Streamwood IL Aluminum Coil Anodizing - Brushed Color Coating Aluminum Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Brushed Color Coating Aluminum Coil with High Quality

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Brushed Color Coating Aluminum Coil with High Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Brushed Color Coating Aluminum Coil with High Quality

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

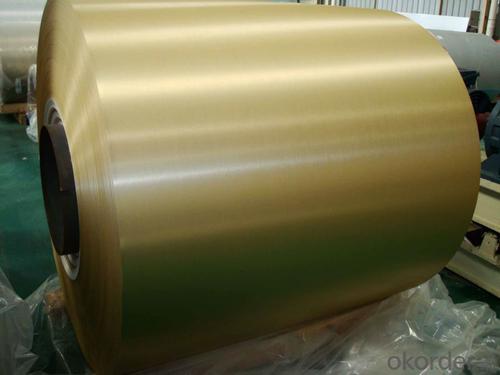

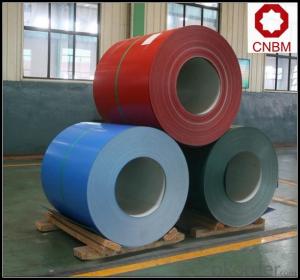

5. Image of Brushed Color Coating Aluminum Coil with High Quality

6. Package and shipping of Brushed Color Coating Aluminum Coil with High Quality

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I want to paint my cars rims and grill metallic pink. But supposedly paint doesn't stick well to aluminum. What can I do to make it stick better and not chip?

- The best way is to have the pieces powder coated. Its a little expensive but the color and luster are outstanding and will last forever.

- Q: Are aluminum coils suitable for lightweight panel applications?

- Indeed, lightweight panel applications can benefit from the use of aluminum coils. Renowned for their lightweight and corrosion-resistant properties, aluminum coils prove to be an exceptional option for these applications. With ease, aluminum coils can be molded and fashioned into panels of various sizes and thicknesses, showcasing their remarkable versatility. Moreover, the high strength-to-weight ratio exhibited by aluminum facilitates the production of robust and enduring lightweight panels. These panels find utility across a range of industries, including automotive, aerospace, construction, and transportation, where the reduction of weight is paramount. All in all, the lightweight nature, corrosion resistance, versatility, and strength of aluminum coils render them a fitting choice for lightweight panel applications.

- Q: What are the safety precautions required when handling aluminum coils?

- When handling aluminum coils, there are several safety precautions that should be followed to ensure the safety of individuals and minimize the risk of accidents. 1. Personal Protective Equipment (PPE): It is essential to wear appropriate PPE, including safety glasses or goggles, gloves, and steel-toed boots. This equipment provides protection against potential injuries caused by sharp edges or flying metal particles. 2. Proper Lifting Techniques: Aluminum coils can be heavy, so it is important to use proper lifting techniques to avoid strains or back injuries. Always lift with your legs, not your back, and use lifting aids or equipment when necessary. 3. Secure Storage and Handling: Store aluminum coils in a well-ventilated area that is free from excessive heat or moisture. It is important to stack them properly and securely to prevent them from falling or rolling, causing injury to nearby individuals. 4. Fire Prevention: Aluminum is highly flammable when in the form of a fine powder or shavings. Therefore, it is crucial to keep the working area clean and free from combustible materials. Additionally, smoking or open flames should be strictly prohibited in the vicinity. 5. Avoid Sharp Edges: Aluminum coils can have sharp edges that can cause cuts or lacerations. Always handle them with care and use appropriate tools or equipment when cutting or shaping the coils to minimize the risk of injury. 6. Training and Education: Proper training and education on handling aluminum coils should be provided to all individuals involved in the process. This includes understanding the material properties, safe handling techniques, and emergency procedures in case of accidents or spills. 7. Chemical Hazards: Aluminum coils may be coated or treated with chemicals. It is important to be aware of any potential hazards associated with these coatings and follow proper safety procedures when handling or working with them. By following these safety precautions, individuals can reduce the risk of accidents, injuries, and potential hazards when handling aluminum coils. It is crucial to prioritize safety and ensure that all employees are trained and equipped with the necessary knowledge and protective gear.

- Q: What are the different types of surface coatings for aluminum coils?

- There are several different types of surface coatings that can be applied to aluminum coils. These coatings serve to protect the aluminum from corrosion, enhance its appearance, and improve its durability. Some of the common types of surface coatings for aluminum coils include: 1. Polyester: Polyester coatings are popular for their excellent color retention and resistance to fading. They provide a smooth, glossy finish and are commonly used for architectural applications. 2. Polyvinylidene Fluoride (PVDF): PVDF coatings offer exceptional weather resistance and durability. They are highly resistant to UV radiation, chemicals, and abrasion, making them suitable for outdoor applications and environments with harsh conditions. 3. Epoxy: Epoxy coatings provide good chemical resistance and adhesion. They are often used in industrial settings where corrosion protection is crucial, such as in chemical processing plants and marine applications. 4. Polyurethane: Polyurethane coatings are known for their durability and resistance to abrasion. They are commonly used in high-traffic areas or applications where the aluminum surface may be subjected to frequent contact or wear. 5. Acrylic: Acrylic coatings offer good weather resistance and color retention. They provide a smooth, glossy finish and are commonly used in architectural and decorative applications. 6. Plastisol: Plastisol coatings are a type of vinyl coating that provides excellent corrosion resistance and flexibility. They are often used in applications where the aluminum surface needs to withstand bending or forming without cracking or peeling. It is important to note that each type of coating has its own unique properties and advantages, and the choice of coating will depend on the specific requirements of the application, such as the level of corrosion resistance, aesthetic preferences, and environmental conditions.

- Q: Is it possible to construct furniture or tables using aluminum coils?

- <p>Yes, aluminum coils can be used to make furniture or tables. Aluminum is a versatile material known for its strength, durability, and lightweight properties. It can be easily bent and shaped into various forms, making it suitable for furniture construction. Aluminum coils can be used to create the frame or support structure of tables and other furniture items. They are also resistant to corrosion and require minimal maintenance, making them a popular choice for outdoor furniture and modern interior designs.</p>

- Q: Is it possible to utilize aluminum coils in the automotive industry?

- <p>Yes, aluminum coils are widely used in the automotive industry. They are employed in various applications such as engine parts, heat exchangers, and body panels due to their lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum's recyclability and energy efficiency in production also contribute to its popularity in vehicle manufacturing.</p>

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending due to their relatively low strength and flexibility.

- Q: How are aluminum coils stored and transported?

- Aluminum coils are typically stored and transported in various ways depending on their size and weight. They are commonly stored in warehouses or outdoor storage facilities, where they are organized and stacked horizontally on pallets or racks. To ensure their protection, coils are often covered with a protective material such as plastic or shrink wrap. When it comes to transportation, aluminum coils are usually loaded onto trucks, containers, or flatbed trailers for long-distance journeys. To prevent damage during transit, the coils are secured using straps, chains, or other fastening methods. Additionally, specialized equipment like coil racks or cradles can be used to provide extra support and stability. Overall, proper storage and transportation practices are crucial to maintain the integrity of aluminum coils and prevent any potential harm.

- Q: And if the deodorant companies know that aluminum causes cancer, why do they keep putting it in their products?

- Aluminium-based complexes react with the electrolytes in the sweat to form a gel plug in the duct of the sweat gland. The plugs prevent the gland from excreting liquid and are removed over time by the natural sloughing of the skin. The metal salts work in another way to prevent sweat from reaching the surface of the skin: the aluminum salts interact with the keratin fibrils in the sweat ducts and form a physical plug that prevents sweat from reaching the skin’s surface. Aluminum salts also have a slight astringent effect on the pores; causing them to contract, further preventing sweat from reaching the surface of the skin.The blockage of a large number of sweat glands reduces the amount of sweat produced in the underarms,

Send your message to us

Streamwood IL Aluminum Coil Anodizing - Brushed Color Coating Aluminum Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords