T Bar Suspended Ceiling Grid System - Main and Cross Tee with Wall Angle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

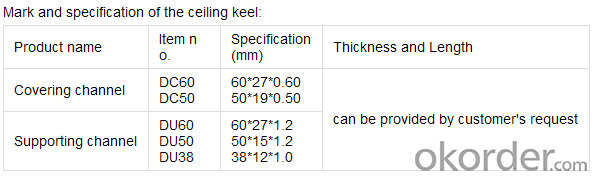

Product Specifications:

Image

- Q: Prepare the ceiling, want to know how to use light steel keel is long, such as a light steel keel is 3 meters long, and my room is 4.8 meters long, that keel is how to pick up to ensure the length of the Can I guarantee strength?

- Strength is no problem. When the keel is lengthened, pay attention to it, do not put the increase into the above or put the following, to stagger. For example, the extension of a root in the top, then it is next to the two long extension in the bottom. But also to consider the same wall of the keel through the heart to a high degree of consistency.

- Q: I am trying to hang a 30 LBS item from a drop ceiling, with no luck. I would like to use 2-3 eyebolts to distribute the weight, but everytime I think I figured it out, it pulls right through. The ceiling can't be very thick at all. Can this be done?

- You won't be able to hang from the grid. What you can do is to get some threaded rod and rod anchors, attach them to the framing above the grid, and then drill a small hole in the tile for the rod to come through for the object you wish to hang. Hope this helps.

- Q: What is light steel keel arch? Under what circumstances need to be arch?

- We often take measures in the middle to lift it up a little, so that it is affected by the heavy sag of gravity, which is the legendary arch.

- Q: Construction Process of Light Steel Longguard Paving

- Construction points (1) according to the design of the ceiling height on the wall line, the level of tolerance ± 5 mm. (2) boom installation 1) choice of boom. Generally speaking, light steel keel ceiling selection of the boom can be based on the standard map, light steel ceiling selection diameter 6, medium, heavy selection of diameter 8. If the design has special requirements, the load is large, you need to be determined by structural design and verification. 2) According to the design or standard map to determine the hanging point spacing. Generally not on the ceiling between the 1200 ~ 1500 mm, the ceiling distance of 900 ~ 1200 mm. 3) fixed ceiling. For the cast-in-place concrete roof can be embedded in the construction of embedded boom or embedded iron, so that the boom and iron welding. In the old building or concrete orifice can be used under the nail gun hanging point iron (small angle iron) fixed, need to add a gasket. The nail must be secure (if the nail is perforated, the boom can be used to fix the boom). Or the expansion bolt under the lifting point. 4) When the boom is installed, the upper end should be welded with the embedded piece, the lower end should be set with thread, with a good nut, the end of the thread exposed to not less than 3MM.

- Q: Known floor building elevation, ceiling elevation, light steel keel gypsum board ceiling boom length how to calculate?

- Depends on the height of the room and the spacing of the boom

- Q: This is one of the new low-profile ones that hangs only 1 1/8 below the joists. The main drain PVC pipes all run together at one point next to the foundation (poured, not block) wall. There is about a 5-6' section wide that all hangs about 4-5 below the joist and sticks out 4-5 from the wall. Question is, how do I go about putting the drop ceiling around this mess? Do I build a case for it and block it all in with nice cedar stained wood? I need some suggestions please!

- i would really need to see this for an honest answer. my only suggestion would be to block it all in with cedar like you said, but rather than just blocking it in, why not make a cabinet that is the same measurements as what you would need to block off the eyesore and run it the whole length off the wall or ceiling. this way you would have a long, narrow, and wide cabinet and it wouldnt look like you just covered it up it would also have a functioning purpose.this would be especially useful, if you have children, to keep harmful things out of their grasp.

- Q: What is the meaning of H38 light steel keel on construction?

- Light steel keel height of 38 mm

- Q: Light steel keel paper gypsum board wall at the bottom of whether to concrete guide wall

- If you need moisture, it will use

- Q: I would like to hang curtains from the ceiling to function like a room divider. But I can't make any holes in the ceiling, so does anyone know how I could do this? Or any alternatives to using some fabric as a room dividerThanks in advanced

- A okorder /... There are lots of other sites that may have simpler directions. LOL

- Q: We are working on a store front which has ceiling tiles in it. However we wanted an open air look, maybe leaving the grids, but no tiles. We were going to paint the grids and tiles, but have discovered that it would be too expensive, because we would have to paint them back before moving. My question would be, above the tiles is just a metal roof, which is a flat roof, so it would have the tar on top of the metal I think, is it a good idea to just remove the tiles for the open air look? or would that make the building too inefficient during the winter and summer?

- It will make it colder. Warm air travels upward & you would have no ceiling to stop that escaping heat. Ceiling tiles. We had some that looked awful. We took them down & layed them on the yard. Vacuumed them and with a paint brush, painted lightly (not in the 'dimples', cracks of tile) so the 'old' still showed in the 'dips', then replaced when dry.

Send your message to us

T Bar Suspended Ceiling Grid System - Main and Cross Tee with Wall Angle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords