Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

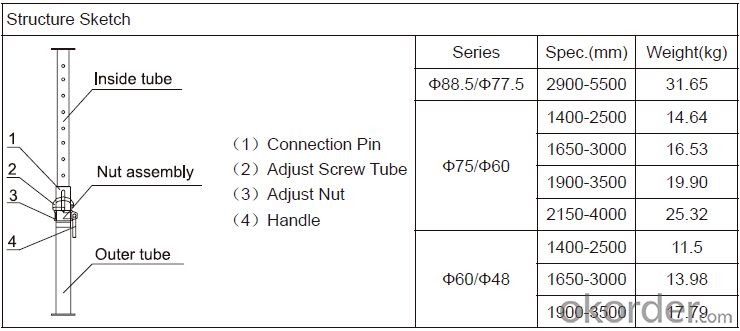

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

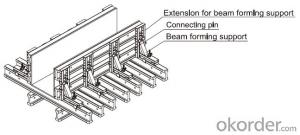

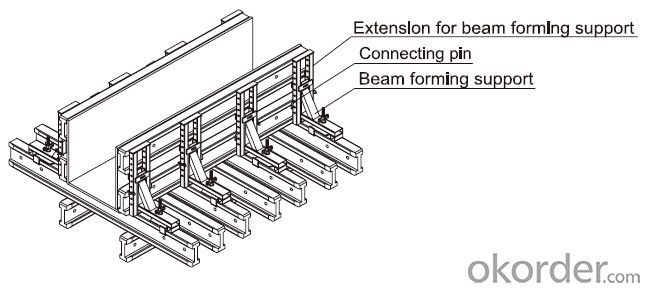

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used for temporary support during ductwork installation?

- Certainly! Temporary support during ductwork installation can be provided by steel props. These props, which are adjustable and sturdy, prove to be the perfect choice for holding ductwork firmly in place during installation. They can be effortlessly adjusted to the required height and securely locked into position, guaranteeing stability and safety for the ductwork. Moreover, steel props possess the ability to bear heavy loads, making them a suitable option for supporting the weight of ductwork along with any related equipment or materials. In summary, steel props present a dependable and pragmatic solution for temporary support during the installation of ductwork.

- Q: Are steel props suitable for temporary or permanent structures?

- Steel props are typically used for temporary structures such as formwork or scaffolding. While they can provide stability and support for temporary construction needs, they may not be suitable for permanent structures. For long-term or permanent structures, other construction methods and materials, such as concrete or steel frames, are commonly preferred for their durability and structural integrity.

- Q: What are the different sizes available for steel props?

- The sizes available for steel props can vary depending on the manufacturer and specific requirements of the project. However, commonly available sizes for steel props range from 1.8 meters to 5 meters in length, with adjustable heights typically ranging from 1.1 meters to 4 meters. These sizes provide flexibility and stability for a wide range of construction and support applications.

- Q: What is the installation spacing of the steel support of the tunnel 50mm

- The number of not less than the number of calculation of steel arch. For example, steel arch spacing design for 50cm, the first product installation distance is 55cm, when the second products will be changed to 45cm, so the cumulative calculation.

- Q: What is the average cost of a steel prop?

- There are multiple factors that influence the average price of a steel prop, including its size, quality, and brand. Currently, in the market, the cost per unit of a steel prop ranges from $30 to $100. It is crucial to consider that prices may vary depending on the region and suppliers you approach. Moreover, if you make bulk purchases or opt for rental options, there might be opportunities for discounts or reduced costs per unit. Hence, conducting thorough research and comparing prices from different sources is highly recommended to ascertain the precise average cost of a steel prop that aligns with your specific requirements.

- Q: Can steel props be used for supporting slabs and beams?

- Yes, steel props can be used for supporting slabs and beams. Steel props, also known as adjustable props or construction props, are devices used in construction to support temporary structures like formwork, slabs, beams, and columns. They are made of steel and are adjustable in height, allowing them to be used in various applications. Steel props are designed to provide temporary support and stability to structures during construction or renovation projects. They can be used to support slabs and beams of different sizes and weights. The adjustable feature allows for easy installation and customization to specific project requirements. The main advantage of using steel props is their strength and load-bearing capacity. They are capable of supporting heavy loads and provide a stable platform for construction work. Additionally, steel props are durable and can withstand harsh conditions on construction sites. It is important to note that steel props should be used in accordance with the manufacturer's guidelines and engineering specifications. Proper installation and regular inspection are necessary to ensure the safety and stability of the supported structures.

- Q: Can steel props be used in supporting temporary retaining walls?

- Yes, steel props can be used in supporting temporary retaining walls. Steel props are commonly used in construction projects to provide temporary support and stability to structures such as walls, beams, and floors. They are adjustable and can be easily installed, making them suitable for supporting temporary retaining walls. Steel props are designed to withstand heavy loads and provide the necessary support required for retaining walls. They are also versatile and can be used in various construction applications. However, it is essential to consult with a structural engineer or a construction professional to ensure that the steel props are appropriately sized and positioned to support the specific requirements of the temporary retaining wall.

- Q: Are steel props suitable for use in high-rise buildings?

- Yes, steel props are suitable for use in high-rise buildings. Steel props provide strong support and stability, making them ideal for supporting heavy loads and ensuring the structural integrity of tall buildings. They are adjustable in height, allowing for flexibility during construction and the ability to accommodate varying floor levels. Additionally, steel props are durable and resistant to fire, making them a reliable choice for high-rise construction projects.

- Q: Can steel props be used in the construction of wastewater treatment plants?

- Yes, steel props can be used in the construction of wastewater treatment plants. Steel props are commonly used in construction projects to support structures and provide temporary support during the construction process. In the case of wastewater treatment plants, steel props can be used to support various components such as tanks, pipelines, and equipment during installation. They provide stability and structural support, ensuring that the components are held securely in place. Additionally, steel props can also be used to support temporary structures like scaffolding, allowing workers to safely access different areas of the treatment plant during construction or maintenance activities. Overall, steel props are a versatile and reliable option for supporting various elements of wastewater treatment plant construction.

- Q: In the construction of the cast-in-place floor of the fastener type steel pipe support system, which belongs to the full scaffold, or belong to the template and support system

- The calculation rules of the formwork support system of the cast in place beam and slab structure and the construction load of the full scaffold are different.

Send your message to us

Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches