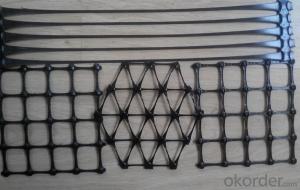

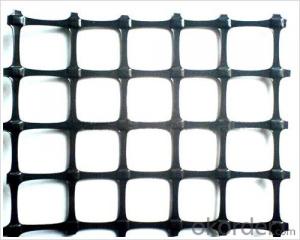

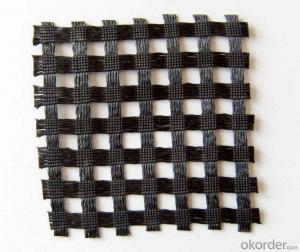

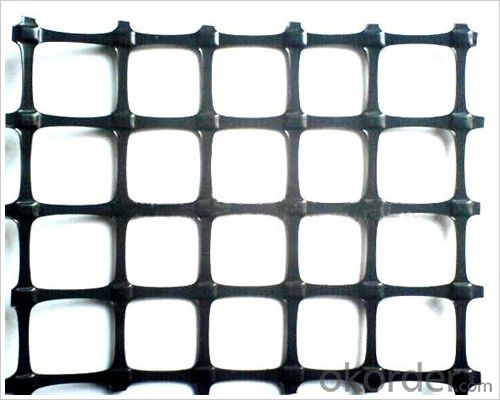

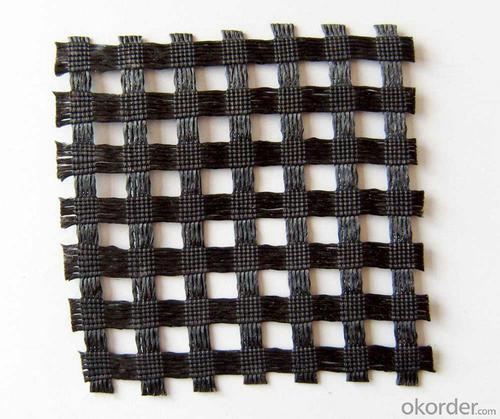

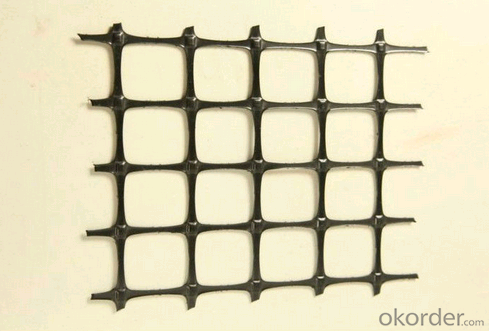

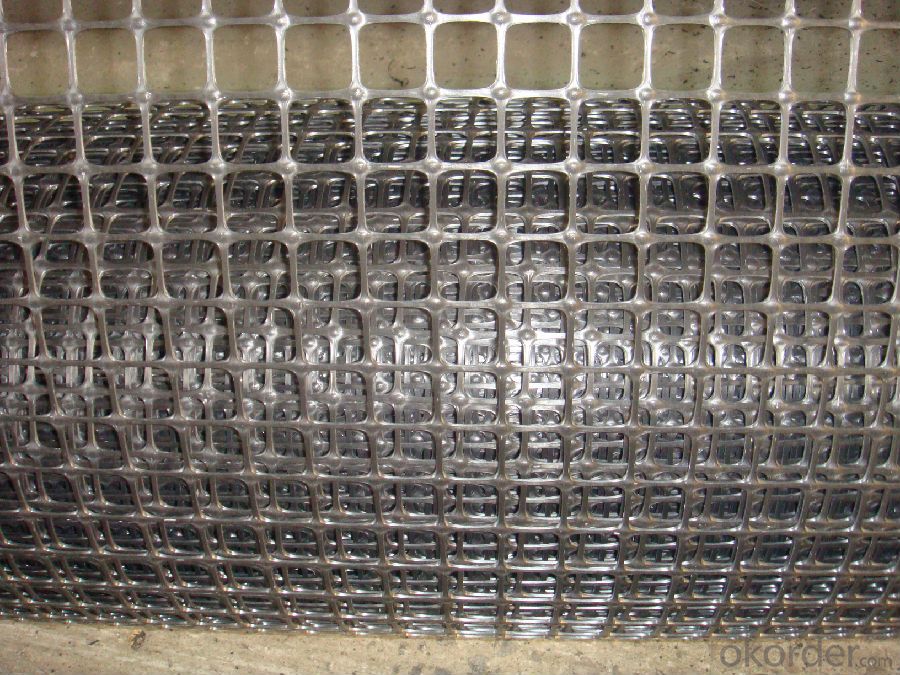

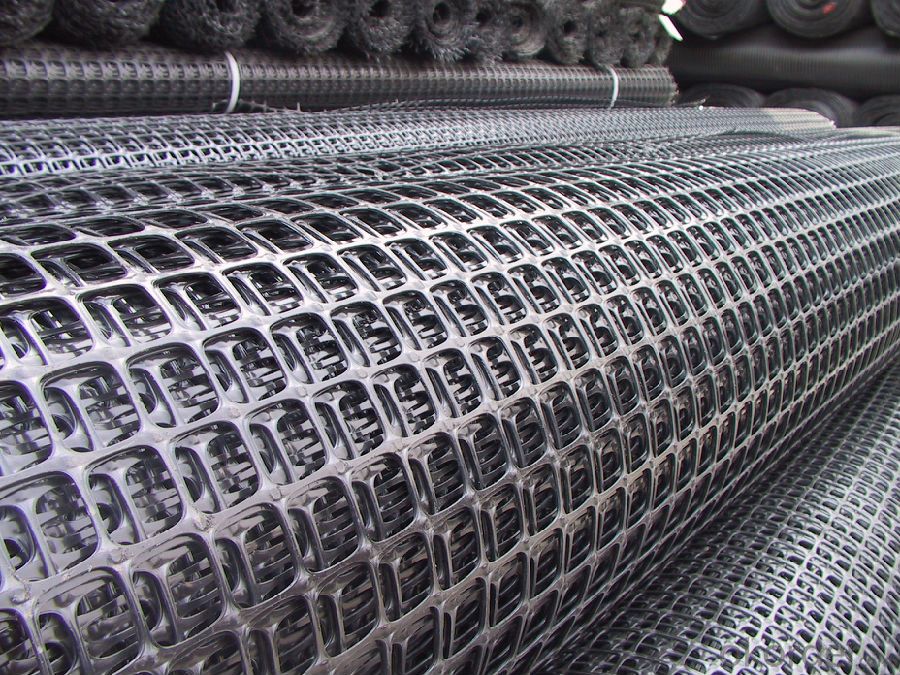

Geogrids for Roads - Uniaxial/Biaxial/Multiway Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

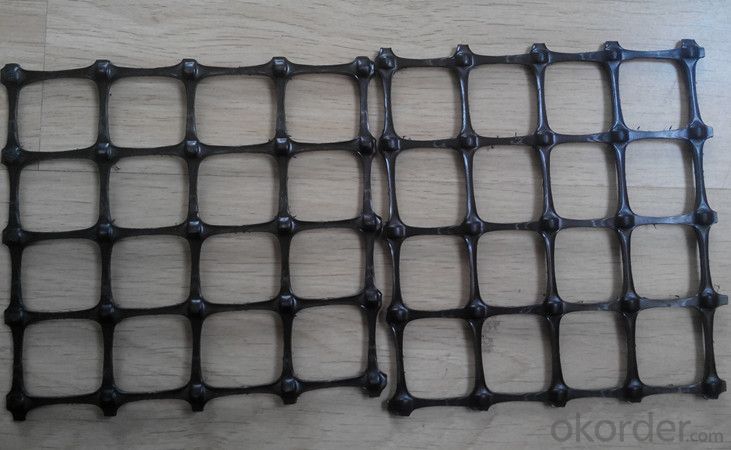

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: Are geogrids resistant to seismic forces?

- Yes, geogrids are resistant to seismic forces. They are designed to provide reinforcement and stability to soil structures, including retaining walls and slopes, during seismic events. Geogrids help distribute and dissipate the forces generated by earthquakes, reducing the risk of structural failure and enhancing overall stability.

- Q: What are the different installation methods for geogrids?

- There are several installation methods for geogrids, including direct placement, trenching and backfilling, and mechanical installation. Direct placement involves laying the geogrid directly on the subgrade or soil surface and then covering it with a layer of aggregate. Trenching and backfilling method involves excavating a trench, placing the geogrid in the trench, and then backfilling it with soil or aggregate. Mechanical installation methods use specialized equipment, such as a geogrid installation machine, to unroll and place the geogrid in the desired location. The chosen installation method depends on factors such as the application, site conditions, and specific project requirements.

- Q: What are the procedures for using two-way geogrid

- 8 bidirectional geogrid construction methods: subgrade excavation, setting sand cushion (height of not more than 10cm), rolled into a platform, laying grille, longitudinal and main stress direction, the longitudinal joints 15-20cm, lateral 10cm, lashing plastic belt joint, and in the laying of the grille, every 1.5-2m with U the nail is fixed on the ground, laying geogrid should be timely backfill material, laying geogrid layers as technical requirements.

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength and stability. They act as a reinforcement layer within the tube, preventing deformation and maintaining the desired shape. Geogrids also help distribute the load evenly, increasing the overall stability and durability of the geotextile tube system.

- Q: Are geogrids resistant to biological degradation?

- Yes, geogrids are generally resistant to biological degradation.

- Q: How do geogrids enhance soil reinforcement?

- Geogrids enhance soil reinforcement by providing additional tensile strength and stability to the soil. They are placed within the soil layers and act as a reinforcement material, distributing the forces and reducing the potential for soil movement. This helps to increase the overall strength and performance of the soil, making it more resistant to erosion, deformation, and other types of failures.

- Q: Are geogrids suitable for reinforcement of soft soils?

- Yes, geogrids are suitable for reinforcement of soft soils. They provide a stabilizing effect by distributing the load and preventing excessive settlement or deformation. Geogrids also improve the strength and stability of the soil, making them an effective solution for reinforcing soft soils.

- Q: How do geogrids enhance the performance of geotextiles?

- Geogrids enhance the performance of geotextiles by providing additional reinforcement and stability to the soil. They work by interlocking with the soil particles and distributing the applied loads more evenly, which helps to prevent soil erosion, improve load-bearing capacity, and increase the overall strength and durability of the geotextile system.

- Q: How do geogrids enhance the stability of steep fill slopes?

- Geogrids enhance the stability of steep fill slopes by providing reinforcement and reducing soil erosion. They act as a barrier, distributing the load more evenly across the slope and increasing the overall strength of the soil. This prevents the slope from sliding or collapsing under the weight of the fill material. Additionally, geogrids improve drainage and prevent water accumulation, which is crucial in maintaining slope stability.

Send your message to us

Geogrids for Roads - Uniaxial/Biaxial/Multiway Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords