Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hotdip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

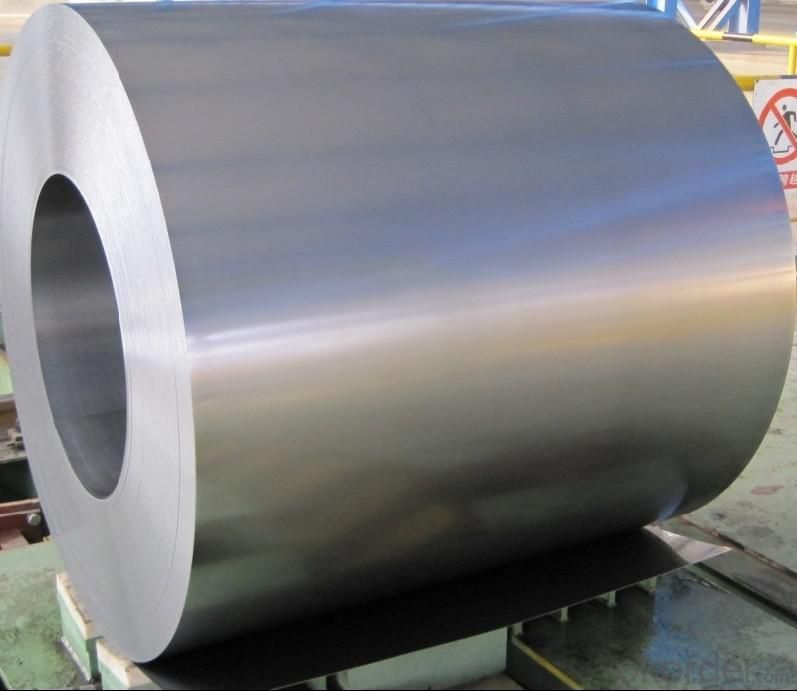

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for elevator flooring or platforms?

- Yes, steel sheets can be used for elevator flooring or platforms. Steel is a durable and strong material that can support the weight and traffic typically experienced in elevators. It is commonly used in the construction of elevator floors and platforms due to its resilience and safety features.

- Q: What are the different methods of cutting steel sheets?

- There are several different methods of cutting steel sheets, including traditional methods such as shearing, sawing, and plasma cutting, as well as more modern techniques such as laser cutting and waterjet cutting. Each method has its own advantages and limitations, and the choice of method depends on factors such as the thickness and type of steel, desired precision, and production volume.

- Q: Can steel sheets be used for insulation cladding?

- Typically, insulation cladding does not involve the use of steel sheets. Instead, materials like foam boards, mineral wool, or fiberglass are commonly chosen for their thermal insulation properties. These materials are effective in minimizing heat transfer and enhancing energy efficiency. Conversely, steel sheets are more frequently utilized for structural purposes or as a protective layer owing to their robustness and durability. Though steel sheets can offer some protection, they lack the requisite insulation properties required to effectively prevent the transfer of heat or cold. Consequently, it is advisable to employ suitable insulation materials specifically designed for cladding purposes.

- Q: What are the limitations of using steel sheets?

- The use of steel sheets in various applications comes with several limitations. To begin with, steel sheets are considerably heavy compared to other materials, which can present challenges in terms of transportation and installation. This weight can also hinder their usage in industries like aerospace or automotive, where weight reduction is crucial. Secondly, steel sheets are prone to corrosion, particularly when exposed to moisture and chemicals. Without proper protection, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often necessary to prevent corrosion, which adds to the overall cost and maintenance requirements of using steel sheets. Another limitation is the limited flexibility of steel sheets, making it difficult to mold or shape them into complex forms. This restricts their application in areas where intricate designs or curved surfaces are needed, such as the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, necessitating additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource, and their production has a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In conclusion, while steel sheets are widely valued for their strength and durability, it is important to consider their limitations, including their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact, when selecting materials for specific applications.

- Q: What is the bending radius for steel sheets?

- The bending radius of steel sheets is influenced by several factors, including the sheet's thickness, the type of steel utilized, and the particular application at hand. Typically, a widely accepted guideline suggests employing a bending radius that is no less than twice the thickness of the steel sheet. Nevertheless, this figure can fluctuate depending on the specific demands and constraints of the undertaking. It is crucial to seek guidance from engineering and fabrication specialists experienced in handling steel sheets to ascertain the suitable bending radius for a specific application.

- Q: How are steel sheets packaged for shipping?

- Steel sheets are typically packaged for shipping by being stacked on wooden pallets and secured with steel or plastic strapping. Additionally, they may be further protected by being wrapped in plastic or covered with a cardboard or wooden crate for added stability and protection during transportation.

- Q: What does "steel plate 10t" mean in the specification column of engineering material?

- 10T refers to the steel plate thickness of 10mm.Steel plate is made of molten steel, cooled and compressed into flat steel.The steel plate is flat, rectangular, and can be rolled directly or cut from a wide strip of steel.

- Q: Are the steel sheets suitable for water tank fabrication?

- Steel sheets are indeed appropriate for the fabrication of water tanks. Due to their strength and durability, steel can tolerate the pressure exerted by water and offer vital structural reinforcement. Moreover, when adequately coated or treated, steel proves resistant to corrosion, thereby guaranteeing the purity and unspoiled nature of the stored water. Additionally, steel sheets are highly malleable and can be effortlessly shaped and molded to meet precise design specifications for water tanks. Consequently, steel sheets emerge as a dependable and widely employed material choice for the construction of water tanks.

- Q: Do steel sheets require any surface treatment before installation?

- Yes, steel sheets typically require surface treatment before installation. This is done to improve the durability and appearance of the steel, as well as to protect it from corrosion. The most common surface treatment methods for steel sheets include galvanization, painting, and powder coating. Galvanization involves applying a protective zinc coating to the steel, which helps to prevent rust and corrosion. Painting and powder coating, on the other hand, involve applying a protective layer of paint or powder to the steel surface. These surface treatments not only provide aesthetic appeal but also enhance the steel's resistance to environmental factors such as moisture, chemicals, and UV radiation. Therefore, it is recommended to apply suitable surface treatment to steel sheets before installation to ensure their longevity and performance.

- Q: How do steel sheets perform in terms of wear resistance?

- Steel sheets generally perform very well in terms of wear resistance. Steel is known for its strength and durability, and steel sheets are no exception. They are able to withstand heavy loads, abrasion, and impact, making them suitable for a wide range of applications where wear resistance is crucial. Additionally, steel sheets can be further enhanced with surface treatments or coatings to improve their wear resistance even more. Overall, steel sheets are a popular choice for industries that require materials capable of withstanding wear and tear over extended periods of time.

Send your message to us

Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords