Drywall Ceiling Grid - Suspension Ceiling Grid Plane System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

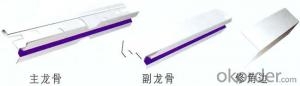

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

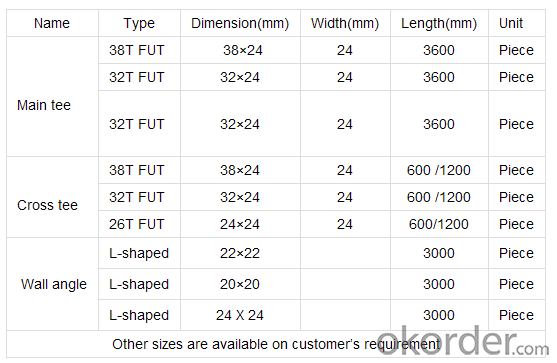

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: I see someone with a special tool to cut the keel, but do not know what is the name, it is difficult to find online, I would like to ask you know? Description: shape similar to the guillotine, put the keel, a force will be a light steel keel cut off.

- Automatic chase cut

- Q: Light steel keel how many meters long?

- 10 cm, 4 meters also have

- Q: i just leased a unit in a new plaza. im going to put a barbershop in it. what i want to do is to remove the suspended grid ceiling so it can make the shop look bigger. i know their is sometype of requirement for the ac and i cant just leave it out in the open.. what do i need to do to meet the requirements? ive seen that they put some type of cover over it..

- Exposed commercial HVAC has different requirements than regularly installed ducting. Most of it has to do with ridged ducting, proper insulation so that the tubes do not collect water vapor and cause a drip that people slip on. Best to check with your local permits and building codes office for anything particular to your area. If you remove something against code, you could be fined, shutdown till it is fixed or have your Certificate of occupancy revoked.

- Q: I am doing a ceiling tile for my English class. I have 2 differnet background options I want to do. It doesn't matter what background I choose I will put my name and 2013 on it. 1. Just do the whole background with blue glitter 2. Do a texas flag in glitter

- If it the type of tile you can take down from a grid, take it down and outside and use spray paint. If you are handy with masking tape, you can put the design on after you paint the background first.

- Q: For example, T-keel ah, triangular keel ah, aluminum keel ah, etc., belong to the paint keel it

- You said the keel is used to do the ceiling, aluminum keel and paint keel is divided by material, aluminum surface oxide film protection, no paint, paint keel is in the ordinary metal keel surface to increase the paint protective layer, Paint keel, in the installation of anti-rust paint and a variety of colors when the finish; and T-keel triangle keel, is the ceiling keel section shape, different from the ceiling type, and some ceiling installation can be seen after the completion of Keel (T-type), and some ceiling installation can not see the keel (triangle).

- Q: Can the hotel light steel keel wall be used with plastic threading pipe?

- Hotel noise is a lot of customers pay attention to the point, now people pay attention to privacy and security, you want to run a good hotel is still a good sound insulation.

- Q: It is good when the ceiling is light steel keel and wood keel

- In fact, the development of the ceiling process to the present, is not purely with wooden keel or light steel keel, and these two years have seen a lot of the combination of the way the ceiling. Wood keel easy to do modeling, light steel keel support strong, not easy to deformation, so now when the ceiling, in the need to shape the place with wooden keel, the other to do with the support of light steel keel is the most reasonable way.

- Q: Light steel keel ceiling when to add crossed keel

- Two gypsum boards overlap with keel

- Q: What is the paint keel

- It is clear that the aluminum alloy keel, because the aluminum keel after treatment, paint is not bleaching, no rust, no discoloration, corrosion resistance, erosion resistance, even for the outdoor corridor ceiling, there is no quality problems. And paint keel, paint keel its raw material is iron, easy to rust, change, Diaoqi, a long time the problem has all appeared, especially can not be used in wet places, so the general bathroom are used aluminum alloy keel as And silicon calcium board supporting. Because the aluminum keel can be waterproof and moisture. But the only point is that you can not deny the advantage of the paint keel! The price of the paint keel is cheaper than that of the aluminum keel, which is between 6 and 12 per square, while the price of the aluminum keel is between 6.5 and 15, and the advantage is that The

- Q: How many thickness of the light steel keel to do the wall?

- Can be used 12mm single gypsum board + 75mm steel keel (filled with 50mm thick rock wool) +12 mm single layer of gypsum board plus rock wool is mainly for the insulation

Send your message to us

Drywall Ceiling Grid - Suspension Ceiling Grid Plane System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords