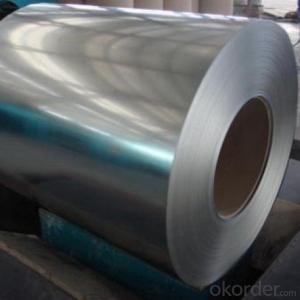

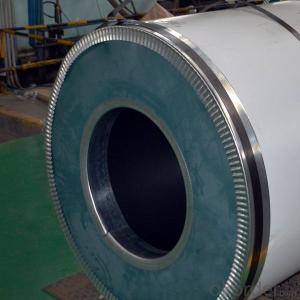

Stainless Steel Coils 304 Made In China Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Type | Stainless Steel Coil /Cold rolled Steel Coils |

Thinckness | 0.23mm-0.8mm |

Diameter | 115mm-560mm |

Quantity | as customer's requirement |

Finish | 2B,BA,HL,MIRROR,NO.1-NO.4,8K,and so on. |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Material | 201,202, 301,304,410,430,409 |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | 7-15 days |

Quality | Primary |

Productivity | 3000-4000 tons/month |

Note | We can produce other standard as the customers’ requirement |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- A continuous rolling mill is put in billions of dollars, but this is the rolling mill, and there are many gold furnaces. But the technical content of carbon steel with stainless steel is different, our country in more than 10 years ago the ability of continuous rolling of stainless steel is not high, equipment are imported, the stainless steel mill is dominated by 1219-1300, but also the development of national wide stainless steel 1500-2050, but the price is expensive at least thousands of dollars a ton, after all put the equipment to recover the cost, and the number of business orders is not much, it is difficult to find a spot on the market. Carbon steel countries have developed for many years, technology and equipment are mature, so the market has 1250 as production standards.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Railway infrastructure can utilize stainless steel sheets, as they offer numerous advantages. Stainless steel is a versatile and enduring material that is well-suited for railway applications. Its resistance to corrosion makes it suitable for outdoor and high humidity environments, which are commonplace in railway infrastructure. Stainless steel sheets can withstand severe weather conditions, such as extreme temperatures, rain, and UV radiation, without deteriorating or corroding. As a result, they are an excellent choice for railway tracks, bridges, tunnels, and other structures that are exposed to the elements. Moreover, stainless steel sheets possess an exceptional strength-to-weight ratio. This characteristic allows for the construction of lightweight yet robust railway infrastructure. Consequently, the overall structure's load is reduced, enabling easier transportation and installation. Stainless steel is also fire-resistant and can withstand significant impact, making it an ideal option for railway applications that prioritize safety. Furthermore, stainless steel sheets are effortless to clean and maintain, which is advantageous for railway infrastructure that necessitates regular upkeep. Their aesthetic appeal can be easily restored through polishing, ensuring a clean appearance. Additionally, stainless steel is recyclable, making it an environmentally friendly choice for sustainable railway construction. To summarize, due to their corrosion resistance, strength, durability, fire resistance, ease of maintenance, and sustainability, stainless steel sheets are indeed suitable for railway infrastructure.

- Q: Can stainless steel sheets be used for staircase railings?

- Yes, stainless steel sheets can be used for staircase railings. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor and indoor applications. Additionally, its sleek and modern appearance adds an aesthetic appeal to staircase railings.

- Q: Can stainless steel sheets be formed into different shapes?

- Stainless steel sheets possess the capability to assume diverse shapes. Such sheets are composed of a flexible material, which can be effortlessly altered using multiple techniques like bending, rolling, and stretching. Consequently, stainless steel sheets can be transformed into a wide array of configurations, encompassing curves, angles, cylinders, and intricate geometries. The pliability and ductility of these sheets render them exceptionally suitable for applications necessitating personalized shapes and designs. Moreover, owing to its resistance against corrosion and high temperatures, stainless steel is extensively utilized in shaping various forms within industries such as architecture, construction, automotive, and manufacturing.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Food preparation surfaces can indeed utilize stainless steel sheets. The reason behind stainless steel's popularity for such surfaces is its remarkable characteristics. Being non-porous, it avoids the absorption of any liquids or bacteria that can contaminate the food. Moreover, stainless steel exhibits resistance to corrosion, staining, and rusting, thereby ensuring its durability and longevity for food preparation surfaces. Furthermore, stainless steel can be easily cleaned due to its ability to withstand high temperatures and resistance to most cleaning agents. This fact makes it a hygienic option for food preparation surfaces, as it allows for thorough sanitization to prevent bacterial growth. In conclusion, stainless steel sheets provide a secure and practical alternative for food preparation surfaces.

- Q: What are the applications of stainless steel sheets?

- Due to their various beneficial properties, stainless steel sheets find a wide range of applications. Some common uses include: 1. Construction: Stainless steel sheets are widely utilized in the construction industry for various purposes. They provide durability, corrosion resistance, and an attractive appearance, making them suitable for cladding, roofing, wall panels, as well as structural components like beams, columns, and reinforcement bars. 2. Kitchenware: The production of kitchen appliances and utensils extensively involves stainless steel sheets. They are used to manufacture sinks, countertops, backsplashes, and cabinets. Stainless steel is preferred in the kitchen due to its hygienic properties, resistance to staining and corrosion, and ease of cleaning. 3. Automotive industry: Stainless steel sheets are utilized in the automotive industry for producing various components. They are used in the manufacturing of exhaust systems, mufflers, fuel tanks, and decorative trims. Stainless steel sheets offer corrosion resistance, heat resistance, and durability in harsh automotive environments. 4. Medical equipment: The medical field widely employs stainless steel sheets for the production of surgical instruments, implants, and medical equipment. The corrosion resistance and biocompatibility of stainless steel make it an ideal material for these applications. 5. Chemical processing: The chemical industry heavily relies on stainless steel sheets due to their corrosion resistance and ability to withstand high temperatures. They are used for manufacturing storage tanks, pipes, valves, and pressure vessels. Stainless steel sheets are preferred in chemical processing applications to prevent contamination and ensure process safety. 6. Energy and power generation: Stainless steel sheets are utilized in power plants, refineries, and other energy generation facilities. They are used in manufacturing boilers, heat exchangers, and condensers due to their high-temperature resistance, corrosion resistance, and strength. 7. Decorative applications: Stainless steel sheets are frequently employed in architectural and decorative applications. They are used for decorative panels, elevator doors, signage, and furniture. The versatility of stainless steel allows for various finishes and textures, making it a popular choice in interior and exterior design. In conclusion, stainless steel sheets are incredibly versatile and find numerous applications in various industries. Their corrosion resistance, durability, strength, and aesthetic appeal make them an ideal material for a wide range of purposes.

- Q: What are the different types of mirror finishes available for stainless steel sheets?

- There are several different types of mirror finishes available for stainless steel sheets, each offering a unique appearance and level of reflectivity. 1. #8 Mirror Finish: This is the most reflective and commonly used mirror finish. It has a highly polished surface with a mirror-like appearance, providing excellent reflectivity and clarity. This finish is achieved by using progressively finer grit abrasive compounds during the polishing process. 2. #7 Mirror Finish: This finish is slightly less reflective than the #8 mirror finish but still offers a high level of reflectivity. It has a smooth, shiny surface with minimal distortion, making it suitable for applications where a high level of reflectivity is desired. 3. #6 Mirror Finish: This finish has a moderately reflective surface with a slightly duller appearance compared to the #7 and #8 mirror finishes. It provides good reflectivity while hiding minor surface imperfections. It is often used in architectural applications where a balance between reflectivity and durability is required. 4. Satin Mirror Finish: This finish has a satin-like appearance with a low level of reflectivity. It has a smooth surface with a brushed texture, providing a subtle and sophisticated look. It is commonly used in decorative applications such as interior design or furniture. 5. Antique Mirror Finish: This finish is achieved by applying special chemical treatments to the stainless steel surface, creating a vintage or aged appearance. It has a reflective surface with a distorted and tarnished look, adding a unique and artistic touch to various applications. Overall, the choice of mirror finish depends on the desired level of reflectivity, aesthetic preferences, and specific application requirements.

- Q: Can stainless steel sheets be used for signage or lettering?

- Indeed, signage or lettering can make use of stainless steel sheets. Stainless steel, a remarkably durable and adaptable material, finds wide application in signage and various other fields. It possesses exceptional resistance to corrosion, rendering it suitable for both indoor and outdoor utilization. With stainless steel sheets, it becomes effortless to fabricate and shape them into diverse dimensions, enabling the creation of personalized signage and lettering designs. Moreover, stainless steel imparts a sleek and contemporary look, making it a captivating choice for signage in commercial or professional environments. In conclusion, stainless steel sheets offer a dependable and enduring solution for all your signage and lettering requirements.

- Q: Can stainless steel sheets be custom-cut?

- Stainless steel sheets have the capability to be tailored to specific sizes and dimensions. This adaptable material can be easily molded and formed to meet individual needs. The custom-cutting of stainless steel sheets is widely practiced across multiple industries, including construction, manufacturing, and fabrication. This procedure guarantees a precise fit for various purposes, such as architectural projects, machinery components, or kitchen equipment. Expert metal fabricators or specialized service providers commonly employ advanced techniques like laser cutting, waterjet cutting, or shearing to accurately customize stainless steel sheets according to desired specifications.

- Q: How can stainless steel sheets be cleaned and maintained?

- Stainless steel sheets are highly durable and resistant to corrosion, making them a popular choice for various applications. To maintain the appearance and functionality of stainless steel sheets, regular cleaning and proper maintenance are essential. Here are some steps to clean and maintain stainless steel sheets: 1. Start by removing any loose dirt or debris from the surface using a soft cloth or a brush. This step helps prevent scratching during the cleaning process. 2. Prepare a cleaning solution by mixing warm water with a mild detergent or dish soap. Avoid using abrasive cleaners or products containing chlorine, bleach, or ammonia, as they can damage the stainless steel surface. 3. Dip a soft cloth or sponge in the cleaning solution and gently scrub the stainless steel sheet in the direction of the grain. Avoid using excessive pressure to prevent scratching. 4. Rinse the sheet thoroughly with clean water to remove any residue from the cleaning solution. Ensure all soap or detergent is completely washed away. 5. Dry the stainless steel sheet using a soft, lint-free cloth. It is important to dry it thoroughly to prevent water spots or streaks from forming. 6. For stubborn stains or fingerprints, use a stainless steel cleaner or specialized stainless steel wipes. Follow the manufacturer's instructions on the product for best results. These cleaners can help restore the shine and remove any tough stains or marks. 7. To prevent scratches, avoid using abrasive materials such as steel wool or rough brushes when cleaning stainless steel sheets. Instead, use soft cloths or non-abrasive sponges. 8. Regularly inspect the stainless steel sheets for any signs of corrosion or damage. If any rust spots or pitting are noticed, use a stainless steel cleaner or passivation solution to restore the surface. Consult with a professional if the damage is extensive. 9. To maintain the appearance of the stainless steel sheet, it is recommended to wipe the surface regularly with a soft cloth or microfiber towel to remove dust, fingerprints, or other marks. By following these cleaning and maintenance steps, stainless steel sheets can retain their original shine, resist corrosion, and remain in excellent condition for an extended period.

Send your message to us

Stainless Steel Coils 304 Made In China Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords