Stainless Steel Sheet with prime quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet with prime quality

Features Stainless Steel Sheet with prime quality:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information Stainless Steel Sheet with prime quality:

1. Steel grade: 321

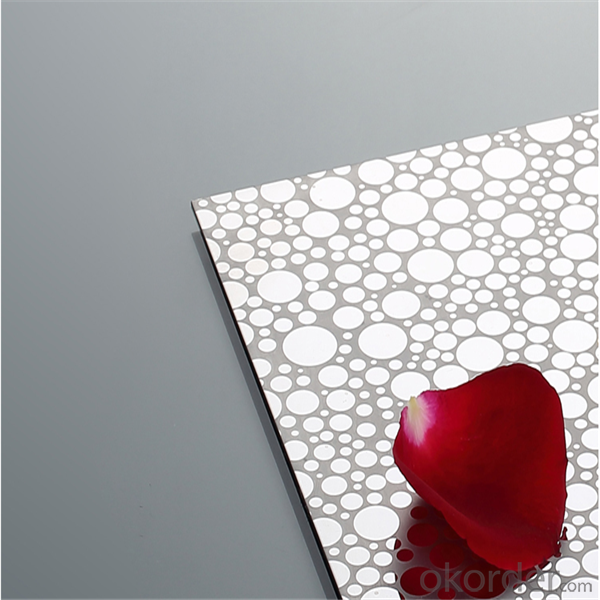

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

1. Specifications about Stainless Steel Sheet with prime quality

Commodity | Stainless Steel Sheet with prime quality |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 5 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

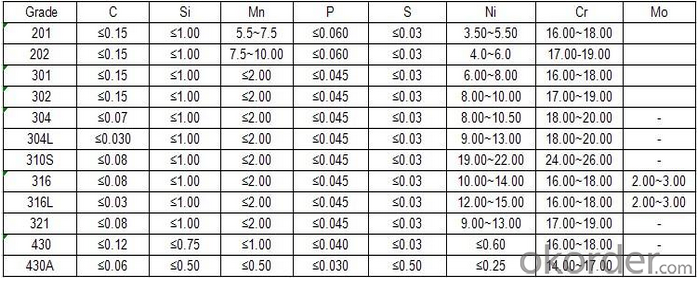

2. Chemical Composition about stainless steel sheet

- Q: What are the different types of stainless steel sheets?

- There is a variety of stainless steel sheets to choose from, each with its own unique properties and uses. Here are some of the most commonly used types: 1. Austenitic stainless steel sheets are widely used due to their excellent corrosion resistance and high ductility. They are non-magnetic and can be easily formed, making them suitable for various applications like kitchen equipment, architectural structures, and automotive components. 2. Ferritic stainless steel sheets have a lower chromium content compared to austenitic stainless steel. They offer good corrosion resistance in specific environments and are often used in applications that require high temperature resistance, such as industrial ovens and exhaust systems. 3. Martensitic stainless steel sheets are known for their high strength and hardness. They are magnetic and provide good corrosion resistance, making them suitable for applications that require both strength and corrosion resistance, like knives, turbine blades, and valve parts. 4. Duplex stainless steel sheets combine the properties of both austenitic and ferritic stainless steels. They have excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel is commonly used in industries such as chemical processing, oil and gas, and marine environments. 5. Precipitation-hardening stainless steel sheets are heat treatable, offering high strength and excellent corrosion resistance. They are commonly used in applications that require a high strength-to-weight ratio, such as aerospace components, springs, and shafts. These examples highlight the variety of stainless steel sheets available. The choice of which type to use depends on specific application requirements, considering factors such as corrosion resistance, strength, formability, and cost.

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Yes, stainless steel sheets are highly suitable for food processing and medical applications. Stainless steel is a popular choice in these industries due to its numerous beneficial properties. Firstly, stainless steel is resistant to corrosion, making it ideal for environments where hygiene and cleanliness are of utmost importance, such as food processing plants and medical facilities. Secondly, stainless steel is a non-porous material, meaning it does not absorb or retain bacteria, germs, or odors. This makes it easy to clean and maintain high levels of sanitation, crucial in food processing and medical settings where contamination must be minimized. Additionally, stainless steel has excellent strength and durability, allowing it to withstand harsh conditions, heavy use, and frequent cleaning without deteriorating. This makes stainless steel sheets a reliable and long-lasting choice for these demanding applications. Furthermore, stainless steel is non-reactive with food and many medical substances, ensuring that it does not leach any harmful chemicals or contaminants into the products being processed or the patients being treated. This is crucial for maintaining the safety and integrity of both food and medical materials. In conclusion, stainless steel sheets are highly suitable for food processing and medical applications due to their corrosion resistance, non-porous nature, strength, durability, and non-reactive properties. Choosing stainless steel ensures the highest standards of hygiene, cleanliness, and safety in these industries.

- Q: Can stainless steel sheets be used for heat transfer applications?

- Yes, stainless steel sheets can be used for heat transfer applications. Stainless steel has excellent thermal conductivity, making it suitable for transferring heat efficiently between two surfaces or mediums. It is commonly used in heat exchangers, cookware, and other applications where heat transfer is essential.

- Q: What are the advantages of using stainless steel sheets?

- There are several advantages to using stainless steel sheets in various applications. Firstly, stainless steel is known for its exceptional corrosion resistance. It is highly resistant to rust and stains, making it a suitable choice for environments where moisture and other corrosive substances are present. This durability ensures that stainless steel sheets maintain their aesthetic appeal and structural integrity over time. Secondly, stainless steel is incredibly strong and durable. It has a high tensile strength, meaning it can withstand heavy loads and resist deformation. This makes stainless steel sheets ideal for applications that require robustness, such as construction, automotive, and industrial projects. Thirdly, stainless steel is hygienic and easy to clean. It has a non-porous surface that prevents the growth of bacteria and other microorganisms, making it a popular choice for food processing equipment, medical tools, and healthcare facilities. Additionally, stainless steel sheets are easy to maintain, as they can be wiped clean or sterilized without damaging the material. Moreover, stainless steel sheets are aesthetically pleasing and versatile. They have a sleek and modern appearance that can enhance the visual appeal of architectural designs, interior decorations, and kitchen appliances. Stainless steel sheets come in a variety of finishes, such as brushed, mirror, or textured, allowing for customization to suit specific design preferences. Lastly, stainless steel is an environmentally friendly material. It is 100% recyclable, which means it can be reused and repurposed without any loss in quality or performance. This makes stainless steel sheets a sustainable choice, reducing the need for new raw materials and minimizing waste. In conclusion, the advantages of using stainless steel sheets include excellent corrosion resistance, strength and durability, hygienic properties, aesthetic appeal, and environmental sustainability. These characteristics make stainless steel sheets a versatile and reliable choice for a wide range of applications.

- Q: What's the drill for stainless steel?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To regain the luster or polish on stainless steel sheets, there are several approaches you can attempt: 1. Warm water and soap cleanse: Initiate the process by washing the stainless steel sheets with warm water and a mild dish soap. Employ a soft cloth or sponge to delicately scrub the surface, then rinse it with clean water and meticulously dry it with a clean cloth. This procedure should eliminate any dirt or grime that is dimming the shine. 2. Vinegar solution: In case the stainless steel sheets possess obstinate stains or lackluster spots, you can experiment with a vinegar solution. Combine equal parts of white vinegar and water in a spray bottle, then spritz the solution onto the surface. Allow it to sit for a few minutes, then wipe it away with a soft cloth. Vinegar aids in stain removal and rejuvenates the shine of stainless steel. 3. Baking soda paste: For more stubborn stains or scratches on the stainless steel sheets, you can concoct a paste using baking soda and water. Blend an ample amount of baking soda with water until a thick paste forms, then apply it to the stained areas. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain. Rinse with water and meticulously dry it. 4. Stainless steel cleaner: There are commercially available stainless steel cleaners that are specifically formulated to restore the shine and finish of stainless steel. Adhere to the instructions on the cleaner and administer it to the surface using a soft cloth or sponge. Gently rub in the direction of the grain and rinse with water. To prevent water spots, ensure thorough drying. Always remember to test any cleaning method or solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This precaution will help ensure that the method or solution does not cause any damage or discoloration.

- Q: Can stainless steel sheets be used for outdoor signage?

- Yes, stainless steel sheets can be used for outdoor signage. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand harsh weather conditions, making it a suitable material for outdoor applications such as signage. Additionally, stainless steel sheets offer a sleek and modern appearance, making them an attractive option for outdoor signage.

- Q: Are stainless steel sheets suitable for water treatment applications?

- Yes, stainless steel sheets are highly suitable for water treatment applications. Stainless steel is known for its excellent corrosion resistance, making it the ideal choice for environments where water and moisture are present. It is resistant to rust, staining, and pitting, which ensures the longevity and durability of the sheets in water treatment facilities. Stainless steel sheets also offer hygienic properties, as they are easy to clean and maintain. This is crucial in water treatment applications where cleanliness and sanitation are of utmost importance. Additionally, stainless steel is non-reactive with water, meaning it does not leach harmful substances into the water being treated. Furthermore, stainless steel sheets are strong and can withstand high pressures and temperatures. This is critical in water treatment processes that involve filtration, disinfection, and other treatment methods that may require intense conditions. Overall, stainless steel sheets are an excellent choice for water treatment applications due to their corrosion resistance, hygienic properties, strength, and durability. They provide a reliable and long-lasting solution for various components in water treatment facilities, including tanks, pipes, valves, and other equipment.

- Q: How do you prevent pitting corrosion on stainless steel sheets?

- To prevent pitting corrosion on stainless steel sheets, it is important to maintain a clean and dry surface, avoid exposure to corrosive environments or chemicals, and promptly clean off any contaminants or deposits. Additionally, applying a protective coating or passivation treatment can help enhance the corrosion resistance of the stainless steel sheets. Regular inspections and maintenance are also crucial to detect and address any signs of pitting corrosion early on.

- Q: Stainless steel wire drawing without fingerprints, what principle?

- As for sandblasting, the surface roughness is higher than the wire drawing, and the stainless steel has no gloss (which makes the customer fail to see the stainless steel parts and sometimes lower the grade). Liquid blasting is recommended to achieve relatively better surface treatment results.Commercial kitchen experts completely hand, no copy paste. Please give favorable comments.

Send your message to us

Stainless Steel Sheet with prime quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords