Stainless Steel sheet with polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

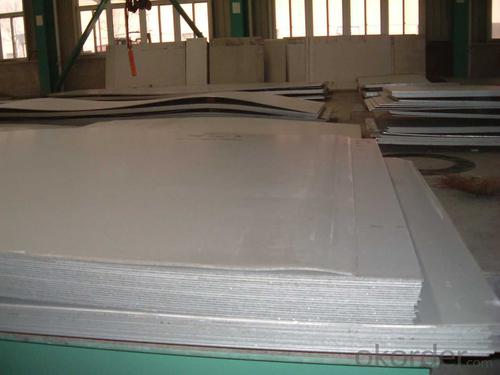

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

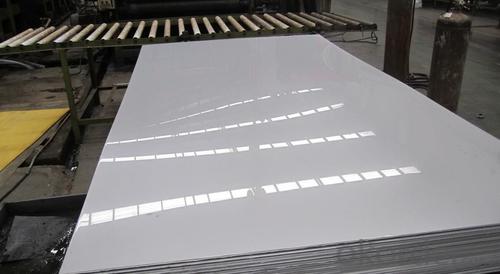

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for architectural louvers or screens?

- Yes, stainless steel sheets are suitable for architectural louvers or screens due to their durability, corrosion resistance, and aesthetic appeal. They provide a sleek and modern look while also offering protection against weather elements, making them a popular choice for architectural applications.

- Q: Can stainless steel sheets be used for elevator mirrors?

- Certainly! Elevator mirrors can indeed be made using stainless steel sheets. Stainless steel, being both durable and versatile, is a favored material for elevator interiors due to its sleek and polished look. By polishing stainless steel sheets to a mirror-like finish, they can be effectively utilized as reflective surfaces for elevator mirrors. Furthermore, stainless steel's resistance to corrosion makes it well-suited for the humid and frequently challenging conditions typically encountered in elevators.

- Q: What is the difference between stainless steel sheets and plates?

- Stainless steel sheets and plates, widely utilized across various industries and applications, possess distinct dissimilarities. Firstly, concerning thickness, sheets are generally thinner compared to plates. Sheets typically range from 0.4mm to 4mm, whereas plates commence at 4mm and extend to several inches. Secondly, their sizes differ. Sheets are commonly available in standard dimensions of 4ft x 8ft or 5ft x 10ft, while plates usually come in larger sizes and can be tailored to specific measurements. Plates are commonly employed in heavy-duty applications, necessitating enhanced strength and durability. Thirdly, weight plays a role in distinguishing the two. Due to the variance in thickness, plates generally possess greater weight than sheets. This characteristic renders plates more suitable for weight-bearing applications, such as construction, shipbuilding, or industrial equipment. Fourthly, the applications of sheets and plates differ. Stainless steel sheets are often employed for decorative purposes, architectural applications, and smaller-scale projects like kitchen backsplashes or countertops. Conversely, plates are favored for structural components, machinery parts, and load-bearing applications, like bridges, tanks, or pressure vessels. Lastly, cost distinguishes sheets from plates. Stainless steel plates are typically more expensive than sheets due to their larger size and increased thickness. Sheets, being thinner and smaller, are usually more cost-effective and readily accessible. In summary, the key distinctions between stainless steel sheets and plates encompass their thickness, size, weight, applications, and cost. It is imperative to consider these factors when selecting the appropriate material for a specific project or application.

- Q: Are stainless steel sheets suitable for chemical processing plants?

- Yes, stainless steel sheets are highly suitable for chemical processing plants. Stainless steel is known for its excellent corrosion resistance, making it ideal for handling various chemicals and corrosive substances commonly found in chemical processing plants. Additionally, stainless steel sheets are also durable, hygienic, and easy to clean, making them a reliable choice for maintaining a clean and safe working environment in such facilities.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets require special handling during installation to ensure their proper installation and to prevent damage. Some important considerations include using proper lifting equipment, ensuring a clean and dry surface, avoiding contact with other metals to prevent galvanic corrosion, and following the manufacturer's guidelines for installation and maintenance.

- Q: Can stainless steel plate spray paint?

- Topcoat. Because it is in the open, one hand paint with good weather resistance, on the other hand, it is very difficult to use paint, most of the prison film so that polyurethane paint is a two-component paint curing agent, without baking, the room temperature with the curing agent can be cured thoroughly. As the old brand is very good.

- Q: What is the water resistance of stainless steel sheets?

- The water resistance of stainless steel sheets is typically high due to their nonporous nature and corrosion-resistant properties.

- Q: What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade and type of stainless steel, but it generally ranges from 0.5 to 6 millimeters (mm) or even thicker for certain applications.

- Q: What brand of stainless steel plate is good?

- It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

Send your message to us

Stainless Steel sheet with polishing treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords