced stability. These benefits outweigh the additional time required for setup, particularly for large-scale construction projects that necessitate robust and dependable formwork systems.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers durability and strength, making it suitable for creating precise and complex shapes required for precast concrete columns. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for precast concrete column production.

- Q: Can steel formwork be used for water retaining structures?

- Water retaining structures can indeed utilize steel formwork. One of the notable characteristics of steel formwork is its strength, durability, and ability to withstand high pressures. When designed and constructed correctly, steel formwork can establish a watertight seal and effectively resist the hydrostatic pressure exerted by water. Moreover, steel formwork facilitates a uniform and smooth finish, minimizing the chances of water leakage. However, it is crucial to implement appropriate waterproofing measures, including the use of suitable sealing materials and techniques, to prevent potential water leakage or seepage through joints or connections. Consistent inspection and maintenance are also indispensable to ensure the long-term integrity of the water retaining structure.

- Q: How does steel formwork handle concrete vibration and air entrapment?

- Steel formwork is widely recognized for its effectiveness in managing concrete vibration and reducing air entrapment during pouring and curing. To begin with, the strength and rigidity of steel formwork make it capable of withstanding the intense vibrations caused by compacting concrete. When poured into steel formwork, the formwork acts as a barrier, preventing excessive movement or deformation that could lead to the creation of voids or air pockets. This ensures that the concrete is evenly distributed and compacted throughout the structure. Moreover, steel formwork is designed with tight joints and smooth surfaces, which aids in minimizing air entrapment. The joints are securely sealed to prevent any leakage that could result in air getting trapped within the concrete. This is particularly crucial as air pockets have the potential to weaken the structural integrity and durability of the concrete. The smooth surfaces also facilitate the smooth flow and consolidation of the concrete, reducing the likelihood of air entrapment. Additionally, steel formwork can be easily customized and adjusted to meet the specific requirements of the construction project. This allows for precise and accurate placement of the formwork, ensuring that the concrete is poured and compacted in the desired manner. By maintaining complete control over the formwork, the risk of air entrapment can be minimized, resulting in a more durable and reliable concrete structure. In conclusion, steel formwork is an excellent choice for managing concrete vibration and air entrapment. Its strength, rigidity, tight joints, and smooth surfaces provide the necessary stability and control during the pouring and compacting process. By utilizing steel formwork, construction professionals can guarantee that the concrete is properly consolidated and free from air pockets, leading to a high-quality and long-lasting structure.

- Q: How does steel formwork handle different concrete testing procedures?

- Steel formwork is a popular choice in the construction industry due to its durability and versatility. When it comes to handling different concrete testing procedures, steel formwork is highly capable and efficient. Firstly, steel formwork can withstand the pressure and weight exerted by concrete during different testing procedures. Whether it is a compression test, slump test, or any other form of concrete testing, the robustness of steel formwork ensures that it remains intact and does not deform under the load. Secondly, steel formwork provides a smooth and even surface for concrete testing. This is crucial for accurate test results, as any irregularities or inconsistencies in the formwork can affect the quality and integrity of the concrete sample being tested. Steel formwork is known for its precision, ensuring that the concrete is poured and shaped precisely as required for each specific testing procedure. Moreover, steel formwork is adaptable and can be easily modified to accommodate various concrete testing procedures. It can be adjusted or reconfigured to meet the specific requirements of different tests, such as creating different shapes, sizes, or depths for concrete samples. This flexibility allows for efficient and accurate testing, as the formwork can be customized according to the testing procedure being carried out. Additionally, steel formwork is reusable, which offers cost-effectiveness and sustainability in concrete testing. Unlike other types of formwork that may need to be discarded after a single use, steel formwork can be dismantled, cleaned, and reused multiple times. This reduces the overall expenses associated with concrete testing procedures and minimizes waste generation, making it an environmentally friendly option. Overall, steel formwork is well-suited to handle different concrete testing procedures due to its strength, precision, adaptability, and reusability. It provides a stable and consistent surface for accurate testing, ensuring reliable results. With its numerous advantages, steel formwork remains a preferred choice in the construction industry for various concrete testing requirements.

Send your message to us

Shaft Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords