Non-Woven Geotextile Drainage Fabric - Needle Punched Staple Fibers Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Staple fibers needle punched non woven geotextile

Introduction:

Staple fibers needle punched non woven geotextile is made of PP or PET staple fibers on carding cross- laying equipment and needle punched equipment.

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Specification:100g~800g

Width:2m~6m

Properties of Staple fibers needle punched non woven geotextile

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

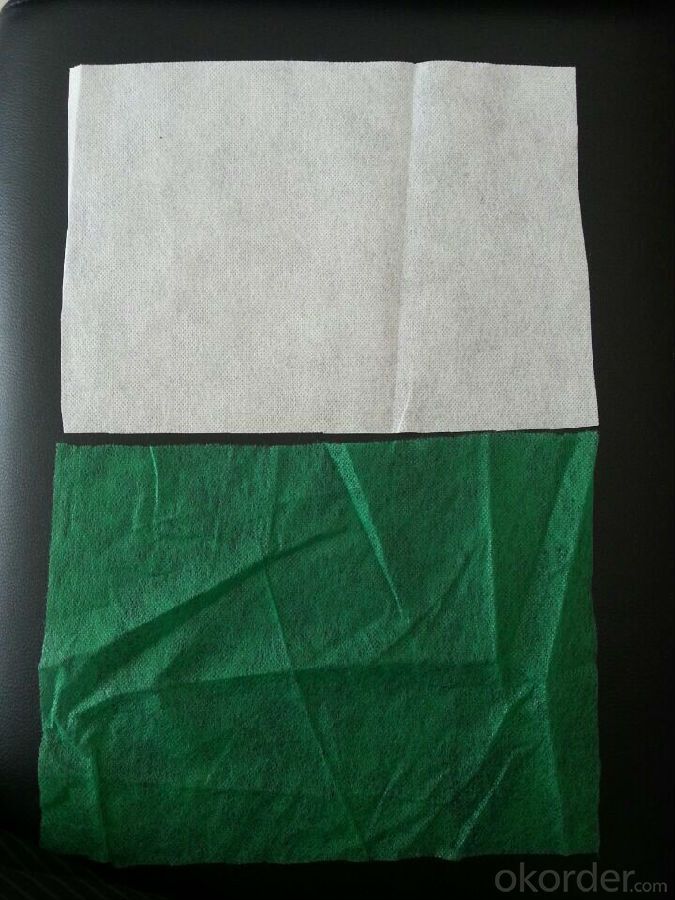

Images of non woven geotextile

- Q: Can geotextiles be used in agriculture?

- Yes, geotextiles can be used in agriculture for various purposes such as erosion control, weed suppression, soil stabilization, and drainage improvement.

- Q: How is this set of water quotas? More

- I also produce geotextiles

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles can provide separation, filtration, and erosion control functions, which are essential for maintaining the stability and performance of geogrid reinforced slopes.

- Q: How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by providing reinforcement and preventing erosion. When placed on the slope, geotextiles act as a barrier, holding the soil in place and preventing it from sliding or eroding downhill. The geotextiles also allow water to pass through while retaining the soil, reducing the impact of heavy rainfall or water flow on the slope. This helps to maintain the integrity of the slope, preventing landslides and ensuring long-term stability.

- Q: Geotextile (250g / square meter) offer

- 250 grams of short fiber geotextile Price: 2.30 yuan / square meter 250 grams of filament geotextile Price: 3.70 yuan / square meter 250 grams of impervious geotextile Price: 2.80 yuan / square meter.

- Q: Can geotextiles be used in coastal revetment works?

- Yes, geotextiles can be used in coastal revetment works. Geotextiles are often used in coastal engineering projects as they provide erosion control, stabilization, and protection against wave action and tidal forces. They can be installed as a barrier between the revetment material and the underlying soil, preventing soil erosion and enhancing the overall stability of the revetment structure. Geotextiles also allow for proper drainage and filtration, reducing the risk of sediment buildup and enhancing the longevity of the revetment works.

- Q: Geotextile with glue can stick cement wall

- With the wind oil fine soaked, wipe with a rag off.

- Q: What are the common problems encountered during geotextile installation?

- Some common problems encountered during geotextile installation include improper placement or alignment, inadequate tensioning or anchoring, damage to the geotextile during installation, inadequate overlap or seam strength, and difficulties in handling or maneuvering the geotextile due to its size or weight.

- Q: JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

- Q: Waterproof geotextile market demand prospects?

- Supply geotextile, geomembrane, composite geomembrane and other geotechnical materials. Market prospects are excellent. Geotechnical material manufacturers to answer your questions

Send your message to us

Non-Woven Geotextile Drainage Fabric - Needle Punched Staple Fibers Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords