Aluminum Metal Sheets for Polyester Coated Decoration Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

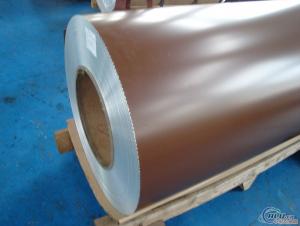

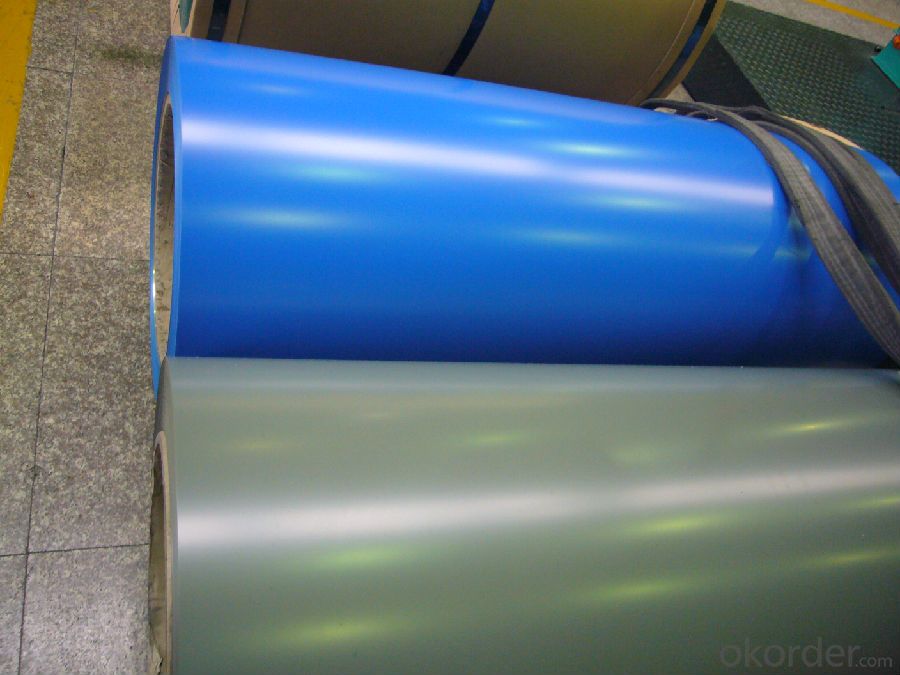

1.Structure of Aluminium Coils for Polyester Coating Decoration

Aluminium Coils for Polyester Coating Decoration are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Polyester Coating Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Polyester Coating Decoration

4. Product Specification of Aluminium Coils for Polyester Coating Decoration

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ of Aluminium Coils for Polyester Coating Decoration

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for bus shelters?

- Indeed, bus shelters can utilize aluminum sheets. Aluminum, a lightweight and enduring substance, finds extensive use in construction ventures, encompassing bus shelters. Its exceptional resistance to corrosion renders it apt for outdoor scenarios, where it confronts inclement weather. Moreover, aluminum sheets are conveniently malleable and can be fashioned into manifold forms and dimensions, permitting tailor-made designs and effortless installation. Employing aluminum sheets for bus shelters also entails a cost-efficient resolution as it demands scant upkeep and boasts a prolonged existence.

- Q: How does the surface cleanliness of aluminum sheet affect its adhesion properties?

- The adhesion properties of aluminum sheet are significantly influenced by its surface cleanliness. Contaminants, such as dirt, grease, or oxide layers, can impede the effectiveness of adhesive bonding with the aluminum sheet. To achieve strong adhesive bonds, it is essential to have a clean and well-prepared surface. When the aluminum sheet is free from contaminants, the adhesive can evenly spread and intimately connect with the surface, resulting in a stronger bond. Conversely, if the surface is not clean, the adhesive may struggle to adhere properly, leading to weak or unreliable bonds. In addition to contaminants, the presence of oxide layers on the aluminum surface can also impact adhesion properties. Aluminum naturally forms an oxide layer when exposed to air, which can hinder adhesive bonding. It is necessary to remove or modify this oxide layer to ensure good adhesion. Surface preparation methods, such as cleaning, degreasing, and treating with chemical solutions, can help eliminate or alter the oxide layer, thereby allowing for better adhesion. Various techniques can be employed to improve the cleanliness and adhesion properties of aluminum sheets. These include mechanical cleaning methods such as abrasive cleaning or sanding, solvent cleaning, acid etching, or even plasma cleaning. The selection of each method depends on the type and extent of contamination present on the surface. In conclusion, the surface cleanliness of aluminum sheet directly impacts its adhesion properties. A clean and properly prepared surface promotes better adhesion by facilitating intimate contact between the adhesive and the aluminum sheet. Therefore, it is crucial to consider and address surface cleanliness when aiming for strong and reliable adhesive bonds with aluminum sheets.

- Q: Are aluminum sheets suitable for roofing systems?

- Indeed, aluminum sheets prove to be an appropriate option for roofing systems. The durability, lightweight composition, and corrosion resistance of aluminum render it a favored choice for rooftops. Moreover, aluminum possesses fire-resistant properties and can endure harsh weather conditions, including strong gusts and heavy precipitation. With their long lifespan and minimal upkeep requirements, aluminum roofing sheets present a financially sound choice over time. Furthermore, the highly reflective nature of aluminum aids in reducing energy expenses by maintaining cooler indoor temperatures in hot climates. In summary, aluminum sheets emerge as a dependable and effective preference for roofing systems.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- Steel Vs Alloy Wheels

- Q: Can aluminum sheets be used for signage purposes?

- Yes, aluminum sheets can be used for signage purposes. They are commonly chosen for outdoor signs due to their durability, weather resistance, and lightweight nature. Aluminum sheets can be easily customized, printed on, and shaped to create professional and long-lasting signage.

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- They felt that used to be the case because of the aluminum seeping into the food. Hard to find an uncoated aluminum pot now. You get more aluminum from deodorants and antacids than cookware. You shouldn't though cook or store tomatoes in aluminum...and that's just the reaction in chemistry.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces.

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- Personally I would go with the high quality Aluminum because it would be stiffer, but not nesaccarily lighter. A mediocre carbon frame are known to not take stress well and can break more easily than a high quality Aluminum. I would only go with Carbon if it was high quality.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- nah, it;s fine i have a 1999 GT al frame with 44000 miles ain;t dead or cracked yet carbon is the thing with the real horror stories Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing. --no, too much trouble for nothing wle

Send your message to us

Aluminum Metal Sheets for Polyester Coated Decoration Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords