Steel Prop & Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

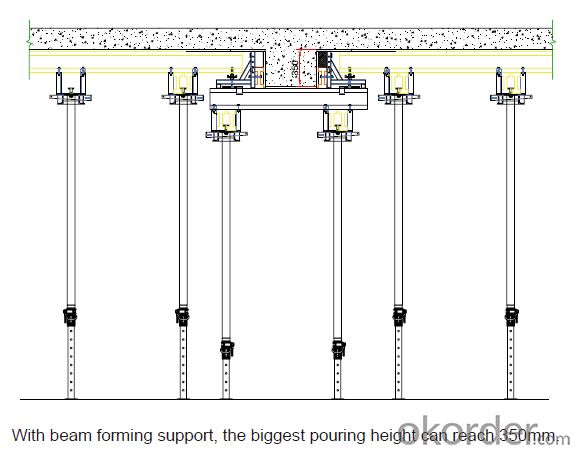

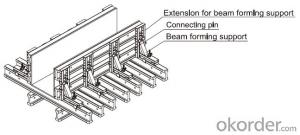

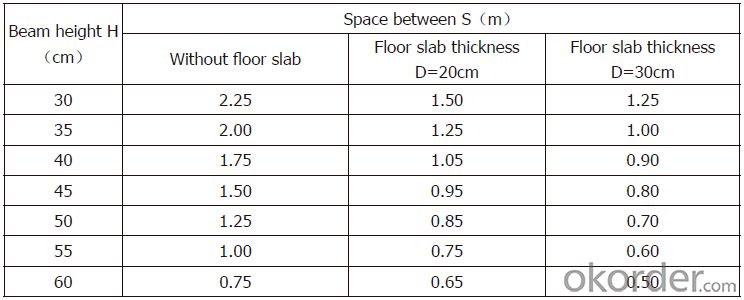

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used for supporting temporary storage structures or warehouses?

- Yes, steel props can be used for supporting temporary storage structures or warehouses. Steel props, also known as adjustable steel props or scaffolding props, are commonly used in the construction industry to provide temporary support to structures. They are made of high-quality steel and have the ability to withstand heavy loads. Steel props are adjustable in height, making them suitable for various applications, including supporting temporary storage structures or warehouses. They are easy to set up and dismantle, providing a flexible and efficient solution for temporary storage needs. Additionally, steel props offer stability and durability, ensuring the safety and security of the storage structure or warehouse.

- Q: Why are steel braces less concrete?

- The concrete and the waist beam expansion coefficient almost, steel and steel purlin expansion coefficient is very similar, so more stable and safe.

- Q: Do steel props comply with building codes and regulations?

- Yes, steel props comply with building codes and regulations. They are commonly used in construction projects as temporary supports for various structural elements, such as floors, walls, and beams. Steel props are designed and manufactured to meet specific load-bearing requirements and safety standards outlined in building codes and regulations. They undergo rigorous testing and are certified to ensure their reliability and compliance with these standards.

- Q: What are the alternatives to using steel props?

- There are several alternatives to using steel props in construction and supporting structures. Some of the commonly used alternatives include: 1. Aluminum Props: Aluminum props are lightweight and easy to handle, making them a popular choice for temporary support in construction projects. They offer high load-bearing capacity and can be adjusted to different heights. Additionally, aluminum props are resistant to corrosion, making them suitable for outdoor use. 2. Timber Props: Timber props, also known as wooden props, are a traditional alternative to steel props. They are cost-effective, readily available, and easy to install. Timber props are often used in smaller construction projects or where temporary support is required. However, they may not offer the same load-bearing capacity as steel props. 3. Adjustable Telescopic Props: These props are made of a combination of materials such as aluminum, timber, or composite materials. They consist of extendable sections that can be adjusted to different heights, offering versatility in various construction applications. Adjustable telescopic props are lightweight, easy to handle, and provide reliable support. 4. Hydraulic Props: Hydraulic props use hydraulic pressure to provide support. They are typically used in mining operations or situations where heavy loads need to be supported. Hydraulic props offer the advantage of being able to withstand high loads and can be easily adjusted for height. However, they require specialized equipment and skilled operators to operate effectively. 5. Composite Props: Composite props are made from a combination of materials such as fiberglass, carbon fiber, or reinforced polymers. They offer high strength-to-weight ratios, making them ideal for applications where lightweight support is required. Composite props are resistant to corrosion and can withstand heavy loads, but they may be more expensive than other alternatives. It is important to consider the specific requirements of the project, such as load capacity, duration of support, and environmental conditions, when choosing an alternative to steel props. Consulting with a structural engineer or construction professional can help in selecting the most suitable alternative for a particular project.

- Q: Are steel props suitable for supporting temporary grandstands or bleachers at sporting events?

- Absolutely, steel props are a great choice for providing support to temporary grandstands or bleachers during sporting events. Steel, being an incredibly robust and long-lasting material, can effortlessly withstand the immense weight and pressure exerted by numerous spectators occupying the grandstands or bleachers. Its stability guarantees the safety of the audience throughout the event. Widely utilized in construction and engineering ventures, steel props are specifically engineered to bear substantial loads. Additionally, they can be conveniently adjusted and installed to cater to the precise demands of temporary grandstands or bleachers. Consequently, they serve as an optimal selection for bolstering these structures at sporting events.

- Q: Can steel props be used in hospital construction?

- Indeed, hospital construction can make use of steel props. These props, also known as adjustable steel props or steel shoring props, are commonly utilized in construction projects to temporarily support structures. They possess versatility, as they can be adjusted to different heights, making them suitable for a variety of applications in hospital construction. Within the realm of hospital construction, steel props can serve various purposes. They offer support to ceilings, walls, and beams throughout the construction process. Furthermore, steel props can provide assistance to temporary structures like scaffolding or formwork, which are crucial for construction activities. In addition, steel props are recognized for their strength and stability, rendering them a dependable choice for hospital construction. Hospitals necessitate structures that can withstand heavy loads and ensure a safe environment for patients and staff. Steel props, crafted from high-quality steel, provide the requisite strength and stability demanded by critical infrastructure projects such as hospitals. Furthermore, steel props are adjustable, facilitating easy installation and adaptation to changing construction needs. Hospital construction often involves intricate designs and layouts, and steel props can be effortlessly adjusted to different heights and angles to accommodate these requirements. Moreover, steel props exhibit durability and longevity, resulting in a cost-effective solution for hospital construction. Hospitals represent long-term investments, and employing steel props guarantees the longevity and stability of the structures, reducing the need for frequent repairs or replacements. In conclusion, steel props can undoubtedly find utility in hospital construction. Their strength, stability, adjustability, and durability make them an ideal choice for supporting various structures during the construction process.

- Q: Basement slab reinforcement drawings did not explain how to calculate the final accounts?

- Is only part of the sample was not standard, still construction

- Q: How do steel props compare to steel beams?

- Steel props and steel beams are two different structural elements used in construction. Steel props, also known as adjustable steel props or acrow props, are temporary supports designed to provide vertical support during construction or renovation projects. They are typically used to support formwork, scaffolding, or any temporary load-bearing structures. On the other hand, steel beams are permanent structural elements that provide horizontal support and load-bearing capacity in buildings or bridges. Steel beams are designed to bear heavy loads and distribute them evenly across their length. In comparison, steel props and steel beams serve different purposes in construction. Steel props are adjustable and temporary, allowing for easy installation, removal, and adjustments as per the construction requirements. They are primarily used for vertical support and temporary load-bearing applications. In contrast, steel beams are designed for long-term structural support and can bear heavy loads over extended spans. They provide horizontal support and structural stability to buildings or bridges. Steel beams are typically integrated into the permanent structure and play a crucial role in distributing loads and maintaining the overall integrity of the construction. Overall, steel props and steel beams have distinct functions and are used in different contexts within the construction industry. While steel props offer temporary vertical support, steel beams provide long-term horizontal support and load-bearing capacity in permanent structures.

- Q: What is the typical lifespan of a steel prop?

- The typical lifespan of a steel prop can vary depending on various factors such as usage, load capacity, maintenance, and environmental conditions. However, on average, a well-maintained steel prop can last for around 10 to 15 years.

- Q: What is the maximum lateral load that a steel prop can withstand?

- The maximum lateral load that a steel prop can withstand depends on various factors such as the specific type and size of the prop, its design and construction, as well as the conditions and environment in which it is being used. It is essential to refer to the manufacturer's specifications and guidelines for accurate information regarding the maximum lateral load capacity of a particular steel prop.

Send your message to us

Steel Prop & Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords