1100-0 Aluminum Coil - PVDF Coated Aluminium Coil for Wall Curtain AA3003

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PVDF Coated aluminium coils are widly used in wall curtains. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. Our paints brands can be PPGI, Becker and China brand paints. It depends on your requirement.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

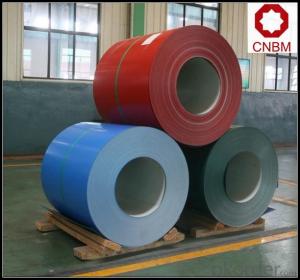

3. Image

4. Products Specification

| Alloy | Temper | Paints | Paints Brand | Period |

| AA3003 | H14 | PVDF | PPGI,Becker,China Brand | 15-20 years |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

What is it Colored aluminum door? Have you seen it? Very much the type of door, sliding doors, folding doors, swing doors, etc., what type do you prefer? What classification Colored aluminum door?

Colored aluminum is the recent rise in the field of doors and windows, a new profile. In fact, almost Colored aluminum and aluminum, but the thickness Colored aluminum thick aluminum than the previous lot, and we had powder coating or electrophoresis. Colored aluminum alloy surface treatment of aluminum alloy performance is very stable and difficult to corrosion, usually surface after special treatment can be guaranteed for at least 30 years without fading LK.

Prospects of Colored aluminum

Surface oxidation-treated Colored aluminum display in the supermarket is very eye-catching. The above not only printed Logo, but also a perfect display of the characteristics of the product sold. Colored aluminum not only promote product sales, but also highlights the corporate image, use the display Colored aluminum is Value for money.

- Q: Are aluminum coils suitable for solar reflectors?

- Yes, aluminum coils are suitable for solar reflectors. Aluminum is a widely used material for solar reflectors due to its high reflectivity and durability. It has a reflective surface that can efficiently redirect the sunlight onto the desired target, such as a solar panel or collector. Additionally, aluminum coils are lightweight and easy to shape, making them ideal for creating curved or angled reflector surfaces. The reflective coating on aluminum coils can withstand harsh weather conditions and provide long-lasting performance. Overall, aluminum coils are an excellent choice for solar reflectors due to their reflectivity, durability, and versatility.

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- You certainly can use aluminum foil to make a cookie cutter like mold. Tear off a long piece, and fold it lengthwise in 1/2 folds, until you have a long strip 1/2 wide. Form this into a circle, and crimp/fold the ends together (trial and error on this). Then, make the heart shape, place in the pan, and make your pancakes. Be sure to spray the aluminum foil each time you pour fresh batter. The pancakes might not come out perfectly shaped, but they will be pretty close. I once did the same thing, in order to make two small hearts on the top of a loaf of pumpkin bread.

- Q: This question asks for methods to assess the quality of aluminum coils, which is important for various industries that use aluminum for manufacturing and construction.

- <p>To check the quality of aluminum coils, you should inspect for surface defects such as scratches, dents, or discoloration. Measure the thickness and width to ensure they meet specifications. Test the hardness and tensile strength to verify mechanical properties. Conduct a chemical analysis to confirm the alloy composition. Check for internal defects using non-destructive testing methods like ultrasonic testing. Assess the coil's flatness and straightness to prevent issues in further processing. Finally, ensure proper packaging and storage conditions to maintain coil quality.</p>

- Q: helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- Honeycombed materials are not strong in all directions. Honeycombed materials are strong in a force at 0 degrees, but will collapse under a teensy force at 90 degrees. Since a car can be damaged from many directions, the use of honeycombed materials would not be ideal. The website I've listed is about the strength of honeycombed materials and is interesting, but does not specifically address your question.

- Q: I've heard many times that it's unhealthy to store or cook food in aluminum, due to leaching, but will this apply to handling aluminum. Also, I heard that most aluminum is coated with a layer of something, to prevent oxidation; is this true?

- Pure soft shiny aluminum develops a thin tenacious layer of aluminum oxide that retards further oxidation (unless worn off). The outer layer of skin is dead horny matter that resists penetration by metal atoms. However, some people do develop allergies to metals and perhaps metals dissolved in sweat (acids?) may get through to live tissue. Handling aluminum may not have been proved harmful but skeptics likely will take less chances.

- Q: How do aluminum coils compare to fiberglass coils in terms of weight?

- Aluminum coils are generally lighter in weight compared to fiberglass coils. Aluminum is known for its lightweight properties, making it an ideal choice for various applications, including coil manufacturing. Fiberglass, on the other hand, tends to be denser and heavier than aluminum. This weight difference can have several advantages when it comes to installation and transportation. Lighter aluminum coils are easier to handle, require less effort to install, and can be more cost-effective in terms of shipping and logistics. Additionally, the reduced weight of aluminum coils can contribute to overall energy efficiency in HVAC systems, as it requires less power to move and circulate air through the coils. However, it's worth noting that the weight comparison between aluminum and fiberglass coils may vary depending on the specific design and thickness of the materials used.

- Q: What are the various applications of aluminum coil in the construction industry?

- <p>Aluminum coil is widely used in construction for various purposes due to its lightweight, durability, and corrosion resistance. It is commonly used in roofing and siding materials for both residential and commercial buildings, providing a long-lasting and low-maintenance option. Aluminum coil is also utilized in the manufacturing of window frames and doors, offering thermal efficiency and strength. Furthermore, it is used in the production of heat exchangers, solar panels, and electrical wiring due to its excellent conductivity. Additionally, aluminum coil is employed in the fabrication of scaffolding and structural components, contributing to the overall stability and safety of construction projects.</p>

- Q: How does the gauge of aluminum coils affect their performance?

- The gauge of aluminum coils directly influences their performance. Thicker gauge coils are more durable and resistant to physical damage, making them suitable for heavy-duty applications that require high strength and durability. On the other hand, thinner gauge coils are lighter and more flexible, making them more suitable for applications that require flexibility and ease of bending. Additionally, the gauge also affects the thermal conductivity and electrical resistance of the coils, with thinner gauges offering higher conductivity. Therefore, the gauge of aluminum coils plays a crucial role in determining their performance characteristics and suitability for specific applications.

- Q: What are the elements and compounds that make up aluminum coils?

- <p>Aluminum coils are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and ductile metal. Pure aluminum is relatively soft, so it is often alloyed with other elements to improve its strength and durability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. These elements can enhance properties like strength, formability, and resistance to corrosion. The specific composition of an aluminum coil can vary depending on the alloy type and the intended application, but the primary component will always be aluminum.</p>

- Q: How are aluminum coils used in the manufacturing of signage?

- Aluminum coils are widely used in the manufacturing of signage due to their numerous beneficial properties. These coils are typically made from high-quality aluminum alloy, which offers excellent corrosion resistance and durability, making them ideal for outdoor applications. The first step in using aluminum coils for signage manufacturing is the process of coil slitting. This involves cutting the large aluminum coils into smaller, more manageable sizes that can be easily shaped and formed to meet specific design requirements. This slitting process ensures that the coils are the right width and thickness for the desired signage application. Once the coils are properly sized, they are typically fed into a roll-forming machine. This machine allows for the precise shaping of the aluminum coils into the desired signage profiles, such as flat panels, letters, or channel letters. The flexibility of aluminum allows for intricate and customized designs to be easily achieved. Aluminum offers great versatility in terms of finishing options. The coils can be coated with various protective finishes, such as polyester or PVDF coatings, which provide enhanced durability and resistance to fading, chipping, or peeling. These finishes also allow for a wide range of color choices, enabling signage manufacturers to create eye-catching and vibrant displays. Furthermore, aluminum coils are lightweight, making them easier to handle during the fabrication process and reducing transportation costs. Their lightweight nature also makes them suitable for mounting on various surfaces, such as walls, poles, or freestanding structures. In summary, aluminum coils play a crucial role in the manufacturing of signage by providing a durable, corrosion-resistant, lightweight, and versatile material. They can be easily shaped and formed to create customized designs, and their protective finishes ensure long-lasting and visually appealing signage displays.

Send your message to us

1100-0 Aluminum Coil - PVDF Coated Aluminium Coil for Wall Curtain AA3003

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords