Bâche Géotextile - Staple Fibers Needle Punched Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

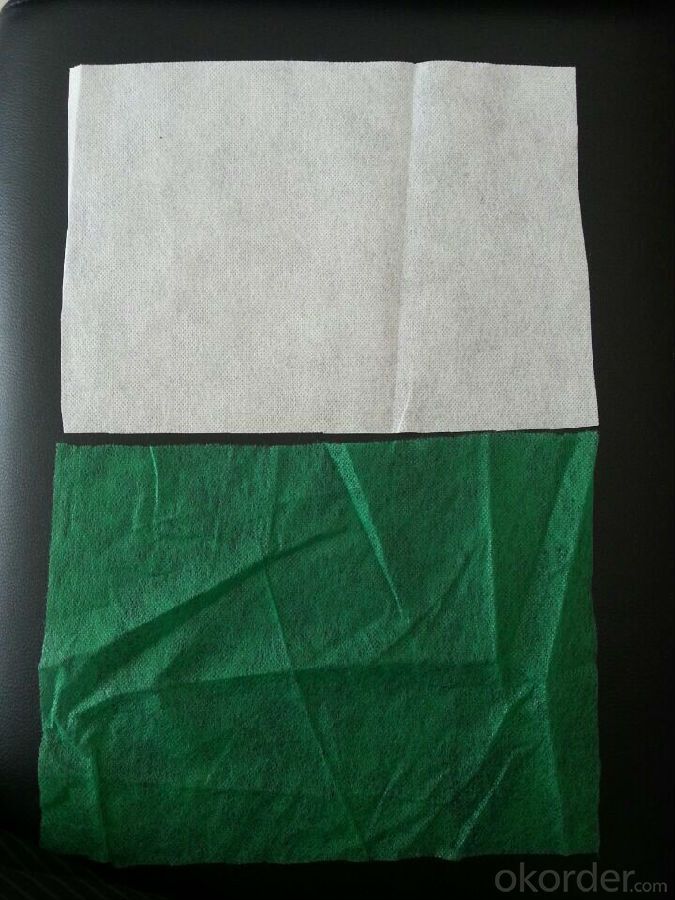

Staple fibers needle punched non woven geotextile

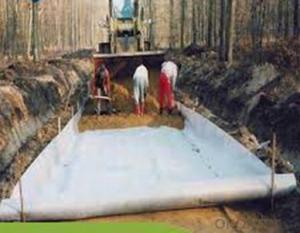

Filament geotextile mainly applied in water conservancy, road, railway, dam and tunnel for separation, filtration, reinforcement and drainage of projects

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Specification:100g~800g

Properties of Staple fibers needle punched non woven geotextile

Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

Images of non woven geotextile

- Q: What are the long-term performance expectations for geotextile installations?

- The long-term performance expectations for geotextile installations are generally high. Geotextiles are designed to provide durable and effective solutions for various applications such as soil stabilization, erosion control, and drainage systems. With proper installation and maintenance, geotextiles can typically last for decades, providing long-lasting functionality and performance. However, specific performance expectations may vary depending on factors such as the type of geotextile, site conditions, and the intended application.

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing erosion control, stabilization, and reinforcement. These synthetic fabrics are installed between the soil layers of the slope, acting as a barrier to prevent soil movement and erosion caused by water flow or wind. Geotextiles also enhance the overall stability of the slope by improving soil drainage, reducing pore water pressure, and increasing soil strength.

- Q: Are geotextiles suitable for use in waste containment systems?

- Yes, geotextiles are suitable for use in waste containment systems. They provide effective filtration, separation, and reinforcement properties, helping to prevent the migration of fine particles and contaminants into the surrounding environment. Geotextiles also enhance the stability and durability of waste containment systems, making them an ideal choice for various waste management applications.

- Q: After the laying of drainage board and then need to lay a layer of geotextile it?

- Yes, from the role of filtration, over the water, but to prevent clogging, I professional production

- Q: How do geotextiles contribute to the stability of road embankments?

- Geotextiles contribute to the stability of road embankments by providing reinforcement and separation between soil layers. They act as a barrier, preventing the mixing of different soil types and enhancing the load-bearing capacity of the embankment. This helps to distribute the applied loads more evenly, reducing settlement and potential failure. Additionally, geotextiles improve drainage and prevent the loss of soil particles, reducing the risk of erosion and maintaining the embankment's integrity over time.

- Q: Do you need to cover the geotextile?

- Generally less than geotextile, I am specializing in the production of geotechnical materials

- Q: Can geotextiles be used in the construction of golf course bunkers?

- Yes, geotextiles can be used in the construction of golf course bunkers. Geotextiles are commonly used in construction projects to stabilize and reinforce soil. In the case of golf course bunkers, geotextiles can be used to prevent erosion, improve drainage, and provide a stable base for the sand.

- Q: Are geotextiles biodegradable?

- No, geotextiles are not biodegradable.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in various oil and gas industry applications. They are commonly used in areas such as erosion control, filtration, dewatering, and soil stabilization. Geotextiles can help prevent soil erosion, protect pipelines from damage, and provide reinforcement in construction projects. They are versatile and cost-effective materials that offer numerous benefits in the oil and gas industry.

- Q: Can geotextiles be used in geogrid reinforced slopes?

- Yes, geotextiles can be used in geogrid reinforced slopes. Geotextiles are often used in conjunction with geogrids to enhance their performance and provide additional benefits such as filtration, separation, and erosion control. The geotextile acts as a barrier to prevent fine particles from migrating through the geogrid, while still allowing water to pass through. This combination of geotextiles and geogrids helps to improve the stability and longevity of reinforced slopes.

Send your message to us

Bâche Géotextile - Staple Fibers Needle Punched Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords