Tripod & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

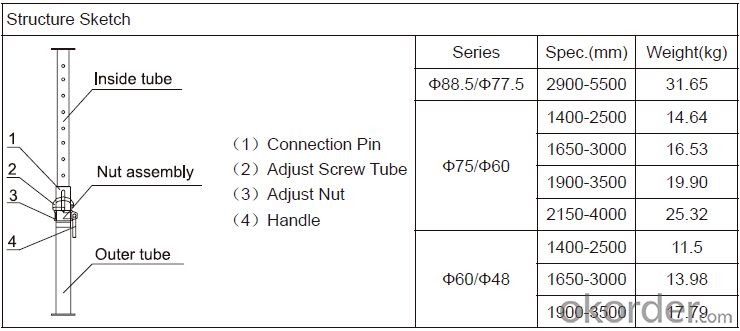

Steel Prop & Tripod & Beam Clamp

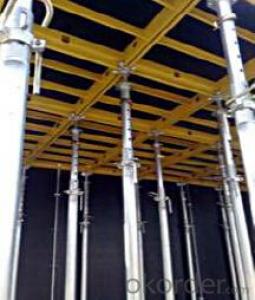

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

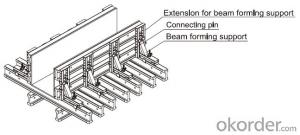

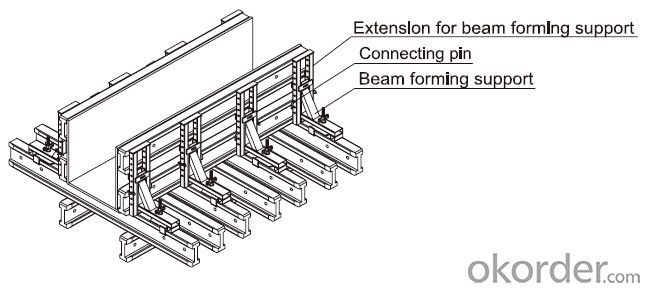

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used in the construction of temporary religious or worship structures?

- Yes, steel props can be used in the construction of temporary religious or worship structures. Steel props provide sturdy support and can withstand heavy loads, making them suitable for temporary structures such as tents or temporary worship spaces. They offer stability and safety, ensuring the structure is secure and reliable during religious and worship activities.

- Q: What are the main differences between adjustable and non-adjustable steel props?

- The main differences between adjustable and non-adjustable steel props lie in their functionality and versatility. Adjustable steel props allow for height adjustment, making them suitable for various construction projects where the height of the supported structure may need to be altered. On the other hand, non-adjustable steel props have a fixed height and are typically used in situations where the height requirement remains constant throughout the project. Additionally, adjustable steel props offer increased flexibility and adaptability, as they can be easily extended or reduced in height, while non-adjustable props are more rigid and limited in their applications.

- Q: Can steel props be used in the construction of temporary parking structures?

- Indeed, temporary parking structures can incorporate steel props in their construction. Commonly referred to as steel shores or steel supports, these props are frequently employed in the construction industry to offer provisional stability and support to structures throughout the building process. Their adjustability and ease of installation render them highly suitable for temporary structures like parking lots. Renowned for their strength and durability, steel props possess the ability to bear substantial loads, a critical requirement for parking structures accommodating vehicles. Furthermore, these props can be dismantled and reused effortlessly, rendering them a cost-efficient option for temporary parking structures.

- Q: Are steel props easy to transport and store?

- Yes, steel props are relatively easy to transport and store. Steel props, also known as adjustable steel props or steel shore props, are commonly used in construction and building projects to provide temporary support to structures. They are lightweight and can be easily disassembled and folded, making them convenient to transport from one location to another. Additionally, steel props are stackable, allowing for efficient storage in warehouses or construction sites. Their compact design and ease of handling contribute to their overall convenience in transportation and storage.

- Q: Are there any safety precautions that need to be taken when using steel props?

- Yes, there are several safety precautions that need to be taken when using steel props. Firstly, it is important to ensure that the props are properly inspected before use to check for any signs of damage or wear. They should also be correctly rated for the load they will be supporting. Additionally, it is crucial to follow the manufacturer's guidelines and instructions for proper installation and adjustment of the props. Proper bracing and support should also be provided to prevent any accidental collapse. Regular monitoring and maintenance of the props during use are essential to identify any potential issues and address them promptly. Lastly, it is crucial to provide adequate training and supervision to the workers using the props to ensure their safety.

- Q: Do steel props require any special accessories for installation and use?

- Yes, steel props require special accessories for installation and use. Some of the common accessories needed include base plates, connectors, and pins. Base plates are used to provide stability and support to the steel props by spreading the load over a wider surface area. Connectors are used to join multiple steel props together to form a continuous support system. Pins are used to secure the connectors and props in place, preventing any movement or collapse. Additionally, accessories such as adjustable heads may be required to provide flexibility in adjusting the height of the steel props according to the specific requirements of the construction project. Overall, these special accessories are essential for ensuring the safe and effective installation and use of steel props in construction activities.

- Q: Are steel props used in commercial construction projects?

- Commercial construction projects commonly utilize steel props. These props, also known as adjustable steel props or steel shores, serve as temporary supports that provide stability and load-bearing capacity throughout the construction process. Their primary function is to support formwork, scaffolding, and other structural elements. Steel props are highly favored in commercial construction due to their durability, strength, and versatility. They can easily be adjusted to different heights and are capable of supporting heavy loads. Furthermore, steel props are resistant to fire, corrosion, and pests, ensuring their reliability for long-term use in commercial buildings. In the realm of commercial construction, steel props find application in various scenarios. They are utilized to support slabs, beams, columns, and walls during concrete pouring or installation. Additionally, steel props are frequently employed to support temporary structures like scaffolding and shoring systems. All in all, steel props play a crucial role in guaranteeing the safety and stability of commercial construction projects. Their capacity to provide temporary support and withstand heavy loads renders them an indispensable tool for contractors and builders within the industry.

- Q: How do you prevent accidents caused by falling steel props?

- There are several measures that can be taken to prevent accidents caused by falling steel props. These include: 1. Regularly inspecting and maintaining the steel props to check for wear, damage, or rust. Any damaged props should be replaced or repaired immediately to maintain their structural integrity. Additionally, regularly lubricating moving parts can prevent them from getting stuck or malfunctioning. 2. Ensuring proper installation of the steel props according to the manufacturer's guidelines. Using appropriate tools and techniques will guarantee a stable and secure installation. It is important to avoid overloading the props beyond their specified capacity. 3. Providing adequate support by using additional systems like braces or shoring. These support systems must be properly installed and adjusted to ensure maximum safety, preventing the props from tipping or falling. 4. Offering training and supervision to workers responsible for installing and working with steel props. Educating them on correct procedures for installation, adjustment, and removal will minimize the risk of accidents. Regular supervision is necessary to ensure compliance with safety protocols. 5. Maintaining a clear work area around the steel props by removing any debris, tools, or equipment that may cause tripping hazards. A clean and organized workspace reduces the risk of accidents caused by slips or falls. 6. Equipping workers with appropriate personal protective equipment (PPE) such as hard hats and safety boots to protect them from falling objects and other potential hazards. 7. Conducting regular safety meetings to emphasize the importance of following safety protocols when working with steel props. Addressing worker concerns and promoting a culture of safety awareness and communication is crucial. By implementing these preventive measures, the risk of accidents caused by falling steel props can be significantly reduced, creating a safer working environment for all individuals involved.

- Q: Can steel props be used for supporting temporary elevated platforms?

- Yes, steel props can be used for supporting temporary elevated platforms. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary structures to provide support and stability. They are designed to be easily adjustable in height, making them ideal for supporting platforms at different elevations. Steel props are strong and durable, capable of withstanding heavy loads and providing a secure base for elevated platforms. Additionally, their versatility and ease of use make them a popular choice for temporary structures in various industries.

- Q: How do steel props contribute to the overall cost of a construction project?

- Steel props, also known as adjustable steel props or scaffolding props, play a significant role in the overall cost of a construction project. These temporary structural supports are used to provide stability and load-bearing capacity for various construction activities such as formwork, concrete pouring, and shoring. One of the primary ways in which steel props contribute to the overall cost is through their rental or purchase expenses. Construction projects often require a large number of props, and these costs can quickly add up. However, it is worth noting that while the initial investment may seem substantial, steel props are reusable and durable, making them a cost-effective solution in the long run. Furthermore, steel props contribute to the overall cost by reducing labor expenses. Their adjustable height feature allows for quick and easy installation, saving considerable time and effort compared to traditional wooden supports. This efficiency translates into reduced labor costs, as fewer workers are required to set up and dismantle the props. Steel props also enhance safety on construction sites, which ultimately impacts the project's overall cost. By providing sturdy support, they help prevent accidents and structural failures, reducing the likelihood of costly damages or injuries. Moreover, their load-bearing capacity ensures the stability of formwork and other construction elements, minimizing the need for repairs or rework, which can be time-consuming and expensive. Additionally, steel props contribute to the overall cost by offering flexibility and adaptability. Their adjustable nature allows for easy modifications to accommodate varying heights and load requirements. This versatility eliminates the need for custom-made supports and expensive alterations, ultimately reducing project costs. Lastly, steel props contribute to cost savings through their versatility and reusability. They can be used across multiple projects, minimizing the need for frequent repurchasing or rental expenses. Additionally, their durability ensures a longer lifespan, reducing maintenance and replacement costs. In conclusion, while steel props may incur initial expenses, their cost-saving benefits are substantial. From reducing labor expenses and enhancing safety to offering flexibility and reusability, steel props contribute significantly to the overall cost of a construction project. Their efficiency and durability make them a valuable investment, ultimately resulting in improved project outcomes and financial savings.

Send your message to us

Tripod & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches