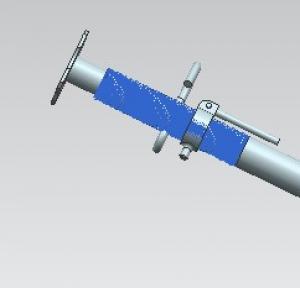

Painted Scaffolding Post Prop Support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000根 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ProducGerman,Spanish,Middle East prop, steel pipe surpport.

Adjustable height:0.8-5.5m

Pipe/Tube tickness:1.5mm-4mm

Innner Diameter:40mm,48mm,etc.

Outer Diameter:48mm,56mm,60mm,etc.

Plate type:square,flower/clover,U-head

Nut type: single handle(common,7-style, big 7-style),Cup-style/Double handle

Pin type:line stright with metal cap,line straight without metal cap,chain,G-style

Plate size:120*12*4mm,120*120*5mm,140*140*5mm/5.5mm,etc.

Surface treatment: painted,galvanized,powder coating

Color:orange,red,blue,green,white,etc.

OEM ACCEPTABLE

Fast delivery wihtin 30days

Professional and reliable

We are specilized in various kinds of steel props, the goods are in high quality and reasonable price.In case you are interested in our products, please do not hesitate to contact me.

- Q: Can steel props be used for supporting scaffolding systems?

- Yes, steel props can be used for supporting scaffolding systems. Steel props, also known as adjustable steel props or steel shore props, are commonly used in construction and scaffolding industries to provide temporary support to structures, such as scaffolding systems. These props are made of high-quality steel and have adjustable height features, allowing them to be easily set up and adjusted to the desired height for supporting the scaffolding system. Steel props are strong, durable, and capable of bearing heavy loads, making them a reliable choice for providing stability and support to scaffolding structures.

- Q: Can steel props be used in mining applications?

- Yes, steel props can be used in mining applications. Steel props, also known as steel supports or steel struts, are commonly used in underground mining operations to provide temporary or permanent support to the mine roof and walls. These props are made of high-quality steel and are designed to withstand the heavy loads and pressures associated with mining. Steel props are adjustable and can be set to the desired height and angle to support the mine roof and prevent collapses or cave-ins. They are versatile and can be used in various mining scenarios, including tunneling, shaft sinking, and longwall mining. Steel props are typically used in conjunction with other support systems, such as roof bolts, mesh, and shotcrete, to ensure the stability and safety of the mining operation. The use of steel props in mining applications offers several advantages. They are strong, durable, and resistant to corrosion, making them suitable for the harsh and demanding conditions of mining environments. Steel props are also easy to install, adjust, and remove, allowing for efficient and flexible support systems in mining operations. Additionally, steel props can be re-used, reducing costs and waste associated with support systems in mining. Overall, steel props are a reliable and effective solution for providing support in mining applications, contributing to the safety and productivity of underground mining operations.

- Q: Can steel props be used for supporting temporary seating arrangements?

- Temporary seating arrangements can be supported using steel props. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and building projects to provide support for temporary structures. They have the ability to be adjusted in height, making them versatile for various applications, including supporting temporary seating arrangements. Steel props offer a robust and stable support system that can handle heavy loads. Their height can be easily adjusted, allowing for flexibility when setting up temporary seating arrangements. Moreover, steel props are long-lasting and dependable, making them ideal for prolonged use. To ensure the safety and stability of temporary seating arrangements supported by steel props, it is crucial to correctly position and secure them. Adhering to safety guidelines and regulations is also essential to protect the well-being of individuals using the seating arrangements. Overall, steel props are a suitable choice for supporting temporary seating arrangements due to their strength, adjustability, and durability.

- Q: How do you inspect and certify steel props for safe use?

- To inspect and certify steel props for safe use, a thorough examination is conducted by trained professionals. This involves checking for any visible damage, such as bends, cracks, or deformities in the prop. Additionally, measurements are taken to verify its dimensions and ensure it meets the required specifications. Load testing may also be conducted to assess its load-bearing capacity. Once the inspection is complete and the prop meets all safety standards, it can be certified for safe use.

- Q: How are steel props transported to the construction site?

- Depending on their size and quantity, steel props are transported to the construction site using various methods. One way is through the utilization of flatbed trucks or trailers, where the props are firmly loaded onto the truck bed and secured with straps or chains to maintain stability while in transit. Alternatively, steel props may be transported in shipping containers for long-distance trips. In this method, the props are loaded and secured inside the container and then transported by road, rail, or sea. This approach safeguards the props from external factors and simplifies handling and loading/unloading at the construction site. For smaller quantities or shorter distances, smaller vehicles like pickup trucks or vans may be employed to transport the steel props. This is commonly done when the construction site is nearby or when urgent delivery is required. Irrespective of the transportation method chosen, it is crucial to ensure that the steel props are loaded, secured, and transported in a safe and lawful manner. Following transportation regulations and guidelines is essential in order to prevent accidents or damage during transit, guaranteeing that the steel props arrive at the construction site in excellent condition and ready for use.

- Q: Are steel props suitable for supporting temporary stages or platforms with moving parts?

- No, steel props may not be suitable for supporting temporary stages or platforms with moving parts. Steel props are typically used for providing vertical support and stability to structures like buildings or scaffolding. However, when it comes to stages or platforms with moving parts, such as those used in theatrical productions or concerts, more specialized and flexible support systems are usually required to accommodate the dynamic nature of these setups.

- Q: How do you store steel props when not in use?

- Steel props should be stored in a dry and well-ventilated area, preferably indoors, to prevent corrosion. They should be stacked on a flat surface, with a layer of wooden planks or rubber mats in between to avoid direct contact and potential damage. Additionally, it is advisable to apply a thin coat of rust-preventive oil or paint to the props before storage to further protect them from rusting.

- Q: Can steel props be used in seismic zones?

- Steel props can be used in seismic zones, but their use should be carefully evaluated and designed to ensure they can withstand the potential seismic forces. Steel props are commonly used in construction to support temporary structures or to provide additional support to existing structures during renovation or repair work. In seismic zones, where there is a higher risk of earthquakes, it is essential to consider the specific requirements and regulations related to seismic design. These requirements typically include factors such as the expected level of ground shaking, the building's location, the structural system, and the type of material used. Steel props can be designed to withstand seismic forces by considering factors such as their size, shape, material strength, and connection details. The design should take into account the expected seismic loads and incorporate appropriate safety factors to ensure the props can resist these forces without failure. In addition to proper design, it is also crucial to ensure that the installation and anchorage of steel props in seismic zones are carried out correctly. This may involve using specific techniques or additional reinforcement measures to enhance their stability and resistance to seismic forces. Ultimately, the use of steel props in seismic zones is possible, but it requires careful evaluation, design, and installation to ensure their effectiveness and safety. Consulting with structural engineers and adhering to local building codes and regulations is crucial to ensure that steel props are appropriately used in seismic-prone areas.

- Q: Are steel props reusable?

- Steel props, also known as adjustable steel props or steel shore, are temporary support structures used in construction projects to provide support and stability for formwork, scaffolding, and other temporary structures. These props are typically made from high-quality steel, which gives them strength and durability. They can be adjusted in height, making them versatile and suitable for various applications. To enhance their longevity, steel props are usually painted or coated to prevent rust and corrosion. Once used, steel props should be inspected for any damage or signs of wear and tear. If they are found to be in good condition, they can be cleaned, stored, and reused in future construction projects. However, it is important to note that the reusability of steel props may vary depending on factors such as the nature of the construction project, the load-bearing requirements, and the extent of wear and tear from previous use. To determine whether steel props are suitable for reuse, it is crucial to follow manufacturer guidelines, industry standards, and regulatory requirements. Proper maintenance and regular inspections are essential for ensuring the safety and performance of reused steel props.

- Q: How do steel props contribute to the overall quality of construction projects?

- Steel props contribute to the overall quality of construction projects by providing reliable and sturdy support for temporary structures, such as formwork and scaffolding. They help distribute the weight and load evenly, ensuring the stability and safety of the construction site. Additionally, steel props allow for easy adjustment and quick installation, improving efficiency and productivity during the construction process. Their durability and strength also enhance the longevity and structural integrity of the project, ultimately leading to a higher quality end result.

Send your message to us

Painted Scaffolding Post Prop Support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000根 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords