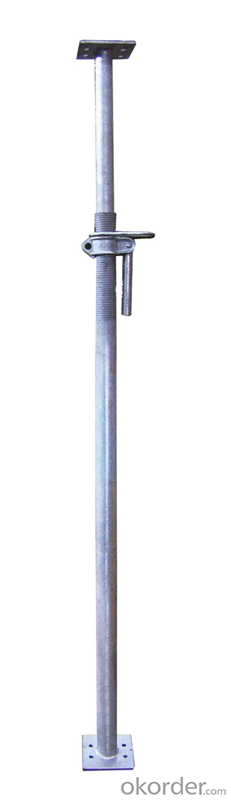

Construction Adjustable Steel Shoring Prop

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: How do steel props contribute to the overall speed of construction projects?

- Adjustable steel props, also called acrow props or steel supports, play a crucial role in expediting construction projects by offering temporary support to structures during the building process. These props are commonly utilized for supporting beams, slabs, walls, and other structural components. One of the primary ways steel props aid in the overall speed of construction projects is by facilitating faster and safer formwork and concreting operations. By providing temporary support, they help evenly distribute the load and prevent the structure from collapsing or deforming. This enables construction workers to work more efficiently and confidently, without any delays or concerns regarding the stability of the structure. Furthermore, the adjustability of steel props in terms of height enhances their versatility and time-saving capabilities. Construction projects often necessitate varying levels of support as the building progresses. With steel props, contractors can effortlessly adjust the height to accommodate changes in the structure, such as different floor levels or varying load requirements. This eliminates the need for customized supports and allows for a quicker and more flexible construction process. Moreover, steel props are relatively lightweight and easy to handle, further contributing to the speed of construction projects. Their lightweight nature makes them simple to transport, maneuver, and install on-site. This saves valuable time and resources that would otherwise be expended on heavier and more intricate support systems. Additionally, steel props are durable and boast a high load-bearing capacity. This means they can withstand significant weights and pressures without compromising the stability of the structure. The robustness of steel props enables construction workers to proceed swiftly and efficiently with their tasks, without worrying about support failure or the need for frequent adjustments. In conclusion, steel props play a significant role in expediting construction projects by providing temporary support, ensuring structural stability, allowing for easy height adjustments, being lightweight and easy to handle, and possessing a high load-bearing capacity. These factors enable construction workers to work efficiently, save time, and progress swiftly, ultimately accelerating the completion of construction projects.

- Q: What are the common safety certifications or standards for steel props?

- Some common safety certifications or standards for steel props include the European Standard EN 1065, the British Standard BS 4074, and the Australian/New Zealand Standard AS/NZS 3610. These standards ensure that steel props are designed, manufactured, and tested to meet specific safety requirements, providing assurance of their strength, stability, and load-bearing capacity.

- Q: Can steel props be used for temporary support in railway station construction?

- Yes, steel props can be used for temporary support in railway station construction. Steel props are commonly used in construction projects to provide temporary support to structures during the construction process. They are versatile and can be adjusted to different heights and load capacities, making them suitable for supporting various structures including railway stations.

- Q: Can steel props be used for temporary roof support?

- Yes, steel props can be used for temporary roof support. Steel props, also known as scaffolding props or acrow props, are adjustable telescopic poles made of steel that are commonly used in construction projects. They are designed to provide temporary support for various structures, including roofs. Steel props are able to bear heavy loads and can be easily adjusted to the desired height, making them suitable for temporary roof support. They are commonly used in situations where additional support is needed during construction, renovation, or repair work on roofs. However, it is important to ensure that the steel props are properly installed and meet the required safety standards to ensure the stability and integrity of the temporary roof support.

- Q: How do you ensure proper load distribution when using multiple steel props?

- Proper load distribution when using multiple steel props can be ensured by following a few essential steps. Firstly, it is important to determine the total load that needs to be supported and distribute it evenly among the props based on their load-bearing capacities. Secondly, the props should be positioned at regular intervals along the load-bearing structure to provide adequate support and prevent any excessive load on a single prop. Additionally, the props should be properly aligned and adjusted to ensure they are all carrying their fair share of the load. Regular monitoring and adjustment of the props during the construction process also help in maintaining proper load distribution.

- Q: Can steel props be used in bridge construction projects?

- Indeed, bridge construction projects can employ steel props. In construction undertakings, steel props are frequently utilized to offer temporary support to structures throughout the construction or repair process. With their adjustability and ease of installation and removal, they serve as a versatile and economical solution for numerous construction applications, including bridge construction. By utilizing steel props, the weight of the bridge segments can be adequately supported during construction, guaranteeing stability and safety. Furthermore, they can be easily adjusted to suit various bridge designs and construction techniques. Consequently, steel props emerge as a dependable and extensively utilized tool in bridge construction projects.

- Q: Can steel props be used in hospital construction?

- Yes, steel props can be used in hospital construction. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction projects to provide temporary support to structures. They are versatile and can be adjusted to different heights, making them suitable for various applications, including hospital construction. In hospital construction, steel props can be used for various purposes. They can provide support to ceilings, walls, and beams during the construction process. Steel props can also be used to support temporary structures such as scaffolding or formwork, which are essential for construction activities. Additionally, steel props are known for their strength and stability, which makes them a reliable choice for hospital construction. Hospitals require structures that can withstand heavy loads and provide a safe environment for patients and staff. Steel props, being made from high-quality steel, offer the necessary strength and stability required in such critical infrastructure projects. Moreover, steel props are adjustable, allowing for easy installation and adaptation to changing construction needs. Hospital construction often involves complex designs and layouts, and steel props can be easily adjusted to different heights and angles to accommodate these requirements. Furthermore, steel props are durable and long-lasting, making them a cost-effective solution for hospital construction. Hospitals are long-term investments, and using steel props ensures the longevity and stability of the structures, reducing the need for frequent repairs or replacements. Overall, steel props can indeed be used in hospital construction. Their strength, stability, adjustability, and durability make them an ideal choice for supporting various structures during the construction process.

- Q: What are the common safety features and mechanisms found in steel props?

- Some common safety features and mechanisms found in steel props include adjustable height settings, sturdy base plates for stability, locking pins or clips to secure the prop in place, and load-bearing capacity indicators to ensure safe weight distribution. Additionally, many steel props are designed with anti-slip surfaces and reinforced construction to prevent accidents or collapses.

- Q: Are steel props suitable for use in tunnel ventilation system installation?

- Yes, steel props are suitable for use in tunnel ventilation system installations. Steel props are commonly used to support tunnel walls and ceilings during construction and maintenance activities. They are strong, durable, and have the ability to withstand heavy loads, making them ideal for providing stability and support in tunnel ventilation systems. Additionally, steel props can be easily adjusted and secured in place, allowing for flexibility in positioning the ventilation equipment and ensuring proper airflow in the tunnel. Overall, steel props are a reliable and practical choice for use in tunnel ventilation system installations.

- Q: How do you ensure proper anchoring of steel props?

- To ensure proper anchoring of steel props, there are a few important steps to follow. Firstly, it is crucial to select the right type and size of anchor for the specific application. The anchor should be able to withstand the load and forces exerted on the steel props. Next, the anchor should be installed correctly according to the manufacturer's instructions. This typically involves drilling a hole in the concrete or other structural material, inserting the anchor, and then tightening it securely. It is important to ensure that the anchor is installed at the correct depth and angle to provide optimal support and stability. This may require using specialized tools or equipment to accurately position the anchor. Additionally, proper inspection and testing should be conducted to ensure that the anchor is securely fastened and capable of withstanding the anticipated loads. This may involve load testing or other forms of assessment to verify the anchor's strength. Regular maintenance and monitoring of the steel props and anchors is also essential to ensure ongoing stability and safety. This includes checking for any signs of damage, corrosion, or loosening of the anchor, and taking appropriate corrective actions if needed. Overall, proper anchoring of steel props requires careful consideration of the specific application, correct installation techniques, thorough inspection and testing, and regular maintenance to ensure optimal stability and safety.

Send your message to us

Construction Adjustable Steel Shoring Prop

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords