Geocells for Driveways - Biaxial Steel Plastic Geogrids for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Jiangsu, China (Mainland)

Brand Name:

Lonrace

Model Number:

geogrid

Material:

Polyester

Color:

White Black Gray Etc

Tensile strength:

25Kn/m--300Kn/m

Length:

50-100m

Certification:

CE /ISO9001

Coating:

PVC

Product Introduction

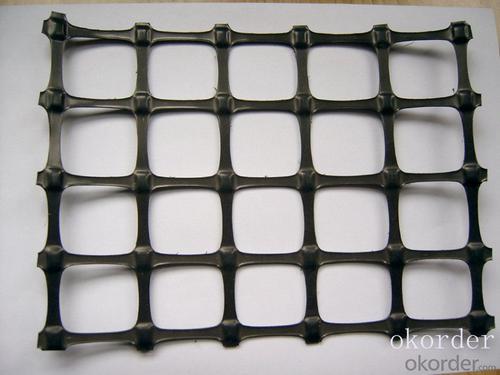

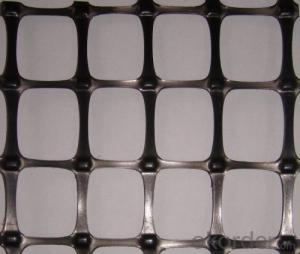

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

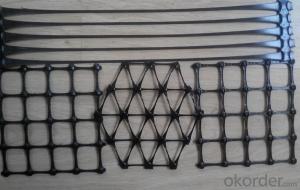

A: Yes, please check the pictures:

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids typically require regular inspection to ensure proper functioning and longevity. This may include checking for damage or deterioration, removing any debris or vegetation, and ensuring proper alignment and tension. Additionally, geogrids should be protected from excessive UV exposure and harsh environmental conditions to maintain their effectiveness.

- Q: How do geogrids help in reducing soil compaction?

- Geogrids help in reducing soil compaction by providing reinforcement and stabilization to the soil. They distribute the applied load more evenly, preventing concentrated pressure points that can lead to compaction. This allows for better load-bearing capacity, improved soil structure, and increased permeability, ultimately reducing the likelihood of soil compaction.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength, stability, and reinforcement to the structure. They help distribute and transfer the loads more efficiently, improving the overall stability and resistance to deformation of the geotextile tubes.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement to the soil structure, which helps distribute the load more evenly and prevent excessive settlement. They act as a stabilizing element by increasing the tensile strength of the soil, preventing its movement and settling.

- Q: What is the effect of creep rupture on geogrid performance?

- The effect of creep rupture on geogrid performance is detrimental as it leads to a significant decrease in the geogrid's strength and stability over time. Creep rupture refers to the gradual elongation or deformation of a material under constant load, which can eventually result in the geogrid failing and losing its ability to provide reinforcement or confinement. This can compromise the overall integrity and effectiveness of the geogrid in various civil engineering applications, such as soil stabilization, slope reinforcement, or retaining wall construction. Therefore, managing and minimizing creep rupture is crucial to maintaining the long-term performance and durability of geogrids.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones?

- Geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones by enhancing the stability and resistance to seismic forces. The geogrids act as a reinforcement material, increasing the tensile strength and preventing soil movement during seismic events. They help distribute the seismic forces more evenly, reducing the potential for slope failure and improving overall slope stability.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of the geogrid material used can significantly impact the overall cost. Higher-quality geogrids may initially be more expensive but offer better long-term performance, potentially reducing maintenance and repair costs over time. Additionally, the design and engineering of the structure play a crucial role. Properly designed geogrid-reinforced structures can optimize material usage and minimize construction costs. The expertise and experience of the engineers and contractors involved also contribute to the cost-effectiveness, as their knowledge can help avoid unnecessary expenses and ensure efficient construction. The specific site conditions, such as soil characteristics and slope stability, are also important factors. Geogrids are typically used to enhance soil stability, so the suitability of the soil for reinforcement and the extent of reinforcement required can impact costs. Difficult terrain, challenging access, or the need for additional site preparation can also increase costs. Lastly, the lifespan and durability of geogrid-reinforced structures should be considered. While geogrids are designed to be long-lasting, factors like environmental conditions, loading requirements, and proper installation can affect their performance. Investing in high-quality materials and proper installation methods may initially increase costs but can result in longer service life and reduced maintenance expenses in the long run.

- Q: Can geogrids be used in stormwater management applications?

- Yes, geogrids can be used in stormwater management applications. Geogrids are often used to reinforce and stabilize soil in various construction projects, including stormwater management systems. They help to improve the strength and stability of the soil, allowing it to better withstand the forces and pressures exerted by stormwater. Additionally, geogrids can also enhance the performance of stormwater management structures by preventing soil erosion and promoting water infiltration. Overall, geogrids are a valuable tool in stormwater management applications.

- Q: Geogrid prices and geogrid manufacturers?

- 2, the use of Geogrid on the railway to avoid the soft ground on the basis of the railway premature settlement and destruction of real estate3, the geogrid used in the dam, dam, river, canal, Wai sea embankment, reservoir reinforcement and other water conservancy projects

- Q: Do geogrids provide reinforcement to geosynthetic liners?

- Yes, geogrids can provide reinforcement to geosynthetic liners. Geogrids are typically used in geosynthetic liner systems to enhance the overall strength, stability, and performance of the liners. They help distribute loads, reduce deformation, and improve the long-term performance of geosynthetic liners.

Send your message to us

Geocells for Driveways - Biaxial Steel Plastic Geogrids for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords