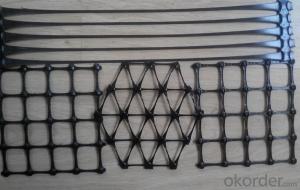

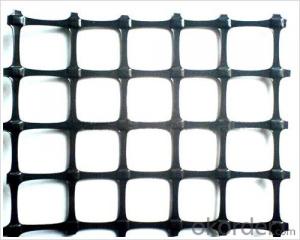

Biaxial Plastic Steel Geogrids for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Plastic Steel Geogrid Description

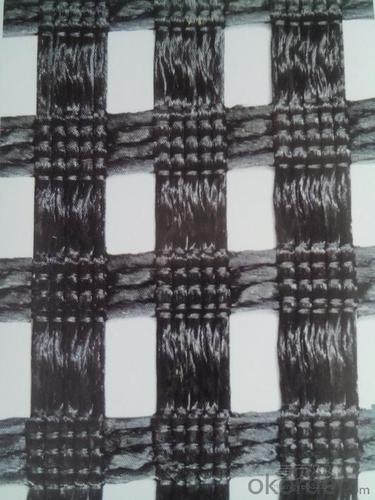

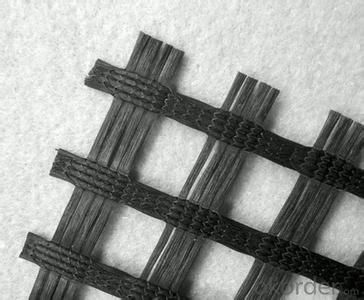

Plastic Steel Geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips.

2. Plastic Steel Geogrid Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Plastic Steel Geogrid Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

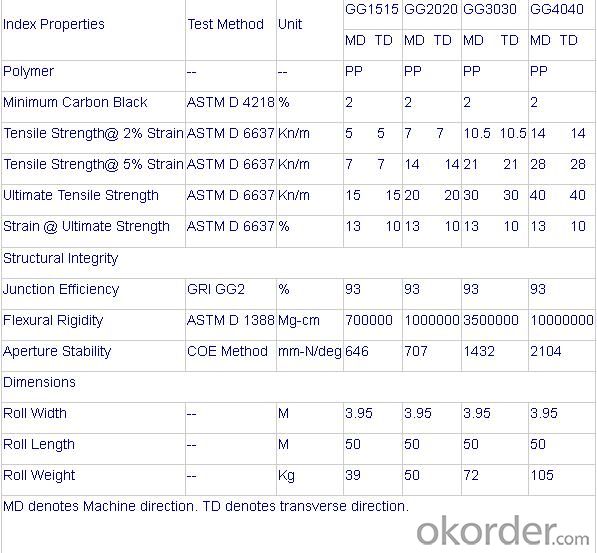

4. Plastic Steel Geogrid Specification

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Geogrid manufacturers and the price is how much?

- Geogrid is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Uniaxial Plastic Geogrid

- Q: Can geogrids be used in shoreline protection?

- Yes, geogrids can be used in shoreline protection. Geogrids are commonly used to stabilize and reinforce soil, including in coastal areas. They can provide erosion control, improve soil stability, and enhance the overall resilience of shorelines against waves and tidal forces.

- Q: Can geogrids be used in slope stabilization?

- Yes, geogrids can be used in slope stabilization. Geogrids are commonly used in slope stabilization projects as they provide reinforcement and enhance the stability of soil and slopes. They help distribute loads, increase soil shear strength, and prevent soil erosion. Geogrids are effective in stabilizing slopes and preventing landslides, making them a suitable solution for slope stabilization.

- Q: Can geogrids be used in subgrade improvement?

- Yes, geogrids can be used in subgrade improvement. Geogrids are often used in civil engineering projects to reinforce and stabilize weak soils in the subgrade. They can help to distribute loads more evenly, increase bearing capacity, and reduce settlement. Additionally, geogrids can improve the overall performance and longevity of the subgrade, making them a valuable tool in subgrade improvement projects.

- Q: What are the factors affecting the design of geogrid-reinforced structures?

- Some factors affecting the design of geogrid-reinforced structures include the type and properties of the soil, the desired strength and stability of the structure, the anticipated loads and stresses, the environmental conditions, the geometry and layout of the structure, and the availability and cost of materials.

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.

- Q: Are geogrids resistant to UV degradation?

- Yes, geogrids are generally resistant to UV degradation. They are designed to withstand prolonged exposure to sunlight without significant degradation or loss of strength.

- Q: Can geogrids be used in bridge abutment reinforcement?

- Yes, geogrids can be used in bridge abutment reinforcement. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil structures, such as bridge abutments. They provide additional tensile strength and prevent soil erosion, helping to enhance the overall performance and longevity of the bridge abutment.

- Q: Can geogrids be used in shoreline protection projects?

- Yes, geogrids can be used in shoreline protection projects. Geogrids are commonly used to reinforce and stabilize soil in various construction projects, including shoreline protection. They help to prevent soil erosion and provide structural support, making them suitable for use in shoreline protection projects to enhance the stability and resilience of the shoreline.

- Q: Are geogrids suitable for use in mechanically stabilized bridge abutments?

- Yes, geogrids are suitable for use in mechanically stabilized bridge abutments. Geogrids provide reinforcement and stability to the soil behind the abutments, preventing lateral movement and potential failure. They are highly effective in enhancing the load-bearing capacity and durability of bridge abutments, making them a reliable and commonly used solution in civil engineering projects.

Send your message to us

Biaxial Plastic Steel Geogrids for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords