Carbon Steel Rebar Direct

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical Composition: (Please kindly find our chemistry of our material based on HRB500 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

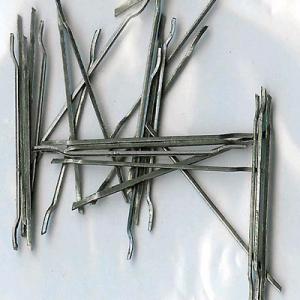

Usage and Applications of HRB400 Deformed Steel Bar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB400 Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

- Q: Are steel rebars suitable for use in structures with high impact resistance requirements?

- Yes, steel rebars are suitable for use in structures with high impact resistance requirements. Steel rebars are known for their high tensile strength and durability, making them ideal for reinforcing concrete structures that need to withstand heavy impacts. They provide additional strength and stability to the construction, ensuring the structure can withstand various external forces and impacts without compromising its integrity.

- Q: How do steel rebars affect the overall thermal stability of a structure?

- Steel rebars can significantly affect the overall thermal stability of a structure due to their thermal conductivity properties. Thermal stability refers to the ability of a structure to withstand changes in temperature without experiencing significant deformation or damage. Steel rebars have high thermal conductivity, which means they can efficiently transfer heat throughout a structure. This property can have both positive and negative effects on the thermal stability of the structure. On the positive side, steel rebars can help in dissipating heat from the structure, preventing the concentration of heat in specific areas. This can prevent localized thermal expansion, which can lead to cracks and structural failures. By evenly distributing heat, steel rebars can improve the overall thermal stability of the structure. On the negative side, steel rebars can also conduct heat to colder areas of the structure, leading to thermal gradients. This can result in differential expansion and contraction, causing stress and potential damage to the structure. Additionally, during fire incidents, steel rebars can rapidly heat up and transfer the heat to the surrounding concrete, reducing its strength and compromising the overall stability of the structure. To mitigate these potential negative effects, engineers and architects must carefully consider the design, placement, and spacing of steel rebars within the structure. By ensuring proper reinforcement layout and utilizing insulation materials, the thermal stability can be enhanced. Additionally, incorporating fire-resistant coatings or insulation around the rebars can help minimize the effects of heat transfer during fire incidents. In conclusion, steel rebars can significantly impact the overall thermal stability of a structure. While their high thermal conductivity can aid in dissipating heat, it can also lead to thermal gradients and potential damage. By carefully considering the design and incorporating appropriate measures, the negative effects of steel rebars on thermal stability can be minimized, ensuring the long-term durability and safety of the structure.

- Q: Can steel rebars be recycled after the demolition of a structure?

- Yes, steel rebars can be recycled after the demolition of a structure. Steel is a highly recyclable material and rebars are commonly collected and reused in the steel industry for the production of new steel products. Recycling steel rebars helps conserve natural resources and reduces the environmental impact of construction projects.

- Q: Are steel rebars suitable for use in aggressive environments?

- Yes, steel rebars are suitable for use in aggressive environments. Steel rebars are commonly used in construction projects, including those in aggressive environments such as coastal areas, chemical plants, and wastewater treatment facilities. They possess excellent durability, strength, and corrosion resistance properties, making them highly suitable for withstanding aggressive elements like saltwater, chemicals, and moisture. Additionally, proper protective coatings can be applied to enhance their resistance to corrosion, ensuring their long-term performance in aggressive environments.

- Q: Can steel rebars be used in the construction of hospitals?

- Yes, steel rebars can be used in the construction of hospitals. Steel rebars are commonly used in reinforced concrete structures to provide strength and stability. In hospital construction, where safety and durability are crucial, steel rebars are essential for reinforcing concrete foundations, columns, beams, and other structural elements. They help ensure the structural integrity of the hospital building, making it resilient and capable of withstanding various loads and potential hazards.

- Q: Can steel rebars be used in the construction of high-speed rail tracks?

- Yes, steel rebars can be used in the construction of high-speed rail tracks. Steel rebars are commonly used as reinforcement in concrete structures, including rail tracks. The high tensile strength of steel rebars provides the necessary stability and support required for high-speed trains, ensuring the tracks can withstand the heavy loads and dynamic forces generated by these trains.

- Q: What are the common manufacturing processes for steel rebars?

- Steel rebars are manufactured through a series of steps to guarantee the production of durable and high-quality reinforcement bars. These steps usually consist of the following: 1. Melting: Initially, raw materials such as iron ore, coal, and limestone are melted in a blast furnace. This process yields molten iron, which is further refined to eliminate impurities. 2. Casting: Subsequently, the refined molten iron is poured into molds, creating large billets or blooms. These molds, commonly known as continuous casting machines, solidify the molten iron into a rectangular form. 3. Rolling: The solidified billets or blooms are then heated and passed through rolling mills. Through this rolling process, the steel is compressed between a series of rollers, reducing its thickness and shaping it into the desired dimensions of rebars. Additionally, this process enhances the mechanical properties of the steel while eliminating any internal defects or impurities. 4. Quenching and Tempering: Following the initial rolling, the rebars may undergo quenching and tempering. Quenching involves rapidly cooling the steel bars by immersing them in water or oil. This step increases the hardness of the rebars, making them more resistant to deformation and wear. Subsequently, tempering involves reheating the quenched bars to a specific temperature and gradually cooling them. This process eliminates internal stresses and improves the toughness of the rebars. 5. Cutting and Coiling: Once the rebars have been rolled and heat-treated, they are cut to the desired lengths using cutting machines. The cut rebars are then either coiled into bundles or stacked for storage and transportation. 6. Surface Treatment: Manufacturers often apply a protective coating or surface treatment to enhance the corrosion resistance of rebars. This can be achieved through hot-dip galvanizing, where the rebars are immersed in molten zinc to form a zinc coating, or epoxy coating, where a layer of epoxy resin is applied to the rebars. It is crucial to note that these manufacturing processes may vary depending on the specific requirements and standards set by different countries and industries. Nevertheless, the aforementioned steps provide a general overview of the common processes involved in manufacturing steel rebars.

- Q: What is the typical weight of a steel rebar?

- The weight of a steel rebar can vary depending on its diameter and length, resulting in different typical weights. However, in construction projects, the most commonly used steel rebar is usually 20 feet long and has a diameter ranging from 1/2 inch to 1 inch. In terms of weight, this standard size can range from approximately 7.5 pounds to 24 pounds per linear foot. Consequently, a 20-foot steel rebar can weigh anywhere between roughly 150 pounds to 480 pounds. It is worth noting that weight standards for steel rebars may differ between countries, so it is always recommended to refer to local specifications and standards for accurate information.

- Q: What is the manufacturing process of the hot rolled thread steel production line?

- The billets used in continuous small mills are generally continuous billets, the length of which is usually 130~160mm, the length is about 6~12 meters, and the billets are 1.5~3 tons in weight. The rolling line is mostly flat interchange arrangement to realize all round rolling without torsion. According to different billet specifications and finished sizes, there are 18, 20, 22 and 24 small mills, 18 of which are mainstream. The use of bar rolling reheating furnace, high pressure water descaling, in addition to the new technology of low-temperature rolling, endless rolling, rolling, rolling development to adapt and improve the precision of rolling billet, rolling mill is mainly to improve the accuracy and speed (up to 18m/s).

- Q: How are steel rebars manufactured?

- Steel rebars are manufactured through a process called rolling, where steel billets are heated and passed through a series of rollers to shape them into the desired rebar sizes and profiles. This process ensures the rebars have the necessary strength and durability for construction purposes.

Send your message to us

Carbon Steel Rebar Direct

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords