Steel Prop & Tripod for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

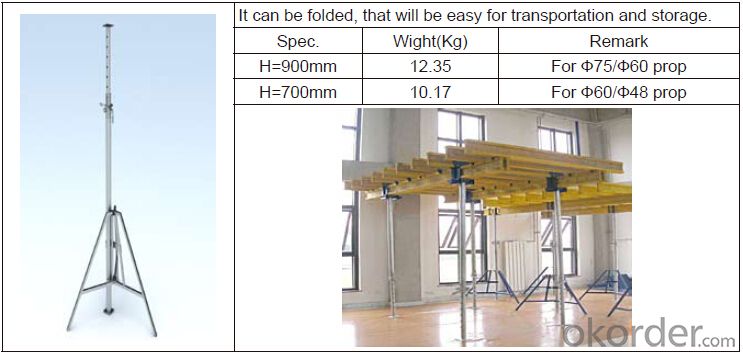

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

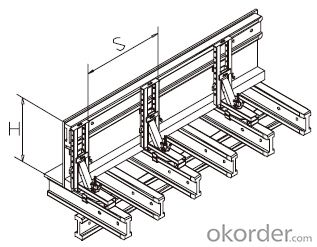

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Are steel props adjustable for supporting structures with irregular shapes?

- Indeed, steel props possess an adjustable nature, rendering them capable of providing support for structures of irregular configurations. With their ability to be modified to various heights, steel props prove to be highly adaptable, making them ideal for bolstering structures of diverse sizes and shapes. The adjustable attribute further enables the props to expand or contract as per the distinct demands of the irregular shape. This flexibility greatly contributes to the widespread preference for steel props in construction endeavors wherein the structure's shape may deviate from the conventional or uniform.

- Q: How do you calculate the required height for a steel prop?

- To calculate the required height for a steel prop, you need to consider the load that the prop will be supporting. The height of the prop is determined by the distance between the load and the ground, as well as the weight of the load. First, determine the weight of the load that the prop will be supporting. This could be the weight of a structure, such as a beam or slab, or the weight of construction equipment or materials. Next, calculate the distance between the load and the ground. This is typically measured vertically, but if there are any angles involved, you may need to use trigonometry to determine the vertical height. Once you have the weight of the load and the distance to the ground, you can use engineering principles to calculate the required height for the steel prop. This calculation typically involves determining the load-bearing capacity of the prop, which is a measure of how much weight it can safely support. The load-bearing capacity can be obtained from manufacturer specifications or engineering design tables. Divide the weight of the load by the load-bearing capacity of the prop to determine the number of props required. Then, divide the distance to the ground by the number of props to determine the required height for each individual prop. It is important to note that these calculations are based on engineering principles and safety factors should be considered. It is always recommended to consult with a structural engineer or other qualified professional to ensure that the calculations are accurate and that the steel prop will be able to safely support the load.

- Q: How do steel props contribute to the prevention of structural deformations?

- Steel props contribute to the prevention of structural deformations by providing temporary support during construction or repair work. These props are adjustable and can be positioned under beams, slabs, or walls to transfer the load and provide stability. By evenly distributing the weight and preventing excessive deflection, steel props help maintain the structural integrity of a building, ensuring it remains safe and stable during construction or renovation.

- Q: Can steel props be used in supporting temporary playground equipment?

- Certainly! Temporary playground equipment can indeed be supported using steel props. In construction and engineering, steel props are frequently employed to offer temporary support to structures. Due to their strength, durability, and ability to bear heavy loads, they are well-suited for supporting playground equipment. However, it is crucial to guarantee the proper installation and anchoring of the steel props, as well as their compliance with essential safety standards, in order to prevent any accidents or injuries. Additionally, regular inspections and maintenance are necessary to ensure the safety and stability of the playground equipment.

- Q: Can steel props be used in the installation of temporary water or sewage pipelines?

- Yes, steel props can be used in the installation of temporary water or sewage pipelines. Steel props are commonly used in construction projects to provide support and stability to structures during installation or repair work. In the case of temporary water or sewage pipelines, steel props can be used to hold the pipelines in place and prevent them from collapsing or shifting. Steel props are sturdy and can withstand the weight and pressure exerted by the pipelines. Additionally, they are adjustable in height and can be easily installed and removed, making them suitable for temporary installations. Overall, steel props are a reliable and effective solution for ensuring the proper installation and stability of temporary water or sewage pipelines.

- Q: How do you ensure stability when using steel props on uneven surfaces?

- When using steel props on uneven surfaces, there are a few measures you can take to ensure stability. Firstly, it is crucial to properly assess the ground conditions before placing the steel props. Identify any unevenness or irregularities in the surface and make necessary adjustments to level it out as much as possible. This can involve removing debris or filling in gaps with compacted soil or gravel. Secondly, consider using adjustable props that have the capability to adapt to uneven surfaces. These props usually have telescopic sections that can be extended or retracted to match the height requirements and compensate for any irregularities. By adjusting the props accordingly, you can achieve a stable and secure setup. Furthermore, it is advisable to use a base plate or a suitable load-bearing platform underneath the steel props. This helps distribute the load evenly and provides a larger surface area, reducing the risk of sinking or tilting. Ensure that the base plate or platform is level and securely positioned, taking into account the weight and size of the props being used. Additionally, when setting up steel props on uneven surfaces, it is essential to provide adequate bracing and support. Bracing can be achieved by using diagonal struts or cross braces to reinforce the structure and prevent lateral movement. This helps to maintain stability and prevent any potential collapse or displacement. Regular monitoring and inspection of the props during use is also crucial. Perform regular checks to ensure that the props remain secure and stable, adjusting them as needed. Any signs of instability or movement should be promptly addressed and rectified to ensure the safety of the structure and personnel working in the vicinity. Lastly, it is always wise to consult with a professional engineer or seek expert advice when working with steel props on uneven surfaces. They can provide guidance and recommendations specific to your project requirements, ensuring that stability is maintained and potential risks are minimized.

- Q: Can steel props be used for temporary support during machinery installation?

- Yes, steel props can be used for temporary support during machinery installation. Steel props are typically adjustable and can be extended to reach the desired height to support the machinery. They are strong and sturdy, making them suitable for providing temporary support during installation. Additionally, steel props are designed to withstand heavy loads, making them reliable for supporting the weight of machinery during the installation process. However, it is important to ensure that the steel props are properly installed and secured to prevent any accidents or instability. It is also recommended to consult with professionals or engineers to determine the appropriate size and type of steel props required for the specific machinery installation.

- Q: Can steel props be used for temporary support in bridge maintenance work?

- Yes, steel props can be used for temporary support in bridge maintenance work. Steel props provide strong and reliable support, making them suitable for various construction and maintenance applications, including bridge maintenance. They can help distribute the load, maintain stability, and ensure safety during maintenance operations.

- Q: Can steel props be used in supporting temporary signage and banners?

- Yes, steel props can be used to support temporary signage and banners. Steel props are strong, durable, and provide stability, making them suitable for holding up larger and heavier signage and banners. They offer reliable support and can be easily adjusted to the desired height and angle.

- Q: Are steel props suitable for use in bridge construction?

- Yes, steel props are suitable for use in bridge construction. Steel props, also known as adjustable steel props or steel shores, are commonly used in construction projects to support structures and provide temporary load-bearing support. In bridge construction, steel props play a crucial role in providing stability and reinforcement during various stages of the project. Steel props are made of high-quality steel, ensuring their durability and strength. They are adjustable, allowing for easy customization based on the specific requirements of the bridge construction project. This adjustability enables the props to accommodate different loads and heights, making them versatile and adaptable. One of the main advantages of using steel props in bridge construction is their load-bearing capacity. Steel props can support heavy loads and distribute the weight effectively, ensuring the stability and safety of the bridge structure. They can withstand high-pressure forces and provide the necessary reinforcement during different phases of construction, such as formwork, concrete pouring, and beam installation. Additionally, steel props are relatively lightweight, which makes them easier to handle and transport on the construction site. Their modular design allows for quick assembly and disassembly, saving time and labor costs. Moreover, steel props are reusable, making them a cost-effective solution for bridge construction projects. Overall, steel props offer several advantages that make them suitable for use in bridge construction. Their strength, adaptability, load-bearing capacity, and cost-effectiveness make them a reliable choice for providing temporary support and reinforcement during the construction of bridges.

Send your message to us

Steel Prop & Tripod for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords