Steel Billet from China Alibaba Q215 Q235 Q275

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17684 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and

molding.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support

foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

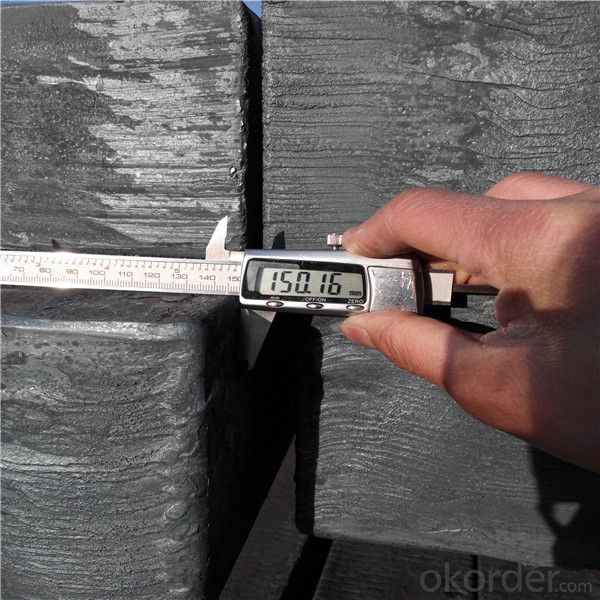

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different types of surface treatment methods used for steel billets?

- Steel billets can undergo various surface treatment methods to serve specific purposes. Here are some commonly employed techniques: 1. Pickling: By immersing steel billets in an acidic solution, typically hydrochloric or sulfuric acid, any scale or oxide layers on the surface can be eliminated. Pickling enhances the surface finish and readies the steel for further processing. 2. Shot Blasting: This method involves propelling high-velocity small metal or ceramic particles onto the steel billet surface. The process effectively removes rust, scale, and contaminants, resulting in a clean and smooth finish. 3. Grinding: To eradicate imperfections from the steel billet surface, mechanical abrasive wheels are utilized. Grinding can achieve a specific surface roughness, making it ideal for precision and accuracy requirements. 4. Acid Etching: By applying an acid solution to the steel billet surface, a controlled roughness or texture can be created. This enhances subsequent coating or paint adhesion. 5. Galvanizing: A layer of zinc is applied to the steel billets in this popular method. Zinc acts as a sacrificial barrier, providing excellent corrosion resistance and protecting the underlying steel from oxidation. 6. Powder Coating: Electrostatically applying a dry powder to the steel billet surface characterizes this technique. Upon heating, the powder melts and forms a protective layer known for its durability, corrosion resistance, and ability to offer diverse decorative finishes. 7. Passivation: This chemical process aims to enhance the corrosion resistance of stainless steel billets. It involves eliminating iron contaminants and forming a passive oxide layer that safeguards the steel from oxidation. These examples represent only a fraction of the surface treatment methods available for steel billets. The selection of a method depends on factors like desired surface finish, intended steel application, and required level of corrosion resistance.

- Q: What are the different types of shearing machines used for steel billets?

- Steel billets can be cut using various types of shearing machines. These machines are designed for precise and efficient cutting operations in the steel industry. Here are some examples of the different shearing machines used for steel billets: 1. Guillotine Shears: Guillotine shears are widely used for cutting steel billets. They have a fixed bed and a vertically moving blade that cuts through the material. Guillotine shears offer high cutting accuracy and can easily handle thick billets. 2. Flying Shears: Also known as rotary shears, flying shears are another popular option. They have a circular blade that rotates and cuts the billet as it moves along the conveyor. Flying shears are known for their high cutting speed and ability to handle large volumes. 3. Cold Shears: Cold shears are designed to cut steel billets at lower temperatures to prevent heat damage. They use hydraulic or mechanical systems to apply force and cut through the billet. Cold shears are commonly used in industries where cooling the billets is necessary before further processing. 4. Rotary Shears: Rotary shears are used to cut steel billets into smaller sections. They have multiple blades mounted on a rotating drum, which cuts the billet into desired lengths. Rotary shears offer high cutting efficiency and are often used when small-sized billets are required. 5. Hydraulic Shears: Hydraulic shears are versatile machines that can cut various materials, including steel billets. They use hydraulic power to provide the cutting force. Hydraulic shears have a high cutting speed and can efficiently handle large-sized billets. Each type of shearing machine mentioned above has its own advantages and is suitable for specific applications in the steel industry. The choice of shearing machine depends on factors such as billet size and thickness, required cutting accuracy, production volume, and other specific requirements of the steel processing operation.

- Q: How are steel billets used in the production of railway components?

- Railway components rely heavily on steel billets during the production process. These billets, which are essentially semi-finished steel products, serve as the foundation for manufacturing various railway components such as rails, wheels, axles, and structural parts. To create railway components, steel billets are first heated to a specific temperature, enhancing their malleability. This crucial heating process enables easy shaping and forming of the steel into the desired component. Once the billets reach the required temperature, they proceed to the next stage of production. Here, they undergo processes like rolling, forging, and machining to transform them into the final shape and size needed for the specific railway component. For example, in the production of railway rails, heated steel billets pass through a series of rolling mills, gradually shaping and elongating them into the desired rail profile. Similarly, for wheels and axles, billets are forged and machined to achieve the necessary dimensions and surface finish. The utilization of steel billets ensures that the resulting railway components possess strength, durability, and the ability to withstand the heavy loads and stresses associated with railway operations. The quality and characteristics of the steel billets greatly influence the performance and lifespan of the railway components. In summary, steel billets play a critical role in producing railway components by providing the raw material that is shaped, formed, and processed into the essential final products for the safe and efficient operation of the railway system.

- Q: What are the different types of surface finish methods used for steel billets?

- There are several types of surface finish methods used for steel billets, including hot rolling, cold rolling, sandblasting, polishing, and galvanizing.

- Q: What are the common surface defects in steel billets during cooling?

- Common surface defects in steel billets during cooling include cracks, surface scaling or oxidation, and surface decarburization.

- Q: How are steel billets tested for mechanical properties?

- Steel billets are tested for mechanical properties through various methods such as tensile testing, hardness testing, and impact testing. Tensile testing involves subjecting the billets to tension until they fracture, measuring their strength and ductility. Hardness testing determines the billets' resistance to indentation or penetration, indicating their overall strength. Impact testing assesses the billets' ability to absorb energy by subjecting them to a sudden load, measuring their toughness. These tests ensure that the steel billets meet the required mechanical properties for their intended applications.

- Q: How are steel billets used in the manufacturing of structural components?

- The manufacturing of structural components heavily relies on steel billets, which are an essential raw material. These billets, usually square or round in shape, are produced through continuous casting, a process that solidifies molten steel into a semi-finished product. After the formation of steel billets, they undergo further processing using different techniques like hot rolling, forging, or extrusion. Hot rolling includes heating the billets and passing them through a sequence of rollers to shape them into desired profiles, such as beams, channels, or angles. This method is crucial for achieving the necessary dimensions, strength, and surface finish. Forging is another technique employed with steel billets, involving heating the billets and shaping them using compressive forces. It is primarily used for manufacturing components that require enhanced strength and durability, like crankshafts, connecting rods, or turbine blades. Extrusion, on the other hand, is a specialized process that utilizes heated billets to create complex shapes by forcing them through a die. This technique is commonly utilized in the production of tubular components, such as pipes, tubes, or hollow sections. These components are extensively used in the construction of structures like bridges, buildings, or infrastructure. Steel billets play a critical role in the manufacturing of structural components by providing the necessary raw material that can be shaped using various fabrication techniques. Their adaptability and versatility make them an indispensable component in the construction industry, ensuring that buildings and structures possess the required strength and durability to withstand different loads and environmental conditions.

- Q: What are the different surface treatments applied to steel billets?

- There are several different surface treatments that can be applied to steel billets, depending on the desired end result and application. Some of the common surface treatments for steel billets include: 1. Shot Blasting: This process involves propelling small metal or mineral particles at high speed onto the surface of the steel billets. Shot blasting helps to remove any surface impurities, such as rust or scale, resulting in a clean and uniform surface. 2. Pickling: Pickling is a chemical treatment that involves immersing the steel billets in an acid solution, typically hydrochloric or sulfuric acid. This process helps to remove any oxide layers or scale from the surface of the billets, resulting in a clean and smooth surface. 3. Phosphating: Phosphating is a chemical conversion coating process that involves immersing the steel billets in a solution containing phosphate salts. This treatment helps to create a thin, adherent, and corrosion-resistant phosphate film on the surface of the billets. 4. Galvanizing: Galvanizing is a popular surface treatment for steel billets that involves coating them with a layer of zinc. This process helps to provide excellent corrosion protection and enhances the overall durability of the steel billets. 5. Painting: Painting is another common surface treatment for steel billets, where a layer of paint is applied to the surface. This can provide both aesthetic appeal and additional protection against corrosion. 6. Electroplating: Electroplating is a process where a thin layer of metal, such as chromium or nickel, is deposited onto the surface of the steel billets using an electrical current. This treatment can enhance the appearance, corrosion resistance, and wear resistance of the steel billets. It is important to note that the choice of surface treatment for steel billets depends on various factors, including the intended use, environmental conditions, and cost considerations. Each treatment offers specific advantages and it is crucial to select the most suitable option to ensure optimal performance and longevity of the steel billets.

- Q: What are the main factors affecting the mechanical properties of steel billets?

- There are several main factors that can affect the mechanical properties of steel billets. 1. Chemical Composition: The chemical composition of steel, specifically the amounts of carbon, alloying elements, and impurities, plays a significant role in determining its mechanical properties. Higher carbon content usually leads to increased strength but reduced ductility. Alloying elements such as manganese, nickel, and chromium can enhance specific properties like hardness, toughness, or corrosion resistance. 2. Heat Treatment: The heat treatment process, which involves heating and cooling the steel billets under controlled conditions, can greatly influence their mechanical properties. Different heat treatment methods, such as annealing, quenching, and tempering, can alter the microstructure and consequently the hardness, strength, and toughness of the steel. 3. Microstructure: The microstructure of steel, which is determined by the cooling rate during solidification or heat treatment, is another crucial factor. The presence of different phases, grain size, and distribution of alloying elements within the microstructure can significantly affect the steel's mechanical properties. 4. Manufacturing Process: The manufacturing process used to produce steel billets can also impact their mechanical properties. Factors such as casting method, rolling or forging techniques, and the presence of any defects or impurities introduced during production can influence the final properties of the billets. 5. Temperature: Temperature has a considerable influence on the mechanical properties of steel. It can affect the strength, ductility, and toughness of the material. For instance, as temperature decreases, steel tends to become more brittle, whereas at elevated temperatures, it may exhibit reduced strength and increased ductility. 6. Strain Rate: The rate at which a load is applied to the steel billets, known as strain rate, can affect their mechanical properties. High strain rates, such as those experienced during rapid impact or dynamic loading, can result in different behavior and failure mechanisms compared to slower or static loading conditions. It is important to note that these factors are interrelated, and changes in one factor can influence others, leading to a complex interaction and a wide range of possible mechanical properties for steel billets.

- Q: What is the lifespan of steel billets?

- The durability of steel billets can be influenced by several factors, including the steel quality, storage conditions, and specific usage. When properly stored and maintained, steel billets can have a considerably long lifespan. Under favorable circumstances, these billets can endure for numerous years without notable deterioration. Nevertheless, if exposed to harsh environmental elements like moisture, extreme temperatures, or corrosive substances, their lifespan may be significantly shortened. It is crucial to handle and store steel billets with care to minimize any potential harm and guarantee their prolonged existence.

Send your message to us

Steel Billet from China Alibaba Q215 Q235 Q275

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17684 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords