Biodegradable Geotextile Fabric - Staple Fibers Punched Non Woven Geotextile Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Staple fibers needle punched non woven geotextile is made of PP or PET staple fibers on carding cross- laying equipment and needle punched equipment.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Properties of Staple fibers needle punched non woven geotextile

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

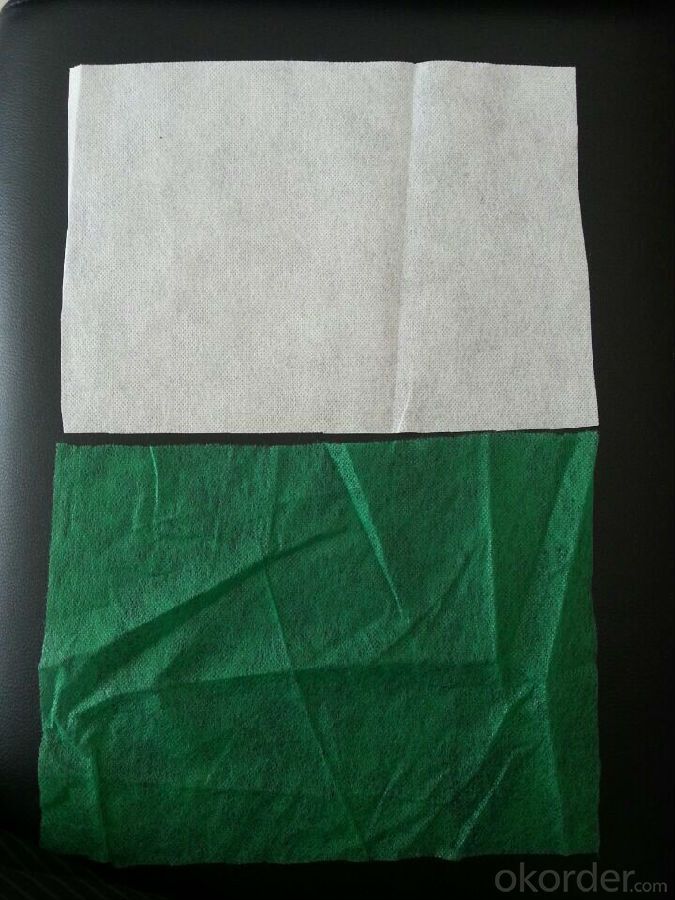

Images of non woven geotextile

- Q: Can geotextiles be used in contaminated soil?

- Yes, geotextiles can be used in contaminated soil. Geotextiles are commonly employed as a barrier or separator in construction projects, including those involving contaminated soil. They can help prevent the migration of contaminants, aid in soil stabilization, and facilitate the filtration and drainage of water. However, the choice of geotextile material and design should be carefully considered to ensure its effectiveness in specific contaminated soil conditions.

- Q: Can geotextiles be used in geocomposite drains?

- Yes, geotextiles can be used in geocomposite drains. Geocomposite drains typically consist of a geotextile fabric wrapped around a core material, such as a perforated pipe. The geotextile helps to filter and separate fine particles from the core material, preventing clogging and enhancing drainage efficiency.

- Q: Principle and Advantages of Permeable Geotextile

- The advantages of permeable geotextile: 1: isolation, the use of polyester staple acupuncture geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of building materials (such as soil and sand, soil and concrete Etc.) to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. 2: filter, when the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small Stone, etc., in order to maintain the stability of soil and water engineering. 3: drainage, polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. 4: reinforced, the use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve the quality of soil. 5: protection, water erosion of the soil, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent soil damage by external forces, the protection of the soil. 6: high tensile strength, good permeability, breathable properties, high temperature, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten.

- Q: Geotextile cloth how many square feet

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: What are the disadvantages of using geotextiles?

- There are several disadvantages of using geotextiles. Firstly, geotextiles can be quite expensive compared to other types of erosion control or soil stabilization methods. Additionally, they may require professional installation, which can add to the overall cost. Secondly, geotextiles are not a permanent solution and may degrade over time due to weather conditions and UV exposure. This can lead to the need for frequent replacements, resulting in additional expenses. Lastly, geotextiles may not be suitable for all soil types or project requirements, as they have limitations in terms of load-bearing capacity and effectiveness in certain applications.

- Q: What are the advantages of using geotextiles in agriculture?

- Geotextiles offer several advantages in agriculture. Firstly, they help in soil reinforcement and stabilization, preventing erosion and soil loss. Secondly, they can act as a barrier, controlling the movement of water, nutrients, and chemicals, thereby enhancing soil fertility and reducing the risk of groundwater contamination. Additionally, geotextiles promote better root development and plant growth by providing a stable and well-drained environment. Lastly, they contribute to weed control, reducing the need for herbicides and manual labor. Overall, geotextiles serve as an effective and sustainable solution in agriculture, improving soil health, crop yield, and environmental sustainability.

- Q: Can geotextiles be used in geogrid reinforced soil walls?

- Yes, geotextiles can be used in geogrid reinforced soil walls. Geotextiles are often used as a separation layer between the soil and the geogrids to prevent soil loss and provide additional reinforcement to the wall structure.

- Q: 250 grams of geotextile how much money a square

- Geotextile latest offer, up to 2.0 yuan geotextile material manufacturers to answer

- Q: Waterproof geotextile market demand prospects?

- Supply geotextile, geomembrane, composite geomembrane and other geotechnical materials. Market prospects are excellent. Geotechnical material manufacturers to answer your questions

- Q: What are the factors to consider when selecting geotextiles?

- When selecting geotextiles, some important factors to consider include the type of project or application, the required strength and durability, the desired permeability and filtration properties, the site conditions such as soil type and slope, the installation and maintenance requirements, as well as cost-effectiveness.

Send your message to us

Biodegradable Geotextile Fabric - Staple Fibers Punched Non Woven Geotextile Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords