Steel Prop & Tripod & Beam Clamp For Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

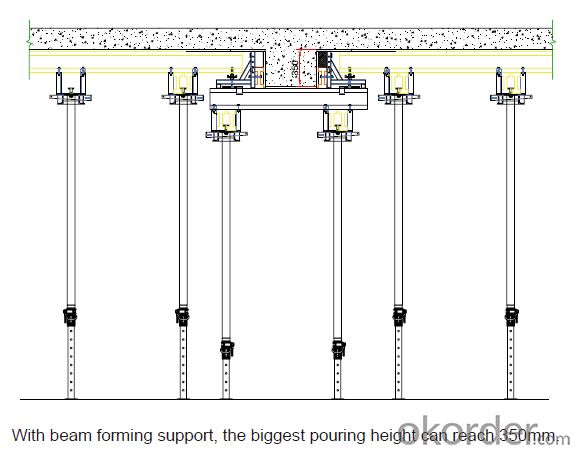

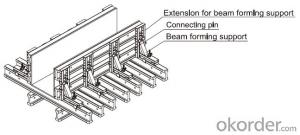

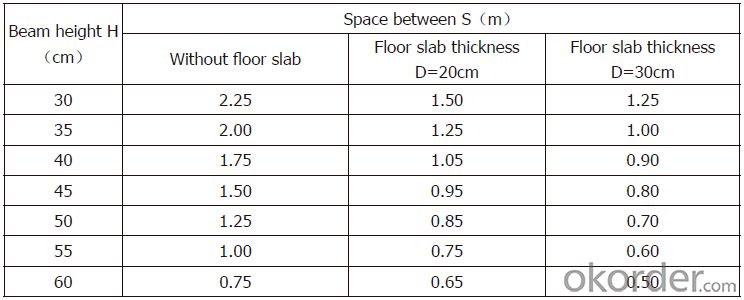

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Steel pipe support column in the vertical direction of the pressure, how to calculate the size of the deflection?

- Pressure does not consider the degree of tension, consider the amount of compressionIf it is to do the program, according to the constraint conditions of the bar, check the stability, as if there is a coefficient of what it is

- Q: Can steel props be used to support heavy machinery?

- Yes, steel props can be used to support heavy machinery. Steel props are sturdy and durable, making them suitable for providing strong support to heavy loads.

- Q: What are the common causes of failure of steel props?

- There are several common causes of failure of steel props, which are temporary support structures used in construction projects. These causes can be categorized into three main factors: design, material, and usage. Firstly, design flaws can contribute to the failure of steel props. Inadequate design calculations, such as underestimating the load-bearing capacity or the height required for the prop, can lead to structural failure. Insufficient bracing or improper placement of props can also result in instability and collapse. Therefore, it is crucial to ensure that the design of steel props is thorough, taking into account the specific requirements and conditions of the construction project. Secondly, the quality and material of the steel props themselves can play a significant role in their failure. Poor quality materials or manufacturing defects can weaken the structural integrity of the props, making them more susceptible to failure. For instance, if the steel used in the props is of low quality or has not been properly treated or coated for corrosion resistance, it may lead to premature deterioration and subsequent failure. Regular inspections and maintenance are essential to identify any potential material-related issues and prevent failures. Lastly, improper usage and handling of steel props can also contribute to their failure. Overloading the props beyond their rated capacity is a common cause of failure. This can occur when contractors or workers fail to follow the guidelines and specifications provided by the manufacturer. Additionally, mishandling during transportation, assembly, or disassembly can lead to damage or misalignment of the props, compromising their structural integrity and potentially causing failure. To mitigate the risk of failure, it is essential to ensure proper design, use high-quality materials, and follow the manufacturer's guidelines for installation and usage. Regular inspections, maintenance, and training of construction workers on proper handling and usage techniques are also crucial to prevent the failure of steel props.

- Q: Are steel props suitable for use in offshore wind farm construction?

- Yes, steel props are suitable for use in offshore wind farm construction. Steel props are commonly used in construction projects, including offshore wind farms, due to their strength, durability, and versatility. Offshore wind farms require robust and reliable support structures to withstand harsh weather conditions and provide stability for wind turbines. Steel props offer exceptional load-bearing capacity and are capable of withstanding the dynamic forces exerted by wind and waves. Additionally, steel is resistant to corrosion, which is crucial in the offshore environment where exposure to saltwater and moisture is high. Moreover, steel props can be easily adjusted and customized to specific project requirements, making them highly adaptable for different offshore wind farm designs. Overall, steel props are a suitable choice for offshore wind farm construction due to their strength, durability, resistance to corrosion, and versatility.

- Q: Can steel props be used in mining or tunneling projects?

- Mining or tunneling projects can indeed utilize steel props. These props, alternatively referred to as steel supports or steel struts, are frequently employed in such construction endeavors to offer temporary stability and support to excavated tunnels or mine shafts. Their design is specifically crafted to endure substantial loads and pressure, rendering them appropriate for deployment in subterranean settings. Typically, these steel props boast adjustable height features, facilitating effortless installation and adaptation to varying tunnel or mining circumstances. All in all, steel props serve as a dependable and multipurpose means of support, capable of augmenting safety and efficacy within mining and tunneling projects.

- Q: How do you ensure proper load distribution when using multiple steel props?

- Proper load distribution when using multiple steel props can be ensured by following a few essential steps. Firstly, it is important to determine the total load that needs to be supported and distribute it evenly among the props based on their load-bearing capacities. Secondly, the props should be positioned at regular intervals along the load-bearing structure to provide adequate support and prevent any excessive load on a single prop. Additionally, the props should be properly aligned and adjusted to ensure they are all carrying their fair share of the load. Regular monitoring and adjustment of the props during the construction process also help in maintaining proper load distribution.

- Q: Can steel props be used for temporary support in pipeline construction?

- Steel props can indeed be utilized for temporary support in pipeline construction. It is quite common to employ steel props in construction ventures as they offer temporary support to structures and systems. They possess the ability to be adjusted and tailored to meet specific requirements with ease. When it comes to pipeline construction, steel props can effectively bear the weight of the pipeline while ensuring stability during the installation phase. Moreover, they can be deployed to reinforce specific locations where additional support is necessary. Due to their strength, durability, and impressive load-bearing capacity, steel props are perfectly suited for providing temporary support in pipeline construction.

- Q: Can steel props be used for supporting temporary seating arrangements or bleachers?

- Yes, steel props can be used for supporting temporary seating arrangements or bleachers. Steel props are commonly used in construction and temporary structures due to their strength and stability.

- Q: Are steel props suitable for use in modular construction projects?

- Indeed, steel props are a fitting choice for implementation in modular construction projects. Adjustable steel columns or steel shore props, also commonly referred to as steel props, are frequently employed in construction endeavors to offer provisional support to structures during construction or renovation. They are specifically designed to be adjustable in height, allowing for simple installation and adaptability to various construction situations. Within the realm of modular construction, which involves erecting buildings off-site and subsequently relocating them to their final destination for assembly, steel props play a pivotal role in furnishing temporary support to the modular components. These props are instrumental in ensuring the stability of the structure during transportation and installation, thereby averting any potential harm or structural failure. Steel props deliver several advantages in modular construction projects. Primarily, they possess considerable strength and robustness, capable of withstanding substantial loads and supplying the requisite stability to the modular components. This attribute is particularly significant in modular construction, as the components must endure the stresses of transportation and assembly. Furthermore, steel props possess adjustable height capabilities, enabling effortless accommodation for different floor levels or uneven surfaces. This flexibility renders them suitable for a wide array of modular construction projects, as varying heights and configurations may be necessitated. Moreover, steel props exhibit exceptional durability and longevity, enabling them to withstand the challenges posed by construction environments. Typically composed of top-grade steel, which boasts superior strength and corrosion resistance, these props are equipped to endure the rigors of modular construction projects and provide dependable support throughout the process. In conclusion, steel props are unquestionably appropriate for implementation in modular construction projects. Their strength, adjustability, and durability render them an ideal choice for furnishing temporary support to modular components during transportation, assembly, and throughout the construction process.

- Q: What is the weight of a typical steel prop?

- The weight of a typical steel prop can vary depending on its size and specifications. However, on average, a standard steel prop typically weighs around 10 to 15 kilograms (22 to 33 pounds). It is important to note that the weight can vary based on factors such as the length, diameter, and construction materials of the prop.

Send your message to us

Steel Prop & Tripod & Beam Clamp For Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords