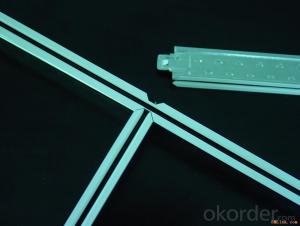

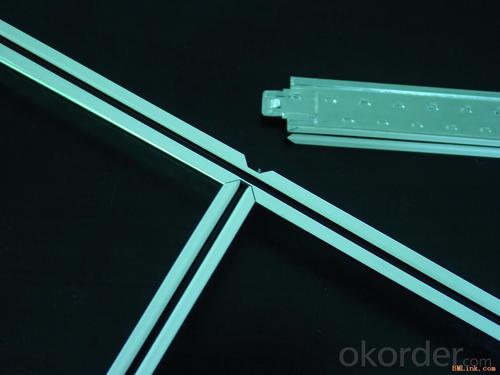

Ceiling Tee Grid for Suspension System New Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Selection Attributes

Rotary-stitched during manufacture by a patented method for additional torsinal strength and extra stability during installation; maintains size and shape of reverl when cutting perimetre tees.

Choice of black and white reveal.

Peakform® patented profile increases strength and stability for improved performance during installation.

XL staked-on end detail provides secure loked connection.

The performance of the VisionBM Ceiling Tee Grid Suspension System is based on the specific combination of components and method of installation. Other manufacturer's components and installation methods were not tested and are not covered in this evaluation.

To provide an unrestrained ceiling system that will accommodate the movement of the structure during a seismice event and the objective is to have a free-floating ceiling.

Feature (Main T cross T Fineline ceiling Tee bar 38 height)

1.Elegant

2.High strength/Rust resistant

3.Fire Proof, Nice quality

4.Made of galvanized steel and Al-alloyAcid & Alkali resistant

- Q: I feel the self-tapping screws do not drill into the light steel keel Hand drill use method is not directly to the back of the tapping screw inserted into the drill drill and then fixed on the light steel keel ah?

- Gypsum board with the screw is not an ordinary self-tapping screws, its name is "dry wall nail", its structure and material and ordinary tapping screws are different, hardness, small diameter, long teeth, these features are easy It is easier to drill into hard objects. Although the light steel keel is steel, but the wall thickness is limited, the use of hand drill or wind can be easily approved by dry wall nails drill through it. On the dry wall nails to use a special batch of head, also known as the cross head, hand drill to use it to dry wall nails.

- Q: Light steel keel how fixed in the external walls?

- With light steel keel partition and light steel keel fixed on the external wall is completely different from the two practices ah To make it clear

- Q: Light steel keel mark which category

- What is the world keel and light steel keel? What is the use of ah?

- Q: We have a drop ceiling but rather large holes for the many light fixtures (at least 20, like a grid of light bulbs as decoration) in our basement. The holes are about 2 inches in diameter and the light bulb doesn't fill up the holes completely. Is it safe to live down here without removing the insulation?

- Jeff answered the technically question quite clearly. As far as being able to live in the basement with the fiberglass insulation, yes you can. It won't shed any material unless it's disturbed. Ensure there is no moisture in the insulation as this would lead to further issues...mold ETC, but as long as it is in sound condition and not disturbed regularly it will be fine to live in the basement.

- Q: We have a house (built in 1918) that has large ceiling beams in both the living and dining room. This wood trim goes along the edge of the wall and then across the ceiling (in a grid in the dinning room). Unfortunately the previous owners painted them a dark brown (to look like a dark stain I imagine) but it is bad. All the wood work is a dark mahogany like stain and although there are many windows, it is very dark. We are repainting everything! Where can I find pictures of different color combinations for ceilings with painted beams? I really need help visualizing how it will look in a few different ways to decide.Thank you for the help!

- Painted Ceiling Beams

- Q: how do you level ceiling grid for acoustic ceilings?

- Their are a couple of ways to level the grid. One is to buy a laser that shoots a level beam that you can measure from. Another is to use a plastic milk jug with a 3/8 clear flexible tube attached to the side near the bottom. Fill the jug 3/4 full of water. Unscrew the cap on the jug. Buy enough 3/8 tubing so that it will reach the entire room from one central spot. Hold the tube up to the wall, wait for the water to settle, and make a mark. Continue this until all marks are created. You may want to buy some blue or green food coloring to see the water line better.

- Q: I'm doing a reno in my basement and want to put crown molding up but can't imagine it looking good. Any suggestions?

- It would look absurd on a drop ceiling (metal grid and removable tiles). You wouldn't use any molding at all on such a ceiling.

- Q: Light steel keel use method

- This is the floor or roof pavement used to facilitate the decoration and lifting the structure of other equipment

- Q: Is it nice to use a light steel keel or a wooden keel?

- Certainly is light steel keel is good, fire is not easy to deformation shortcomings is no way to do modeling, such as profiled ceiling wood keel can do the cost of the opposite is relatively high

- Q: Im looking to put one up in an area that is 20x22.... does any one know a round about price?

- The grid work will run about $.90 per square foot and the tile from $.60 to $1.60 or more.Good Luck

Send your message to us

Ceiling Tee Grid for Suspension System New Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords