Geotextil Para Jardines Verticales - Staple Fibers Punched Non Woven Geotextile Direct Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Staple fibers needle punched non woven geotextile is made of PP or PET staple fibers on carding cross- laying equipment and needle punched equipment.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Properties of Staple fibers needle punched non woven geotextile

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

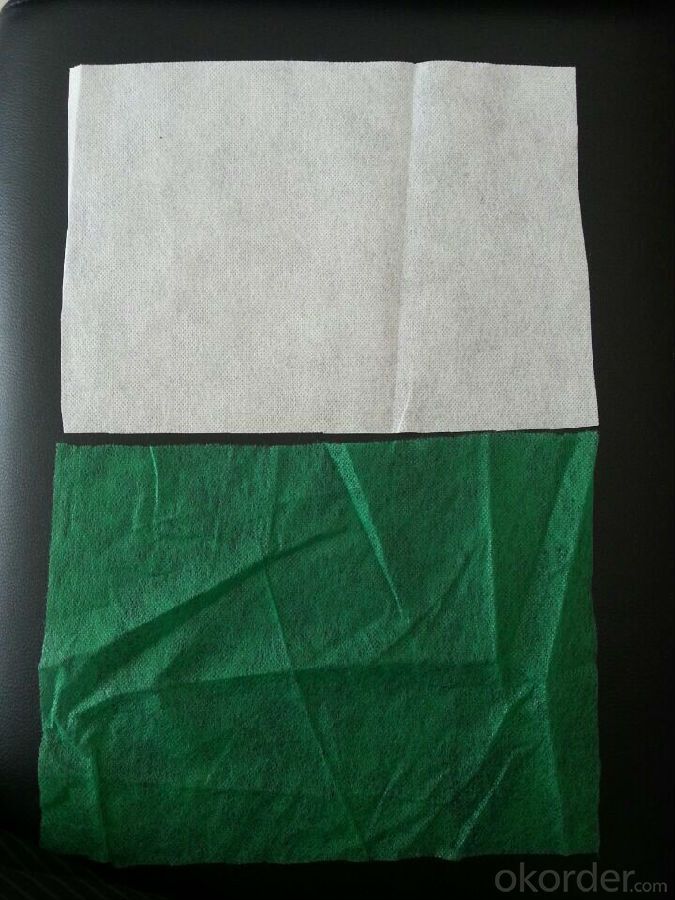

Images of non woven geotextile

- Q: Principle of drainage pipe geotextile

- Principle of drainage pipe geotextile

- Q: Pvc waterproof board and geotextile must be used with what

- To stick together, I specialize in producing pvc waterproof board and geotextile and other geotextile materials

- Q: Can geotextiles be used in railway projects?

- Yes, geotextiles can be used in railway projects. Geotextiles are commonly used in railway construction to improve the stability, strength, and durability of the railway track. They are used for separation, filtration, drainage, and reinforcement purposes. Geotextiles help in preventing the mixing of different soil layers, enhancing drainage, and providing additional strength to the track structure, ultimately ensuring the longevity and performance of the railway infrastructure.

- Q: Geotextile is what is the role to play with what?

- Geotextile can seep the water penetration, so its use a lot of floods covered in the embankment on the isolation of water supply to the earth dam erosion, placed around the pool to prevent the water inside the pool into the earth, laying in the pollutant storage site to prevent contaminants contaminated land And groundwater, and so on

- Q: How much is the geotextile machine?

- Geotextile is very cheap a few hundred dollars, geomembrane is more expensive, 4000-8000 yuan, I specializing in the production of geomembrane geotextile

- Q: Roof geotextile isolation layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: How do geotextiles help with sediment filtration in stormwater ponds?

- Geotextiles help with sediment filtration in stormwater ponds by acting as a physical barrier that prevents sediment from entering the water body. These permeable fabrics allow water to pass through while trapping sediment particles, thereby reducing the amount of pollutants and sediments that can harm aquatic ecosystems.

- Q: Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles provide additional reinforcement and stability to the soil, enhancing the performance of geogrids in slope stabilization. They help in preventing soil erosion, reducing water infiltration, and improving overall slope stability.

- Q: With sand and gravel, geotextile do blind ditch how to construction

- Geotextile wrapped sand and gravel, play a role in filtering drainage, the equivalent of the use of blind ditch, Ji child irrigation twisted thieves ghost Creek Handan Huaxu geotextile material manufacturers

- Q: What are the specifications for geotextiles in wastewater treatment projects?

- The specifications for geotextiles in wastewater treatment projects typically include requirements for strength, filtration efficiency, and durability. Additionally, they may specify the type and weight of geotextile fabric to be used, as well as any necessary certifications or testing standards that need to be met. Geotextiles used in wastewater treatment projects are typically designed to provide effective filtration and separation of solids, while also being resistant to chemical degradation and capable of withstanding the harsh conditions present in wastewater treatment facilities.

Send your message to us

Geotextil Para Jardines Verticales - Staple Fibers Punched Non Woven Geotextile Direct Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords