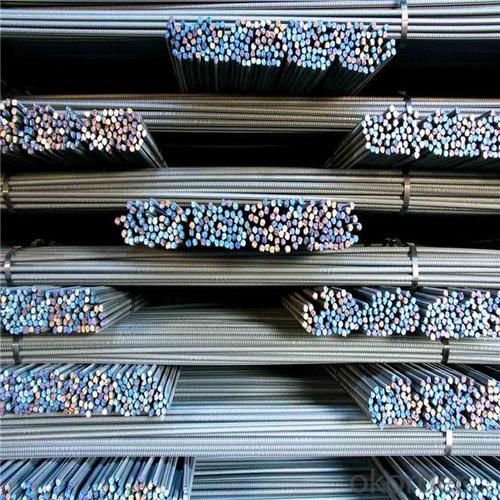

Steel rebar with short delivery time and quality certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar is made of unfinished steel, making it susceptible to rusting. As rust takes up greater volume than the iron

or steel from which it was formed, it causes severe internal pressure on the surrounding concrete, leading to cracking,

spalling, and ultimately, structural failure. This is a particular problem where the concrete is exposed to salt water, as

in bridges built in areas where salt is applied to roadways in winter, or in marine applications. Epoxy-coated rebar or

stainless steel rebar may be employed in these situations at greater initial expense, but significantly lower expense

over the service life of the project. Fiber-reinforced polymer rebar is now also being used in high-corrosion environments

Most grades of steel used in rebar cannot accept welding; such as, to adjacent steel plates or as means to bind single

pieces of rebar together. However, special grades of rebar steel and welding rods make welding by expert welders possible.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered

with special plastic "mushroom" caps.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: Can steel rebars corrode or rust over time?

- Yes, steel rebars can corrode or rust over time.

- Q: How do steel rebars affect the aesthetics of a construction project?

- Steel rebars, an essential element of reinforced concrete structures, have a significant influence on the aesthetics of construction projects. Although their primary purpose is to provide strength and reinforcement to concrete, their presence can have an impact on the overall appearance of the project. The visibility of steel rebars is one way they affect aesthetics. In infrastructure projects like bridges or parking garages, it is common to leave rebars exposed during construction. This exposure can create a distinct industrial or modern look that some find aesthetically pleasing. Architects and designers may intentionally embrace this raw and utilitarian appearance to achieve a specific aesthetic vision. However, in many architectural projects, particularly those involving residential or commercial buildings, the visibility of steel rebars is often undesirable. In such cases, rebars are typically concealed within the structure and covered with finishes such as concrete, plaster, or decorative cladding. This approach enhances the aesthetics of the construction project by shifting the focus from structural elements to the overall design and finishes. Furthermore, the placement and arrangement of rebars can also impact aesthetics. In intricate architectural designs, rebars must be precisely positioned to ensure the desired structural integrity. This presents challenges for designers as they strive to achieve functionality and visual appeal. However, with careful planning and coordination, rebars can be strategically placed to minimize their visual impact while maintaining the desired aesthetics of the project. It is important to note that aesthetics should never compromise the safety and structural integrity of a construction project. While efforts can be made to conceal or minimize the visual impact of steel rebars, proper installation and adherence to engineering standards must always take priority. Ultimately, the aesthetic impact of steel rebars on a construction project depends on the design intent, architectural style, and the balance between functionality and visual appeal.

- Q: How do steel rebars contribute to the overall aesthetics of a structure?

- Steel rebars do not necessarily contribute to the overall aesthetics of a structure as they are typically hidden within the concrete. However, they play a crucial role in reinforcing the concrete, ensuring structural integrity, and enhancing the durability and longevity of the building.

- Q: Are steel rebars suitable for use in structures with high wind loads?

- Yes, steel rebars are suitable for use in structures with high wind loads. Steel rebars provide strength and reinforcement to concrete structures, making them more resistant to high winds and ensuring the overall stability and durability of the structure.

- Q: How is steel rebar manufactured?

- Steel rebar, or reinforcing bar, is manufactured through a process known as steelmaking. The manufacturing process involves several steps to ensure the production of high-quality and durable rebar. The first step in manufacturing steel rebar is the selection and preparation of raw materials. Iron ore, coal, and limestone are the primary raw materials used in steelmaking. Iron ore is extracted from mines and then processed to remove impurities. Coal is used as a fuel source to heat the iron ore, while limestone acts as a flux to remove impurities during the heating process. Once the raw materials are prepared, they are combined in a blast furnace. The blast furnace is a large, cylindrical structure where the iron ore, coal, and limestone are heated to extreme temperatures. The intense heat causes a chemical reaction that separates the iron from the impurities, resulting in molten iron. The molten iron is then transferred to a basic oxygen furnace (BOF) or an electric arc furnace (EAF). In the BOF process, the molten iron is combined with scrap steel and other alloys to create the desired steel composition. Oxygen is blown into the furnace, which removes impurities and adjusts the carbon content. In the EAF process, electricity is used to melt the scrap steel and other alloys, and chemical reactions occur to adjust the composition and remove impurities. After the steel has been produced, it is poured into continuous casting machines, which shape the steel into long, rectangular strands called billets. These billets are then passed through a series of rolling mills, which gradually reduce their size and shape them into the desired cross-sectional profile. The rolling process also enhances the strength and durability of the steel. Once the rebar has been rolled, it undergoes a process called quenching and tempering. This involves rapidly cooling the rebar in water to increase its hardness, followed by reheating it to a specific temperature and then cooling it slowly. This process helps improve the rebar's strength and ductility, making it suitable for reinforcement in concrete structures. Finally, the rebar is cut into desired lengths and often undergoes surface treatment, such as galvanization or epoxy coating, to enhance its corrosion resistance. It is then bundled and shipped to construction sites, where it is used to reinforce concrete structures like buildings, bridges, and roads. In summary, the manufacturing of steel rebar involves the selection and preparation of raw materials, the melting and refining of iron in a blast furnace or electric arc furnace, the shaping of the steel into billets through continuous casting and rolling, the quenching and tempering process to improve its strength and ductility, and the final cutting and surface treatment before it is ready for use in construction projects.

- Q: How do steel rebars improve the structural integrity of a building?

- Enhancing the structural integrity of buildings, steel rebars, also known as reinforcement bars, play a crucial role. Used in concrete construction, they provide strength, durability, and resistance against different forces that a structure may face. One way in which steel rebars enhance the structural integrity of a building is by increasing its load-bearing capacity. When rebars reinforce concrete, it becomes more capable of withstanding heavy loads and forces generated by gravity, wind, earthquakes, or dynamic loads from human activities. Acting as a network of reinforcement, the rebars distribute the load evenly throughout the structure, preventing excessive deflection and minimizing the risk of structural failure. Furthermore, steel rebars improve the tensile strength of concrete, which is traditionally weak in tension. While concrete is excellent at bearing compression forces, it lacks the ability to efficiently resist pulling or stretching forces. By incorporating rebars into the concrete, the combination of materials works together to withstand compression and tension forces more effectively. This prevents cracks and fractures from spreading in the concrete, as the rebars act as a support system that holds the structure together. Another advantage of using steel rebars is their resistance to corrosion. Steel is highly durable and can withstand harsh environmental conditions, reducing the risk of degradation over time. This ensures the longevity of the building's structural elements and reduces the need for expensive repairs or replacements. Additionally, steel rebars offer flexibility in design and construction. They can be molded into various shapes and sizes to meet specific structural requirements, allowing for optimal distribution of reinforcement where it is most needed. This flexibility enables architects and engineers to design buildings that are aesthetically pleasing and safe, without compromising on structural integrity. In conclusion, steel rebars significantly enhance the structural integrity of buildings by increasing load-bearing capacity, improving tensile strength, resisting corrosion, and providing design flexibility. By reinforcing concrete, they ensure that structures are better equipped to withstand various forces and maintain stability and safety over time.

- Q: What are the common grades of steel rebars?

- The common grades of steel rebars include Grade 40, Grade 60, and Grade 75.

- Q: How much does a futures screw do?

- How much is one hand steel futures: the emphasis in the futures market is the margin system, which is one of the differences between the stock markets. The so-called margin system, if the margin is 10%, then you only use the actual price of 10% of the price can be traded.With the delivery day approaching, the margin will gradually increase.Margin = hand screw thread steel per ton steel price * * tonnage margin ratio, if the steel price is now 1900, steel is a hand of 10 tons, the hand margin is 1900 yuan / ton *10%=1900 yuan *10 tons.

- Q: Can steel rebars be used for both residential and commercial constructions?

- Yes, steel rebars can be used for both residential and commercial constructions. Steel rebars are commonly used as reinforcement in concrete structures, providing strength and stability to the building. Whether it is a residential house or a commercial building, steel rebars are essential components in the construction process to ensure the durability and structural integrity of the structure.

- Q: How do steel rebars provide structural stability and strength to buildings?

- Steel rebars provide structural stability and strength to buildings by reinforcing the concrete. They are embedded within the concrete, creating a composite material that can withstand tensile forces. This prevents cracking and enhances the structural integrity of the building, allowing it to bear heavy loads and resist external forces such as earthquakes or high winds. The combination of steel rebars and concrete creates a durable and robust structure, ensuring the safety and longevity of the building.

Send your message to us

Steel rebar with short delivery time and quality certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords