Aluminum Sheets in Tennessee - Color Coated Aluminum Coils for Ceiling Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

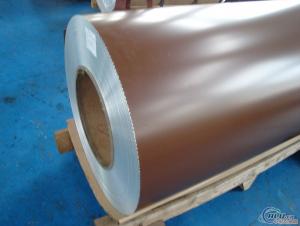

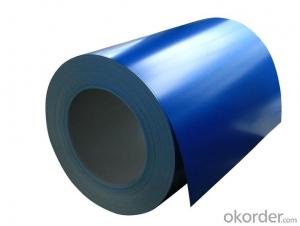

1.Structure of Color Coated Aluminium Coils for Ceiling Decoration

Color Coated Aluminium Coils for Ceiling Decoration is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA5052 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Ceiling Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Color Coated Aluminium Coils for Ceiling Decoration

4. Product Specification of Color Coated Aluminium Coils for Ceiling Decoration

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ of Color Coated Aluminium Coils for Ceiling Decoration

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: An aluminum engine block has a volume of 4.77 and a mass of 12.88 .

- Aluminum okorder /

- Q: i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- Aluminum is lousy for casting because it shrinks and tears. However you can add about 2% finely divided steel and get a useable alloy. It is better to use what everybody else uses: pot metal. Any junk yard can provide an endless supply of carburetor bodies which you can melt at fairly low temperatures and get nice strong castings. If you can locate some ancient floppy drives or dot matrix printers you will get a prettier alloy.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a durable and lightweight material that is resistant to corrosion and easy to clean, making it a popular choice for food preparation. However, it is important to note that aluminum can react with certain acidic or salty foods, so it is recommended to use a protective barrier such as parchment paper or silicone mats when working with such ingredients.

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The modulus of elasticity of aluminum sheets typically varies based on the alloy and temper. Nevertheless, an often utilized figure is approximately 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This figure denotes the material's stiffness or rigidity, revealing its capacity to endure deformation when subjected to stress. It is essential to acknowledge that diverse grades and conditions of aluminum might possess slightly distinct modulus of elasticity values. Hence, consulting the specific material specifications is advisable for precise information.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Yes, 101 aluminum sheets are generally easy to work with when it comes to cutting, drilling, and shaping. Aluminum is a lightweight and malleable material, making it relatively easy to manipulate using common tools. However, the specific ease of working with 101 aluminum sheets may vary depending on the thickness of the sheets and the specific tools and techniques used.

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- In general terms, you will get a smoother, quieter better ride from the fiberglass than the aluminum. The fiberglass is heavier and will ride a little deeper in the water. Obviuosly, the aluminum will bounce off rocks better than the glass, but we usually try to avoid those situations. Also, resale will most likely be better on the good glass boats.

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several methods of surface passivation for aluminum sheets, including anodizing, chromate conversion coating, and organic coatings. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Chromate conversion coating is a chemical treatment that converts the aluminum surface into a thin chromate film, providing corrosion resistance. Organic coatings, such as paints or lacquers, can also be applied to aluminum sheets to provide a protective barrier against moisture and other environmental elements.

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: What are the different grades of aluminum sheet?

- There are several different grades of aluminum sheet available in the market, each with its own unique properties and applications. Some common grades include: 1. 1100: This grade is known for its excellent corrosion resistance and high thermal conductivity. It is often used in chemical equipment, reflectors, heat exchangers, and electrical conductors. 2. 3003: This grade is alloyed with manganese, making it highly resistant to corrosion. It is commonly used in cooking utensils, storage tanks, and architectural trim. 3. 5052: This grade has good formability and high fatigue strength. It is often used in marine applications, such as boat hulls and components, as well as in aircraft fuel tanks and structural parts. 4. 6061: This grade is known for its excellent strength-to-weight ratio and good machinability. It is commonly used in automotive parts, bicycle frames, and structural components. 5. 7075: This grade has high strength and toughness, making it suitable for aerospace applications, such as aircraft wings and fuselage structures. Each grade of aluminum sheet has its own specific characteristics and is chosen based on the requirements of the particular application. It is important to consider factors such as corrosion resistance, strength, formability, and machinability when selecting the appropriate grade.

- Q: Are aluminum sheets suitable for HVAC applications?

- Yes, aluminum sheets are suitable for HVAC applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it ideal for use in heating, ventilation, and air conditioning systems. It offers excellent thermal conductivity, allowing for efficient heat transfer, and can be easily formed and fabricated to meet specific requirements in HVAC installations. Additionally, aluminum is also environmentally friendly as it can be recycled, making it a sustainable choice for HVAC applications.

Send your message to us

Aluminum Sheets in Tennessee - Color Coated Aluminum Coils for Ceiling Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords