Decorative Aluminum Coil for Producing ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Plain Aluminium Coils Used for Producing ACP

Plain aluminium coils used for producing ACP are good at ductility, heat conductivity, anti-corrosion and moisture resistance.

They are widely used as base coils to produce ACP after being coated. Normal specification is 3003, H16, etc.

2.Main Features of Plain Aluminium Coils Used for Producing ACP

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

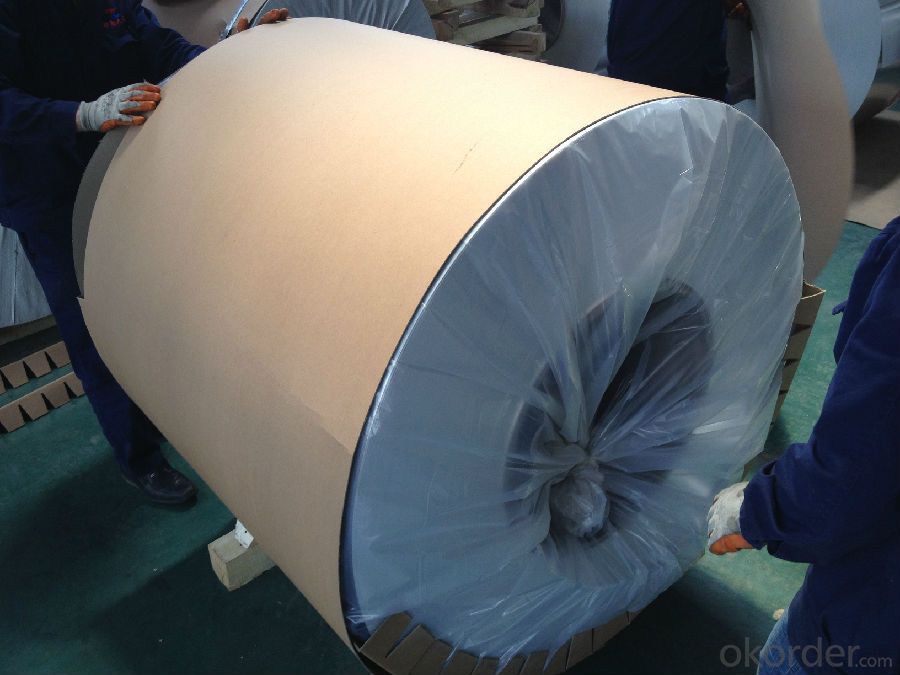

3. Plain Aluminium Coils Used for Producing ACP Images

4.Specification of Plain Aluminium Coils Used for Producing ACP

Alloy: AA3003, AA3105, etc

Temper: H16, H26, etc

Thickness: 0.3-1mm

Width:1000mm- 1500mm

Standard: GB/T3880-2006, ASTM, ISO, EU standard

5.FAQ of Plain Aluminium Coils Used for Producing ACP

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the maximum coil weight for aluminum coils?

- The maximum weight of aluminum coils can differ due to several factors including coil thickness, width, and the specific alloy employed. Typically, the maximum weight for aluminum coils falls within the range of 5,000 to 25,000 pounds. Nevertheless, it is crucial to acknowledge that these figures are only approximate and may vary based on the manufacturer's guidelines and the capabilities of the equipment. Moreover, it is advisable to consult the manufacturer or supplier in order to ascertain the specific limitations on coil weight to guarantee safe handling and transportation.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for packaging in the pharmaceutical industry due to its excellent barrier properties, light weight, and resistance to corrosion. It provides a protective and hygienic environment for pharmaceutical products, ensuring their safety and extending their shelf life.

- Q: Can aluminum coils be used in aerospace heat exchangers?

- Yes, aluminum coils can be used in aerospace heat exchangers. Aluminum is widely used in aerospace applications due to its lightweight and excellent heat transfer properties. It offers good corrosion resistance, high thermal conductivity, and is cost-effective, making it a suitable material for heat exchangers used in aircraft and other aerospace systems.

- Q: where is aluminum found in the world or in the universe?do u think aluminum is more valuable to people than gold?why or why not?im just lazy to look up the answers and person 4 best answer 10points

- where is aluminum found in the world aluminum is in fact the third most common element in the Earth's crust, and it is the most common metallic element on Earth. In a pure form, aluminum is silvery white and extremely lightweight. aluminum is more valuable to people than gold? aluminum continues to remake the modern world. We can see it everywhere; in architecture, transportation, electrical cables, communications and consumer products. Because it’s light-weight, strong, versatile and easy to recycle, aluminum is becoming more and more valuable in our daily lives melting point and boiling point Melting Point: 933.437 K (660.323°C or 1220.581°F) Boiling Point: 2792 K (2519°C or 4566°F)

- Q: What are the potential applications of colored aluminum coils?

- The possible uses for colored aluminum coils are extensive and varied, spanning across a multitude of industries. In the realm of construction, these coils serve both practical and aesthetic functions. Whether utilized as roofing material, siding, or ornamental features on structures, they offer protection against the elements while simultaneously enhancing visual appeal. In the automotive industry, colored aluminum coils find application in the creation of car body panels. The material's vibrant hues and durability make it an appealing choice for crafting stylish and long-lasting exteriors for vehicles. Additionally, the electronics and electrical industries benefit from the use of colored aluminum coils. They serve as casings for electronic devices, such as smartphones, tablets, and laptops, lending a visually pleasing touch to these gadgets. Furthermore, due to aluminum's lightweight nature, it is well-suited for heat sinks and other cooling components in electronic devices. The packaging industry can also take advantage of colored aluminum coils to produce captivating packaging materials for various products. The vibrant colors and sleek appearance of aluminum can enhance the visual allure of consumer goods, attracting potential buyers. Moreover, the furniture industry can employ colored aluminum coils to fashion contemporary and stylish furniture pieces. Aluminum's versatility allows for the creation of unique designs and shapes, adding a modern touch to interior spaces. Lastly, the signage and advertising industry can benefit from colored aluminum coils. They can be utilized to create custom signage, billboards, and promotional displays with vivid and long-lasting colors, serving as effective marketing tools. In summary, colored aluminum coils have an array of potential applications in industries such as construction, automotive, electronics, packaging, furniture, signage, and advertising. Their durability, lightweight nature, and aesthetic appeal make them a versatile material for a wide range of purposes.

- Q: How are aluminum coils different from other types of metal coils?

- Aluminum coils differ from other types of metal coils in several ways. Firstly, aluminum is a lightweight metal, making aluminum coils much lighter compared to coils made from other metals such as steel or copper. This lightweight property of aluminum makes it a popular choice for various industries where weight is a critical factor, such as aerospace and automotive industries. Secondly, aluminum coils have excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to air, preventing further corrosion. This resistance to corrosion makes aluminum coils suitable for applications in humid and corrosive environments, such as marine or coastal areas. Additionally, aluminum coils possess high thermal conductivity. This means that aluminum can efficiently conduct heat, making it an ideal material for heat transfer applications like HVAC systems, refrigeration units, and radiators. The high thermal conductivity of aluminum coils allows for more efficient cooling or heating processes. Furthermore, aluminum is highly malleable and ductile, which means it can be easily shaped and formed without losing its structural integrity. This malleability makes aluminum coils flexible and versatile, allowing them to be manufactured into various shapes and sizes to meet specific industry requirements. Lastly, aluminum is a highly sustainable and recyclable material. It can be recycled repeatedly without losing its quality or performance, making aluminum coils an environmentally friendly choice. This recyclability factor contributes to reducing the environmental impact and promoting a circular economy. In summary, aluminum coils stand out from other metal coils due to their lightweight, corrosion resistance, high thermal conductivity, malleability, and recyclability. These unique properties make aluminum coils a preferred choice for a wide range of applications across different industries.

- Q: Can aluminum coils be used in the manufacturing of medical devices?

- Yes, aluminum coils can be used in the manufacturing of medical devices. Aluminum is a versatile material that offers several advantages for medical device manufacturing. It is lightweight, corrosion-resistant, and has good thermal conductivity. These properties make aluminum coils suitable for various medical applications such as medical imaging equipment, surgical instruments, and prosthetics. Medical imaging devices, such as MRI and CT scanners, often use aluminum coils to transmit and receive electromagnetic signals. Aluminum's electrical conductivity allows for efficient signal transmission, enhancing the accuracy and quality of medical imaging. Additionally, aluminum's lightweight nature makes it easier to handle and maneuver during medical procedures. Aluminum coils are also used in the manufacturing of surgical instruments. These instruments require materials that are sterilizable, durable, and have high strength. Aluminum meets these requirements, as it can be easily sterilized using various methods, including steam, ethylene oxide, or gamma irradiation. Its durability ensures that the instruments can withstand repeated sterilization cycles without degradation, and its high strength ensures the instruments can withstand the forces applied during surgical procedures. Moreover, aluminum can be employed in the production of prosthetics, such as artificial limbs. Aluminum's lightweight nature makes it an ideal material for creating prosthetic devices that are comfortable for patients to wear and move around with. Additionally, its corrosion-resistant properties make it suitable for long-term use, as it can withstand exposure to body fluids and environmental factors. Overall, aluminum coils can indeed be used in the manufacturing of medical devices. Their lightweight, corrosion-resistant, and electrically conductive properties make them a valuable material for medical applications, contributing to the development of advanced and reliable medical devices.

- Q: Can aluminum coils be used in electrical or electronic applications?

- Aluminum coils find utility in electrical and electronic applications. This material, known for its high conductivity, offers various advantages over alternatives like copper in coil applications. Their lightweight nature renders aluminum coils appropriate for weight-sensitive applications. Furthermore, they possess excellent thermal conductivity, ensuring efficient dissipation of heat. Moreover, aluminum coils exhibit resistance to corrosion, making them durable and suitable for outdoor or high-humidity settings. Nonetheless, it is crucial to acknowledge that aluminum's electrical conductivity is lower than that of copper. Hence, the coil's design and dimensions must be meticulously considered to ensure optimal performance.

- Q: Inquiry about the feasibility of using aluminum coils for crafting jewelry or accessories.

- <p>Yes, you can use aluminum coils to make jewelry or accessories. Aluminum is lightweight, durable, and non-allergenic, making it a popular choice for crafting. It's easy to shape and work with, and it's also cost-effective compared to precious metals. You can create rings, bracelets, necklaces, and various other decorative items. Just ensure you use the right tools and safety precautions when working with metal, and finish your creations with appropriate polishing and sealing to enhance their appearance and longevity.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum coils in food storage.

- <p>Advantages of using aluminum coils for storing food include their excellent heat conductivity, which allows for even heating and cooling, making them ideal for temperature-sensitive food items. They are also lightweight, durable, and resistant to corrosion, which enhances their longevity. Additionally, aluminum coils are recyclable, contributing to environmental sustainability. Disadvantages include potential health concerns due to the leaching of aluminum into food, especially in acidic environments. There's also the risk of denting or scratching the surface, which can compromise the integrity of the coil and lead to contamination. Moreover, aluminum coils may not be suitable for all types of food storage, particularly those requiring airtight or vacuum sealing.</p>

Send your message to us

Decorative Aluminum Coil for Producing ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords