Streamwood IL Aluminum Coil Anodizing - PE Coated Aluminium Coil for Curtain Wall AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

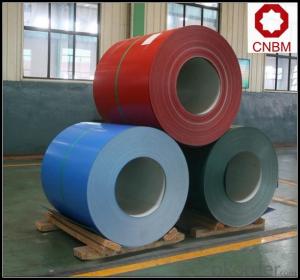

PE Coated aluminium coils are widly used in decoration field.Now we mainly exported to Asian countries and European countries.For the paint, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

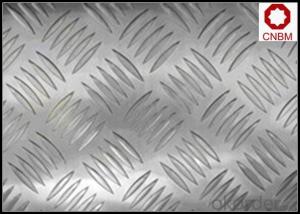

3.Image

4. Product Specification

| Alloy | Temper | Coating Thickness | Coil ID | Coil Weight |

| AA3003 | H14 | 22-25 MICRON | 505MM | 2.5 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 5 tons.

- Q: Is it safe and practical to use aluminum coils in cooking processes?

- <p>Aluminum coils can be used for cooking, but with certain precautions. They are commonly used in commercial kitchens for their heat conductivity and durability. However, for home cooking, it's important to avoid acidic or alkaline foods, as aluminum can react with them. Additionally, prolonged exposure to heat can cause aluminum to leach into food, which some studies suggest may have health implications. It's advisable to use aluminum cookware with a protective coating or opt for alternative materials like stainless steel or cast iron for health-conscious cooking.</p>

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- This Site Might Help You. RE: Composite vs Aluminum baseball bats? Which is better composite or aluminum, and what are some main differences between the two?

- Q: What are the common surface treatments for aluminum coils in the automotive industry?

- Aluminum coils in the automotive industry undergo various surface treatments to improve their performance and appearance. Some popular treatments include anodizing, painting, cladding, clear coating, and polishing/buffing. Anodizing is a widely used treatment that forms a protective oxide layer on the surface of the coils. This is achieved by immersing the coils in an electrolytic solution and applying an electric current. Anodizing enhances corrosion resistance, durability, and allows for dye or paint application. Painting is another option for aluminum coil treatment, providing both aesthetics and protection against environmental factors. Coils are coated with either solvent-based or powder paint, offering an appealing appearance and safeguarding against scratches and UV radiation. Cladding involves bonding a layer of aluminum alloy with different properties onto the coil's surface. This treatment is commonly employed to enhance strength, thermal conductivity, or corrosion resistance. Cladding methods can include hot rolling, cold rolling, or explosive bonding. Clear coating is often applied to aluminum coils to create a transparent protective layer. This coating prevents corrosion, oxidation, and discoloration, while preserving the natural metallic appearance. Polishing and buffing are surface treatments that aim to improve the smoothness and shine of aluminum coils. Imperfections, scratches, and oxidation are mechanically removed through grinding or polishing. These methods are often used for decorative purposes in high-end automotive applications. These are merely a few examples of the surface treatments available for aluminum coils in the automotive industry. The choice of treatment depends on factors such as desired appearance, performance requirements, and environmental conditions the coils will face.

- Q: Can aluminum coils be used in the production of electrical enclosures?

- Yes, aluminum coils can be used in the production of electrical enclosures. Aluminum is a popular choice for manufacturing electrical enclosures due to its excellent conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils allows for the production of seamless and sturdy enclosures, ensuring efficient heat dissipation and protection for electrical components. Additionally, aluminum coils can be easily molded and formed into various shapes and sizes, providing flexibility in design. Overall, the use of aluminum coils in the production of electrical enclosures is a reliable and cost-effective solution.

- Q: Can aluminum coils be used in high-vibration environments?

- Yes, aluminum coils can be used in high-vibration environments. Aluminum is a lightweight and flexible material that can withstand and absorb vibrations effectively. It is commonly used in various industries, including automotive and aerospace, where high-vibration environments are prevalent. Additionally, aluminum coils are often designed and manufactured to have enhanced durability and resistance to vibration-related issues such as fatigue and cracking.

- Q: How do aluminum coils compare to copper coils?

- Coils made of aluminum and copper are commonly used in various applications, including heating, ventilation, and air conditioning (HVAC) systems. While aluminum and copper have their own advantages and disadvantages, there are notable distinctions between the two types of coils. First and foremost, cost is a significant factor. Generally speaking, aluminum is cheaper than copper, making it a more cost-effective option for specific applications. However, it is important to acknowledge that the cost of copper has decreased in recent years, resulting in a narrower price difference between the two materials. Another distinguishing feature is heat transfer efficiency. Copper is a better conductor of heat compared to aluminum, which means that copper coils have superior heat transfer capabilities. This leads to more efficient cooling or heating, resulting in lower energy consumption and potentially reduced operating costs. Conversely, aluminum coils have a higher thermal expansion rate, which can cause increased stress on the system over time. Durability is another aspect to consider. Copper is renowned for its durability and resistance to corrosion, making copper coils more reliable and long-lasting. On the contrary, aluminum is more susceptible to corrosion, particularly in areas with high humidity or exposure to saltwater. Nevertheless, advancements in coating technologies have enhanced the corrosion resistance of aluminum coils, making them suitable for numerous applications. Lastly, the weight of the coils is worth mentioning. Aluminum coils are significantly lighter than copper coils, making them easier to handle and install. This can be advantageous in situations where weight is a concern, such as in mobile or portable HVAC units. In conclusion, aluminum coils and copper coils possess their own distinctive characteristics and advantages. Aluminum coils are generally more cost-effective and lighter, but may have lower heat transfer efficiency and be more susceptible to corrosion. Copper coils, on the other hand, offer superior heat transfer, improved durability, and resistance to corrosion. The choice between the two materials ultimately depends on the specific requirements and priorities of the application.

- Q: What are the density and specific gravity values of aluminum coils?

- The density of aluminum coils is approximately 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³). The specific gravity of aluminum coils is approximately 2.7.

- Q: having trouble looking for tis information, don't know where to look.Is aluminum accessible to everyone?? Does it cost a lot, is it in minimal areas if so is it hard to transport to all around the world??

- I can't understand you question.do you mean how aluminum works?

- Q: Is there any elements that can be added to aluminum to create any compound?

- Which industries? while you're actually not greater particular the checklist can pass on perpetually. i'm going to checklist some nonetheless: Hydrogen-Used to make ammonia and for hydrogenation techniques like the production of liquid fuels and margarine. Ammonia-Used to make fertilizer for agriculture. Sulfuric acid-fabric ending, prescribed drugs, pesticides, oil-nicely acidification, preserving coatings, purification of petrol, manufacture of detergents, explosives....... Carbon-Used for all smelting of metals Iron-For the production of steel. Oxygen-Steelmaking, paint pigment, welding, rocket gas. As you may locate the checklist is getting ridiculous. Sulfuric acid is the main used yet you may look this info up in any good inorganic chemistry textbook.

- Q: What is the role of aluminum coils in the construction of aircraft?

- The significance and versatility of aluminum coils in aircraft construction cannot be overstated. Aluminum, with its exceptional properties like lightweightness, durability, and resistance to corrosion, is the preferred material for manufacturing aircraft. In particular, aluminum coils find extensive use in various aircraft components such as the fuselage, wings, and structural elements. One of the primary functions of aluminum coils is to impart structural strength while keeping the aircraft lightweight. By incorporating aluminum coils, aircraft manufacturers can effectively reduce the overall weight of the aircraft, leading to improved fuel efficiency and increased payload capacity. This holds immense importance in aviation, where even the slightest reduction in weight can have a substantial impact on performance and operational costs. Furthermore, aluminum coils play a pivotal role in enhancing the aerodynamic design of the aircraft. These coils are employed to shape the wings and other aerodynamic surfaces, enabling superior airflow and decreased drag. The flexibility of aluminum coils empowers engineers to create intricate, curved shapes that optimize the aircraft's aerodynamic performance, resulting in enhanced maneuverability and reduced fuel consumption. Another critical aspect of aluminum coils in aircraft construction is their ability to resist corrosion. Aluminum naturally forms a protective oxide layer when exposed to air, rendering it highly resistant to corrosion. This property proves indispensable in ensuring the aircraft's longevity and structural integrity, especially when subjected to harsh environmental conditions like high altitudes or coastal regions. Moreover, aluminum coils find application in the manufacturing of heat exchangers, crucial components of the aircraft's cooling and ventilation systems. These coils efficiently transfer heat either to or from the air, depending on the requirements of the system, enabling effective temperature control within the aircraft's cabin and engine compartments. In conclusion, the role of aluminum coils in aircraft construction is indispensible. They provide structural strength, contribute to aerodynamic efficiency, offer corrosion resistance, and facilitate efficient heat exchange. The utilization of aluminum coils enables the development of high-performance, reliable, and fuel-efficient aircraft that are essential for modern aviation.

Send your message to us

Streamwood IL Aluminum Coil Anodizing - PE Coated Aluminium Coil for Curtain Wall AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords