Steel Prop & Tripod & Beam Clamp for Build

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

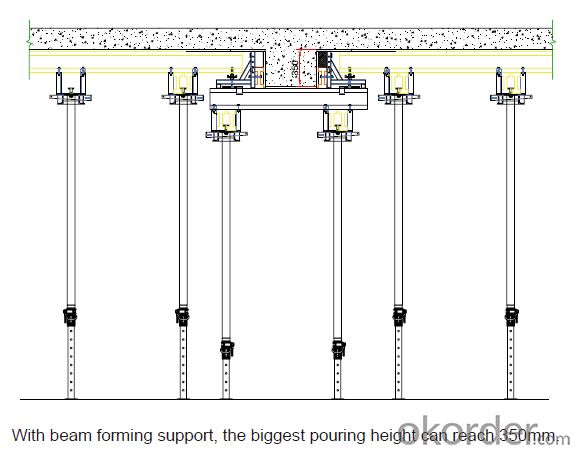

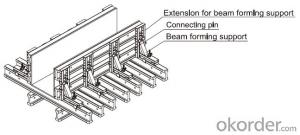

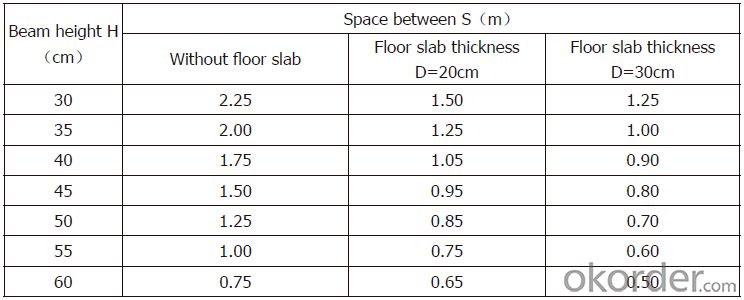

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Are steel props suitable for use in the construction of theaters?

- Yes, steel props are commonly used in the construction of theaters due to their durability, strength, and stability. They provide necessary support for stage sets, backdrops, and lighting equipment, ensuring the safety and structural integrity of the theater.

- Q: Are steel props adjustable on uneven surfaces?

- Yes, steel props are adjustable on uneven surfaces. They are designed to have telescopic sections that can be extended or retracted to accommodate different heights and levels of unevenness. This adjustability helps provide stability and support in various construction or temporary support applications.

- Q: What are the advantages of using a steel prop?

- There are several advantages of using a steel prop. Firstly, steel props are incredibly strong and durable, making them suitable for supporting heavy loads and providing stability during construction or renovation projects. Additionally, steel props are adjustable, allowing for easy customization and precise positioning as per the requirements of the job. They are also resistant to fire and corrosion, ensuring their longevity and reliability in various environments. Lastly, steel props are lightweight and easy to handle, making them convenient for transportation and installation on-site.

- Q: Can steel props be used in different construction applications?

- Various construction applications can utilize steel props, which are also known as adjustable steel props or steel shores. These versatile support systems are commonly employed in construction to provide temporary support during projects involving beams, walls, and ceilings. Steel props can be adjusted in height to accommodate different construction needs. They can be employed to support formwork while concrete is poured, offer temporary support to walls or beams during demolition or renovation, or even serve as temporary supports for pre-existing structures during repair or reinforcement. The robustness and durability of steel props make them suitable for a wide range of construction applications. They possess the ability to withstand heavy loads and can be easily adjusted to the desired height, ensuring stability and safety at the construction site. Moreover, steel props offer several advantages, including ease of installation, reusability, and versatility. They can be installed, adjusted, and removed quickly and effortlessly, resulting in time and labor savings. Additionally, their reusability makes them a cost-effective solution for multiple construction projects. In conclusion, steel props are indeed applicable to diverse construction scenarios due to their adjustable height, strength, durability, and versatility. They play a crucial role in providing temporary support and stability during construction or renovation projects, making them an indispensable tool for professionals in the construction industry.

- Q: How do steel props affect the construction schedule?

- Steel props, also known as steel shoring or steel supports, play a vital role in construction and can greatly affect the construction timeline. These temporary structural elements are utilized to bear loads during construction or renovation endeavors. The construction schedule is greatly influenced by steel props due to their ability to provide stability and support to the structure. This allows workers to safely undertake various tasks, including concrete pouring, beam installation, and demolition work. Without the presence of steel props, construction activities may be postponed or even halted due to safety concerns. Furthermore, steel props promote smooth progress in construction projects by offering additional support during critical stages. For instance, when erecting tall buildings or structures with wide spans, steel props can bear the weight of the structure until permanent supports like columns or beams are put in place. This enables construction to continue without delays, eliminating the need to wait for the completion of permanent structural elements. Moreover, steel props contribute to expedited construction by providing a means of supporting formwork or falsework. Formwork is utilized to shape and structure concrete elements, such as walls or slabs. Steel props hold the formwork in position while the concrete solidifies, allowing for swift removal and repositioning of formwork for subsequent stages. This expedites the construction process and reduces the overall project duration. However, it is important to note that the impact of steel props on the construction schedule can be influenced by various factors. These factors include the quantity and size of required props, their placement, and the complexity of the construction project. In certain cases, delays may occur if adjustments or modifications to the props are necessary due to design changes or unforeseen circumstances. In conclusion, steel props have a significant impact on the construction schedule by providing stability, support, and acceleration to the construction process. Their utilization ensures worker safety, enables the progression of critical stages, and allows for faster completion of construction projects.

- Q: What are the typical diameters of steel props?

- The typical diameters of steel props vary depending on the specific application and load requirements. However, in general, steel props typically have diameters ranging from 40mm to 60mm. These diameters are chosen to provide sufficient strength and stability to support heavy loads and ensure the safety of the construction site. It is important to note that the diameter of steel props can also be customized based on specific project needs and requirements.

- Q: Can steel props be used for scaffolding purposes?

- Indeed, steel props have the capacity to serve as scaffolding aids. Referred to as adjustable props or steel acrow props, these sturdy steel devices are frequently employed in construction and building endeavors to bolster and ensure the stability of provisional structures, such as scaffolding. Constructed from resilient steel materials, they possess the ability to withstand substantial loads and furnish a solid foundation for scaffolding. Notably, these steel props can be flexibly modified to accommodate different heights, and their installation and disassembly processes are straightforward, rendering them a dependable and effective option for scaffolding applications.

- Q: How do you ensure proper communication between different work teams using steel props?

- To ensure proper communication between different work teams using steel props, the following strategies can be employed: 1. Clear communication channels should be established, allowing teams to effectively communicate. This may involve utilizing tools such as email, project management software, or instant messaging platforms. 2. Regular team meetings should be encouraged to discuss progress, challenges, and relevant updates. Such meetings facilitate communication and collaboration among different teams, ensuring everyone is informed and aligned. 3. A dedicated communication coordinator can be assigned to facilitate effective communication between teams. This individual acts as a liaison, ensuring timely and accurate flow of communication. 4. A culture of open communication should be fostered, where team members are encouraged to voice their thoughts, ask questions, and share ideas. Creating an environment where everyone feels comfortable expressing themselves enhances communication between teams. 5. Visual aids and documentation can be utilized to enhance understanding and communication. Charts, diagrams, and project timelines can assist in conveying information, while documenting important decisions and progress updates in a shared location ensures everyone is informed. 6. Regular team-building activities can be organized to improve relationships and communication between work teams. These activities may include workshops, retreats, or team-building exercises that encourage collaboration and interpersonal communication. 7. Training sessions and workshops on effective communication techniques and tools should be provided to team members. Offering resources and support empowers individuals to communicate more effectively within and across teams. 8. A collaborative work environment should be fostered, providing opportunities for teams to work together on projects or initiatives. This promotes better understanding and communication between different work teams. 9. Feedback should be actively encouraged, and continuous improvement should be sought. Regularly seeking feedback from team members on communication processes and implementing improvements based on suggestions ensures ongoing improvement in communication practices. By implementing these strategies, proper communication between different work teams using steel props can be ensured, leading to improved coordination, productivity, and overall project success.

- Q: Are steel props suitable for supporting temporary stairs or ramps?

- Yes, steel props are suitable for supporting temporary stairs or ramps. Steel props are adjustable telescopic supports that are commonly used in construction to provide temporary support to structures. They are designed to be versatile and can be adjusted to the desired height and angle, making them ideal for supporting temporary stairs or ramps. Steel props are known for their strength and stability, which makes them capable of carrying heavy loads. They are made from high-quality steel, which ensures their durability and reliability. Moreover, steel props are designed with safety features such as locking pins or collars to prevent accidental collapse or movement. When it comes to supporting temporary stairs or ramps, steel props provide a solid and secure base. They can be easily positioned and adjusted to the required height and angle, ensuring that the stairs or ramps are level and stable. This is particularly important for ensuring the safety of individuals using the stairs or ramps. Additionally, steel props can be easily installed and dismantled, making them highly convenient for temporary structures. They can be quickly adjusted or removed as needed, allowing for easy reconfiguration or relocation of the stairs or ramps. Overall, steel props are a suitable choice for supporting temporary stairs or ramps due to their strength, stability, versatility, and ease of use. They provide a secure and reliable solution for temporary structural support, ensuring the safety and functionality of stairs or ramps.

- Q: In the construction of the cast-in-place floor of the fastener type steel pipe support system, which belongs to the full scaffold, or belong to the template and support system

- For concrete beams, plates and other cast members, in the construction process in the template side with steel pipe and fastener as template support, not full scaffold and belongs to the template and support system.

Send your message to us

Steel Prop & Tripod & Beam Clamp for Build

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords