Aluminum Sheets in Texas - Stucco and PE Painted Aluminum Coils for Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Stucco and PE Painted Aluminum coils Used for Decorations

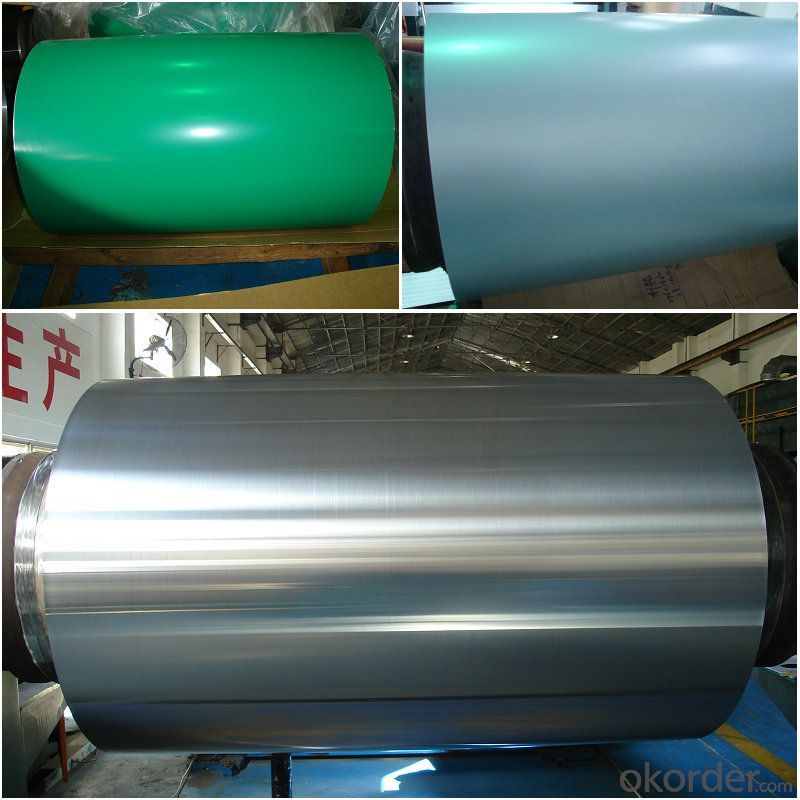

Our stucco painted aluminum coils are widely used in decorations, such as ice-box, cars, etc.

Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of Stucco and PE Painted Aluminum coils Used for Decorations

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

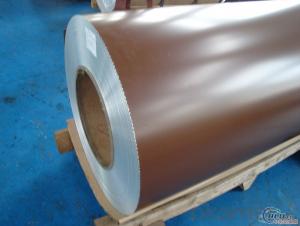

3. Stucco and PE Painted Aluminum coils Used for Decorations Images

4. Specification of Stucco and PE Painted Aluminum coils Used for Decorations

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The friction properties of an aluminum sheet are significantly affected by its surface roughness. When the surface is rough, there are more microscopic peaks and valleys, which can enhance the frictional forces between the sheet and the contacting surfaces. Generally, an increase in surface roughness results in a higher friction coefficient. This occurs because the roughness increases the effective contact area between the aluminum sheet and the opposing surface, leading to more interlocking and adhesion between the two surfaces. Consequently, the resistance to relative motion, or friction, is heightened. Moreover, a rough surface can trap lubricants or contaminants, reducing lubrication efficiency and increasing friction. The roughness of the aluminum sheet also influences the formation and retention of a lubricating film, further impacting the friction properties. It is important to acknowledge that the type of roughness, such as its amplitude, wavelength, and orientation, can also affect the friction properties. For instance, certain surface textures, like grooves or patterns, may facilitate lubricant retention and reduce friction, even with increased roughness. In summary, the friction properties of an aluminum sheet are significantly determined by its surface roughness. A rough surface increases the contact area and adhesion between the sheet and opposing surface, resulting in higher friction coefficients. However, the specific characteristics of the roughness and the presence of lubricants or contaminants can further influence the friction behavior.

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- If the thickness of the sheet is not enough, the effective thread stroke can be mounted with K nuts. Rivet nuts are required if accuracy is required.If it is a thick aluminum sheet, it can be directly drilled and tapped; also, the steel screw sleeve can be added.

- Q: To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- This Site Might Help You. RE: Can just aluminum be lifted by a magnet? Just a plain aluminum gutter nail for example? To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go...

- Q: What is the weight of a standard aluminum sheet?

- The weight of a standard aluminum sheet can vary depending on its thickness, dimensions, and grade. On average, a standard aluminum sheet weighs around 2.7 grams per cubic centimeter (g/cm³).

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Aluminum sheets can be obtained in various finishes, such as brushed or polished, providing different surface textures and appearances. These finishes are achieved by employing diverse processes that modify the aluminum sheets. Brushed finishes, for instance, create a textured pattern by delicately brushing the surface with fine abrasive materials, resulting in a satin-like look. Conversely, polished finishes involve utilizing abrasive compounds or polishing wheels to buff the surface to a high shine. Consequently, these distinct finishes enable the customization and versatile utilization of aluminum sheets across different industries.

- Q: This question asks about the distinctions between aluminum sheets that are produced domestically versus those that are imported.

- <p>Yes, there can be differences between domestic and imported aluminum sheets. These differences may include quality standards, material composition, thickness, surface finish, and price. Domestic sheets are often produced to meet local standards and regulations, while imported sheets may adhere to different international standards. The manufacturing process and raw materials used can also vary, leading to differences in durability, strength, and workability. Additionally, imported sheets might have different certifications or come from countries with lower production costs, which can affect the price. However, it's important to note that not all imported aluminum sheets are of lower quality; some may be of higher quality or have specific characteristics that are not available domestically.</p>

- Q: The user is asking if it's possible to substitute recycled aluminum sheets for new ones in a project or application.

- <p>Yes, you can use recycled aluminum sheets instead of new ones in many applications. Recycled aluminum maintains the same properties as new aluminum, making it suitable for construction, manufacturing, and various other uses. It's also more sustainable and cost-effective. However, it's important to ensure that the recycled aluminum meets the required specifications and quality standards for your specific project to avoid any structural or performance issues.</p>

- Q: Can aluminum sheets be used for outdoor furniture?

- Yes, aluminum sheets can be used for outdoor furniture. Aluminum is a popular choice for outdoor furniture due to its durability, lightweight nature, and resistance to rust and corrosion. It is commonly used to make outdoor tables, chairs, and other furniture pieces.

- Q: This question asks for a list of various types of aluminum profiles that are typically used in conjunction with aluminum sheets.

- <p>Aluminum profiles are extruded shapes commonly used with aluminum sheets for various applications. The different types include: 1. Angle profiles, which are used for corners and edges. 2. Channel profiles, suitable for creating channels or frames. 3. T-slot profiles, ideal for modular systems requiring adjustable components. 4. U-channel profiles, used for covering edges and creating frames. 5. H-profiles, often used in structural applications. 6. Flat bar profiles, used for simple straight edges. 7. Round and square tube profiles, used for structural support and design elements. 8. Special profiles, which are custom-made for specific applications. These profiles are chosen based on the structural needs and design requirements of the project.</p>

- Q: Can the aluminum sheets be used for manufacturing aircraft landing gears?

- Yes, aluminum sheets can be used for manufacturing aircraft landing gears. Aluminum is commonly used in the aerospace industry due to its lightweight yet strong properties, making it suitable for such critical components like landing gears.

Send your message to us

Aluminum Sheets in Texas - Stucco and PE Painted Aluminum Coils for Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords