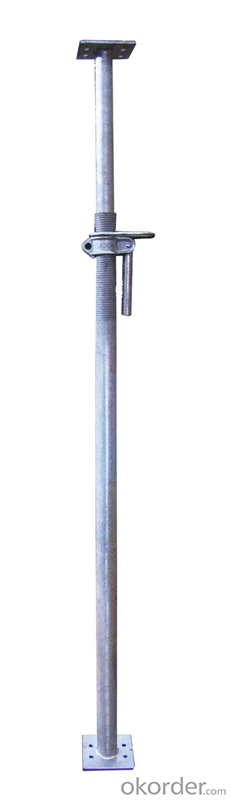

Adjustable Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product information:

Model Number: GTJ-P003

Name: Q235 High Quality Steel Slab Props

Material: Q235

Thickness: 1.6mm to3mm or as your requirements

Surface Treatment: as per requirements

Standard: use your standard or international standard

Dimension: Light duty 40-48mm, MID Duty 48-56/58mm, Heavy duty 48-60mm

Characteristics:

1. Reliable performance

2. Corrosion resistance

3. Durable finish standards

Functions

It is used for construction supporting, timber, formwork, concrete slab and so on. It is very easy and reliable to use

Why Choose Us

1. We are experienced manufacturer in Hebei with more than 4 years experience and cooperating with more many countries.

2. We supply qualified products which are certified by SGS and ISO9001:2008. Strict QC to make sure your profit.

3. Timely delivery can be guaranteed because we have a factory which covers an area of 30000sqm and its daily output is more than 50 tons.

4. A competitive price can be offered because we are a professional manufacturer of scaffolding with an advantage on cost-controlling & production management.

- Q: Are steel props suitable for use in the construction of theaters?

- Yes, steel props are commonly used in the construction of theaters due to their durability, strength, and stability. They provide necessary support for stage sets, backdrops, and lighting equipment, ensuring the safety and structural integrity of the theater.

- Q: Can steel props be used in elevated platforms or walkways?

- Indeed, elevated platforms or walkways can indeed make advantageous use of steel props. These props, also referred to as scaffolding props or shoring props, are frequently employed to bolster scaffolding structures during construction or maintenance endeavors. Their primary purpose is to furnish temporary support and stability to elevated platforms or walkways, thereby ensuring the well-being of laborers and materials. The adjustable height feature of steel props renders them versatile and well-suited to diverse applications. Moreover, they bestow a robust and dependable support system, capable of withstanding substantial burdens and upholding stability in elevated structures. Consequently, steel props represent a fitting choice for implementation in elevated platforms or walkways.

- Q: What is the maximum angle of inclination that a steel prop can withstand?

- The maximum angle of inclination that a steel prop can withstand depends on various factors such as the specific type of steel, its dimensions, and the load it is supporting. However, steel props generally have a maximum angle of inclination of around 45 to 60 degrees. It is essential to consult the manufacturer or relevant engineering guidelines for accurate information regarding the maximum angle of inclination for a specific steel prop.

- Q: In the construction of the formwork support frame must be equipped with vertical and horizontal floor bar? Built in 26 meters of concrete surface, set up a height of 3.6 meters

- According to the JGJ130-2011 (construction of steel tubular scaffold safety technical specifications), article 6.3.2 provides that the scaffolding must be equipped with vertical and horizontal sweeping rod. Vertical sweep rod should be fixed at right angles from the bottom of the steel pipe is not more than 200mm of the vertical pole. The transverse sweeping rod shall be fixed by a right angle fastener close to the vertical rod below the vertical sweeping rod.

- Q: Can steel props be used in supporting temporary exhibition booths?

- Temporary exhibition booths can indeed benefit from the use of steel props. These props provide a robust and dependable support system for structures of this nature. They offer the added advantage of adjustability, as their height can be modified to accommodate various locations or uneven surfaces. Moreover, steel props are highly regarded for their ability to bear heavy loads, making them an ideal choice for supporting exhibition materials, displays, and equipment. Furthermore, their durability and resistance to wear and tear ensure the stability and safety of the temporary booth throughout its usage. All in all, steel props are widely favored in the construction and support of temporary exhibition booths due to their strength, versatility, and reliability.

- Q: Can steel props be used in bridge construction projects?

- Yes, steel props can be used in bridge construction projects. Steel props provide sturdy support and stability during the construction process, making them a common choice for bridge construction. They are capable of handling heavy loads and can be easily adjusted to accommodate different bridge designs and construction phases.

- Q: How long does a steel prop typically last?

- A steel prop typically lasts for several years, depending on the frequency of use, the load it supports, and the maintenance provided.

- Q: How do you prevent steel props from sinking in wet soil?

- In order to prevent steel props from sinking in wet soil, there are several strategies that can be employed: 1. Enlarge the surface area: A highly effective method involves utilizing larger steel plates or base plates at the bottom of the props. These plates should be wider than the props themselves, distributing the load over a larger area and minimizing the risk of sinking. 2. Employ adjustable props: Consider the use of adjustable steel props that can be extended or shortened as needed. This allows for the adjustment of prop height to accommodate varying soil conditions, ensuring stability and security. 3. Provide additional support: In cases where the soil is extremely wet or unstable, it may be necessary to provide extra support to the steel props. This can be achieved by driving wooden or steel beams into the ground at an angle, creating a diagonal brace that offers additional stability. 4. Establish a stable base: It is crucial to prepare a stable base in the wet soil prior to prop installation. This can be accomplished by excavating the area and replacing the wet soil with a layer of compacted gravel or crushed stone. These materials provide a solid and stable foundation for the props. 5. Implement dewatering techniques: If the soil consistently remains wet, implementing dewatering techniques can help reduce moisture content. This can be accomplished through methods such as installing drainage pipes or using pumps to remove excess water from the area. By reducing the water content in the soil, stability can be improved, and the sinking of steel props can be prevented. Remember, it is essential to consult with a structural engineer or construction professional to assess the specific soil conditions and determine the most suitable solution for preventing steel props from sinking in wet soil.

- Q: How do steel props contribute to the overall safety of construction sites?

- Playing a crucial role in ensuring construction site safety are steel props, also known as adjustable steel props or acrow props. These durable and sturdy supports are designed to provide temporary structural support and stability during construction activities, minimizing the risk of accidents and enhancing worker, equipment, and environmental safety. A primary contribution of steel props to construction site safety lies in their ability to bear heavy loads and offer reliable support. These props are specially engineered to withstand immense pressure and maintain structural integrity, which is vital when supporting structures like walls, ceilings, or beams during construction or renovation. By securely propping up these temporary structures, steel props prevent collapse and potential harm to workers and nearby structures. Adjustability is another essential aspect of steel props. With their telescopic design, these props can easily be extended or retracted to the desired height, enabling precise and accurate support in different construction scenarios. This adjustability ensures that temporary structures receive adequate support and allows workers to maintain a level and stable working environment, reducing the risk of slips, trips, and falls. Steel props also provide a versatile solution to various construction challenges. They can be used for formwork support, trench shoring, facade retention, and temporary propping, offering a flexible and adaptable approach to construction support. This versatility aids in maintaining stability and mitigating potential hazards on construction sites. Furthermore, steel props are designed with safety features like locking pins and adjustable attachments that prevent accidental displacement or collapse. These additional measures ensure that props remain securely in place, even under dynamic loads or adverse weather conditions, further enhancing construction site safety. In conclusion, steel props significantly contribute to construction site safety by offering reliable support, adjustability, versatility, and safety features. By preventing structural collapse, maintaining stability, and creating a secure working environment, these props play a vital role in safeguarding workers, equipment, and the surrounding areas during construction activities.

- Q: How do you adjust the height of a steel prop?

- To adjust the height of a steel prop, you need to follow a systematic process. Here are the steps to adjust the height of a steel prop: 1. Inspect the prop: Before adjusting the height, ensure that the steel prop is in good condition and not damaged. Check for any cracks, bends, or defects that may affect its stability. 2. Determine the required height: Measure the distance between the ground or supporting surface and the desired height for the prop. This will help you determine how much adjustment is needed. 3. Loosen the locking mechanism: Most steel props have a locking mechanism, usually a pin or a collar, to secure the height adjustment. Locate this mechanism and loosen it to allow movement of the prop. 4. Adjust the height: Depending on the type of steel prop, there are different ways to adjust the height. If it is a telescopic prop, you can extend or retract the sections to achieve the desired height. For a screw-type prop, rotate the threaded rod clockwise or counterclockwise to raise or lower the prop respectively. 5. Secure the adjusted height: Once you have set the correct height, tighten the locking mechanism to secure the prop in place. Ensure that it is firmly locked to prevent any accidental movement. 6. Test stability: After adjusting the height, check the stability of the prop by applying some weight or pressure on it. Ensure that it remains steady and does not wobble or shift. If there are any stability issues, reassess the height adjustment and make necessary corrections. Remember to exercise caution and follow the manufacturer's guidelines when adjusting steel props. If you are unsure or inexperienced, it is advisable to seek assistance from a professional or someone with expertise in using steel props.

Send your message to us

Adjustable Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords