Steel prop & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used for supporting temporary walkways or ramps?

- Yes, steel props can be used for supporting temporary walkways or ramps. Steel props, also known as adjustable steel props or steel acrow props, are commonly used in construction projects to support structures and provide temporary bracing. They are designed to provide stability and load-bearing capacity, making them suitable for supporting walkways or ramps. Steel props are adjustable in height, allowing them to be set at the desired level to support the temporary structure. They come in various sizes and weight capacities, making it easy to choose the appropriate prop for the specific application. Additionally, steel props are made from strong and durable materials, ensuring their ability to withstand the weight and pressure exerted by individuals walking or using ramps. When using steel props for supporting temporary walkways or ramps, it is important to ensure proper installation and adherence to safety guidelines. The props should be securely placed and evenly distributed to provide a stable and even surface. Regular inspections and maintenance should also be conducted to ensure the props remain in good condition and continue to provide adequate support. Overall, steel props are a reliable and effective option for supporting temporary walkways or ramps, offering the necessary strength and stability required for safe usage.

- Q: Can steel props be used for temporary support in offshore pipeline installation?

- Yes, steel props can be used for temporary support in offshore pipeline installation. Steel props are commonly used in construction and offshore projects to provide temporary support and stability during various stages of installation. They are strong, durable, and able to withstand the harsh conditions of the offshore environment, making them suitable for supporting pipelines during installation.

- Q: Can steel props be used in the construction of dams?

- Yes, steel props can be used in the construction of dams. Steel props, also known as steel supports or steel shoring, are commonly used in construction projects to provide temporary support to structures or excavations. In dam construction, steel props can be utilized during various stages of the project. During the excavation phase, steel props can be used to secure the sides of the excavation and prevent soil or rock collapse. This is crucial to ensure the safety of workers and maintain the stability of the site. Steel props can be adjusted and installed at different lengths to accommodate the specific requirements of the excavation. Additionally, steel props can also be used during the construction of the dam walls. They can be employed to support the formwork or molds used to shape the concrete walls of the dam. Steel props provide stability and strength to the formwork, allowing construction workers to pour and shape the concrete in a controlled manner. Moreover, steel props can be utilized during the maintenance or repair of dams. When certain sections of a dam need to be accessed for maintenance or repair work, steel props can be used to provide temporary support to the surrounding structures. This ensures the safety of workers and prevents any potential collapse or damage to the dam. Overall, steel props are versatile and reliable tools that can be effectively used in the construction of dams. They provide temporary support, stability, and safety, making them an essential component in the construction and maintenance of dams.

- Q: Can steel props be used in renovation projects?

- Yes, steel props can be used in renovation projects. Steel props are adjustable and sturdy support structures that can provide temporary support to walls, ceilings, or other structures during renovation work. They are commonly used to ensure safety and stability during the renovation process, especially when load-bearing walls are removed or modified. Steel props are versatile and can be easily adjusted to different heights, making them suitable for various renovation projects.

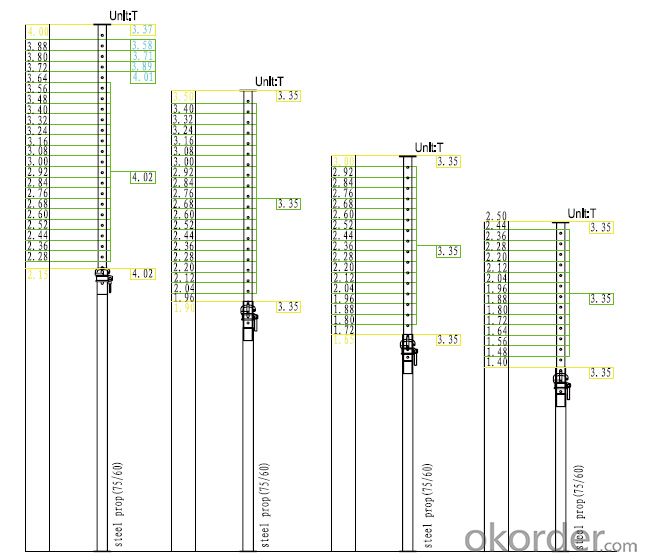

- Q: What are the different sizes and weight capacities available for steel props?

- Steel props, also known as adjustable steel props or steel acrow props, come in various sizes and weight capacities to cater to different construction and support needs. The sizes and weight capacities available for steel props can vary depending on the manufacturer and supplier, but generally, they can be categorized as follows: 1. Mini Steel Props: These are the smallest and most lightweight props, usually used for light-duty applications or in confined spaces. They have a smaller size and lower weight capacity, typically ranging from 0.6 meters to 1.2 meters in height and supporting loads up to around 1 ton. 2. Standard Steel Props: These are the most commonly used steel props, suitable for a wide range of construction projects. They have a moderate size and weight capacity, usually ranging from 1.8 meters to 5 meters in height and supporting loads up to several tons, typically between 2 to 5 tons. 3. Heavy-Duty Steel Props: These props are designed for heavy-duty applications where higher load-bearing capacity is required. They are larger and stronger than standard props, typically ranging from 3 meters to 6 meters in height and supporting loads up to 10 tons or more. It is important to note that these sizes and weight capacities are approximate and can vary depending on the specific manufacturer and model. Additionally, steel props are often adjustable in height, allowing for flexibility in various construction scenarios. The weight capacity of steel props is usually mentioned by the manufacturer and should be strictly adhered to ensure safety and stability during use. Overall, the availability of different sizes and weight capacities for steel props allows construction professionals to choose the most suitable props for their specific project requirements, ensuring proper support and stability during construction activities.

- Q: Can steel props be used in the construction of manufacturing facilities?

- Yes, steel props can be used in the construction of manufacturing facilities. Steel props, also known as steel shores or acrow props, are adjustable supports that are commonly used in construction to provide temporary support during the building process. They are made of steel and have a telescopic design, allowing them to be adjusted to the required height. In the construction of manufacturing facilities, steel props can be used in various ways. One of the main applications is to support formwork or scaffolding systems. Formwork is used to create the molds or frames for pouring concrete, while scaffolding is used to provide a safe working platform for workers. Steel props are used to provide additional support to these structures, ensuring stability and safety during the construction process. Steel props can also be used to support heavy loads or equipment during the installation phase. Manufacturing facilities often require the installation of heavy machinery, equipment, or production lines. Steel props can be used to provide temporary support while these installations are being carried out, ensuring that the load is properly distributed and preventing any potential accidents or damages. Furthermore, steel props can be used to support temporary structures such as mezzanines, walkways, or platforms. These structures are commonly used in manufacturing facilities to maximize space utilization and create additional working areas. Steel props provide the necessary support to ensure the stability and safety of these temporary structures. Overall, steel props are versatile and reliable temporary support systems that can be used in the construction of manufacturing facilities. They play a crucial role in ensuring the stability, safety, and efficiency of the construction process, making them an essential component in the successful completion of manufacturing facility projects.

- Q: Can steel props be used for supporting temporary amusement park rides or attractions?

- Yes, steel props can be used for supporting temporary amusement park rides or attractions. Steel props are commonly used in construction and engineering projects to provide temporary support for structures. They are sturdy, durable, and can bear heavy loads, making them suitable for supporting amusement park rides or attractions. However, it is essential to ensure that the steel props are properly designed, installed, and maintained to ensure the safety of the rides and the people using them. Regular inspections should also be conducted to identify any signs of wear, damage, or instability in the steel props and address them promptly to ensure the continued safety of the temporary amusement park rides or attractions.

- Q: How do you determine the required number of steel props for a project?

- The required number of steel props for a project is determined by assessing the load-bearing capacity of the structure, the span of the area being supported, and the spacing between the props. Additionally, factors such as the type of construction, the weight of materials being used, and the height of the structure must also be considered. Engineering calculations and consultation with structural experts are essential in determining the appropriate number of steel props to ensure the safety and stability of the project.

- Q: Are there any limitations to using steel props?

- Yes, there are some limitations to using steel props. Firstly, steel props have a limited load-bearing capacity, which means they may not be suitable for supporting extremely heavy loads. Additionally, steel props are not adjustable in height, so they may not be suitable for projects that require frequent changes in height requirements. Finally, steel props can be quite heavy and bulky, making them difficult to transport and maneuver in some situations.

- Q: How do you ensure proper stability when using steel props on sloping ground?

- To ensure proper stability when using steel props on sloping ground, there are several measures that can be taken: 1. Assess the ground conditions: Before starting the installation of steel props, it is crucial to assess the ground conditions thoroughly. Conduct a comprehensive survey of the soil type, its stability, and any potential risks such as loose or erodible material. 2. Choose the right prop size and design: Selecting the appropriate size and design of the steel props is essential. Ensure that the props have sufficient load-bearing capacity and are suitable for the specific ground conditions and slope angle. Consult with a structural engineer or an expert to determine the most suitable props for the job. 3. Proper installation: When installing the steel props, it is crucial to follow the manufacturer's guidelines and recommendations. Install the props securely and ensure that they are properly aligned and supported. Use shoring plates or timber wedges to level and stabilize the props on the sloping ground. 4. Brace the props: To enhance stability, consider bracing the steel props. Bracing helps distribute the load and prevent lateral movement, especially on sloping ground. Use diagonal braces or tiebacks to connect the props securely to a stable structure or anchor points. This will provide additional support and stability. 5. Regular monitoring and maintenance: Once the steel props are in place, it is essential to monitor them regularly for any signs of movement, settlement, or instability. Inspect the props and the surrounding ground periodically throughout the project to ensure they remain secure. If any issues are identified, take immediate action to rectify them. 6. Seek professional advice: If you are unsure about the stability or safety of using steel props on sloping ground, it is always better to seek professional advice. Consulting with a structural engineer or a qualified professional will help ensure that the proper measures are taken to guarantee stability and safety. By following these steps, you can ensure proper stability when using steel props on sloping ground, minimizing the risk of accidents, collapses, or damage to the structure being supported.

Send your message to us

Steel prop & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords