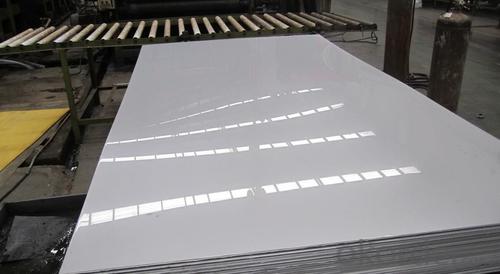

Stainless Steel sheet with smooth polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How do you prevent crevice corrosion in stainless steel sheets?

- To prevent crevice corrosion in stainless steel sheets, several key steps can be taken: 1. Design and fabricate properly: Ensure that the stainless steel sheets have smooth surfaces and minimal crevices during the design and fabrication process. This will decrease the likelihood of trapping stagnant solutions and minimize the possibility of crevice corrosion. 2. Regularly clean and maintain: Clean the stainless steel sheets on a regular basis to eliminate any debris or contaminants that may contribute to crevice corrosion. Mild detergents or specialized stainless steel cleaners can be used for this purpose. 3. Avoid exposure to corrosive environments: Limit the stainless steel sheets' exposure to corrosive surroundings, such as those containing chloride ions (e.g., saltwater). If exposure cannot be avoided, consider applying protective coatings or using higher-grade stainless steel alloys that are more resistant to crevice corrosion. 4. Environmental control: Maintain proper environmental conditions, including temperature, humidity, and pH levels, to minimize the risk of crevice corrosion. Monitoring and controlling these factors can create a less favorable environment for corrosion to occur. 5. Regular inspection and maintenance: Conduct routine inspections to identify any signs of crevice corrosion, such as discoloration, pitting, or rough surfaces. If any corrosion is detected, take immediate action to remove it and repair the affected area. By implementing these preventive measures, the risk of crevice corrosion in stainless steel sheets can be significantly reduced, ensuring their durability and performance.

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- A continuous rolling mill is put in billions of dollars, but this is the rolling mill, and there are many gold furnaces. But the technical content of carbon steel with stainless steel is different, our country in more than 10 years ago the ability of continuous rolling of stainless steel is not high, equipment are imported, the stainless steel mill is dominated by 1219-1300, but also the development of national wide stainless steel 1500-2050, but the price is expensive at least thousands of dollars a ton, after all put the equipment to recover the cost, and the number of business orders is not much, it is difficult to find a spot on the market. Carbon steel countries have developed for many years, technology and equipment are mature, so the market has 1250 as production standards.

- Q: Can stainless steel sheets be used for medical equipment?

- Indeed, medical equipment can utilize stainless steel sheets. The medical industry extensively employs stainless steel due to its remarkable resistance to corrosion, its durability, and its ease of cleaning. Surgical instruments, implants, medical devices, and equipment like sterilization trays, hospital beds, and operating room tables are commonly manufactured using stainless steel. As it does not react with bodily tissues or fluids, stainless steel is a secure and sanitary option for medical purposes. Moreover, it can endure numerous sterilization procedures without compromising its qualities, thus rendering it perfectly suited for hospitals and healthcare facilities.

- Q: Can stainless steel sheets be used for outdoor railings?

- Outdoor railings can indeed utilize stainless steel sheets. The reason behind the popularity of stainless steel for outdoor applications is its durability and resistance to corrosion. This material can endure exposure to various weather conditions, including rain, snow, and sunlight, without deteriorating or rusting. In addition to providing a sleek and modern appearance to outdoor spaces, stainless steel railings also offer strength and stability. Furthermore, they are low maintenance and easy to clean, making them an ideal choice for outdoor railings that may accumulate dirt, dust, or other debris. In conclusion, stainless steel sheets are an outstanding option for outdoor railings, as they combine aesthetic appeal with long-lasting performance.

- Q: Are stainless steel sheets suitable for laser cutting?

- Yes, stainless steel sheets are suitable for laser cutting.

- Q: What are the benefits of using embossed stainless steel sheets in elevator doors?

- There are several benefits of using embossed stainless steel sheets in elevator doors. Firstly, the embossed pattern adds a visually appealing and aesthetic element to the elevator doors, enhancing the overall appearance of the elevator interior. This can create a more luxurious and sophisticated atmosphere for passengers. Secondly, embossed stainless steel sheets are highly durable and resistant to scratches, dents, and corrosion. Elevator doors are subjected to constant use and can be easily damaged, but the use of embossed stainless steel sheets ensures that the doors maintain their pristine condition for a longer period of time. This durability also reduces maintenance and replacement costs over the lifespan of the elevator. Additionally, embossed stainless steel sheets provide a high level of hygiene. Stainless steel is inherently resistant to bacteria and germs, making it an ideal material for elevator doors. The embossed pattern further aids in hiding fingerprints and smudges, ensuring that the doors remain clean and sanitary with minimal maintenance. Moreover, embossed stainless steel sheets offer excellent fire resistance properties. Elevators are enclosed spaces, and in the unfortunate event of a fire, the use of embossed stainless steel sheets in the doors can help contain the flames and prevent the spread of fire, providing an added level of safety for passengers. Lastly, embossed stainless steel sheets are easy to clean and maintain. With a smooth surface and resistance to stains and dirt, these sheets can be easily wiped down with a mild cleaner, keeping the elevator doors looking pristine and reducing the amount of time and effort required for cleaning. In summary, the benefits of using embossed stainless steel sheets in elevator doors include enhanced aesthetics, durability, hygiene, fire resistance, and ease of maintenance. These advantages make embossed stainless steel sheets a popular choice for elevator manufacturers and building owners alike.

- Q: Seeking stainless steel plate 304 material and 304j material what is the difference?

- 304 applications: petroleum, chemical, pharmaceutical, food, machinery, aerospace, construction, military, hardware, boilers, gas, plumbing and heating equipment, ships, power plants and other industries.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer several benefits. Firstly, they provide a sleek and modern aesthetic appeal, making them a popular choice for interior and architectural design. Additionally, the reflective surface of these sheets creates the illusion of a larger space, making them ideal for small areas. Mirror-finish stainless steel also has superior corrosion resistance, making it a durable option for outdoor applications. The smooth surface is easy to clean and maintain, reducing the need for frequent upkeep. Finally, mirror-finish stainless steel sheets are often used in food processing and medical industries due to their hygienic properties and ability to resist bacterial growth.

- Q: What is the maximum length available for stainless steel sheets?

- The maximum length for stainless steel sheets can differ based on the supplier and the grade of stainless steel in question. Typically, stainless steel sheets can be found in lengths that span from 96 inches (8 feet) to 240 inches (20 feet). In certain circumstances or upon request, suppliers may provide even lengthier sheets, reaching up to 300 inches (25 feet) for particular applications. To ascertain the maximum length available for the specific stainless steel sheet you need, it is crucial to consult with the supplier.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are highly suitable for oil and gas equipment. Stainless steel has excellent corrosion resistance, high strength, and durability, making it an ideal choice for harsh environments and corrosive substances encountered in the oil and gas industry. Additionally, stainless steel's heat resistance and low maintenance requirements further contribute to its effectiveness in this field.

Send your message to us

Stainless Steel sheet with smooth polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords