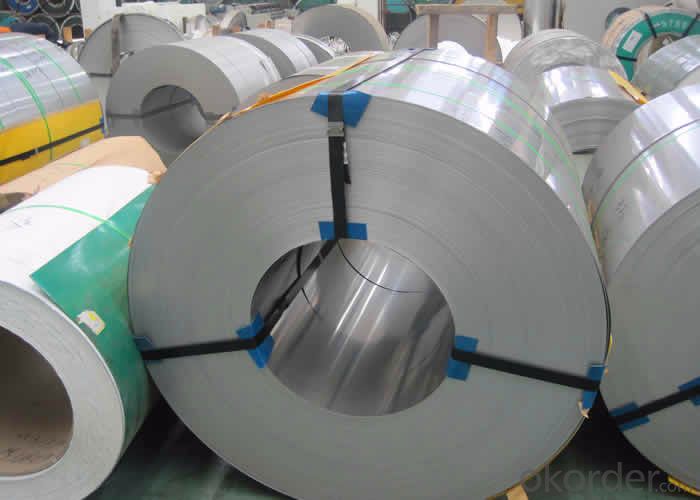

Different Grade Steel Sheet Coil Plate for choice

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coils and Sheets

Features of Stainless Steel Coils and Sheets:

· Accurate dimension

· Suitable for heavy duty operation

· Minimum maintenance

Specifications of Stainless Steel Coils:

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.4mm-50mm

4. Width: 1000/1219/1500/1800mm

5. Length: min 1m

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Packing Information of Stainless Steel Coils and Sheets:

Please don’t worry that our products are packed, stored, transported according to the international regulation. We do care about the quality of our products; even some little details are paid attention to.

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

Plus, our storage racks are made of wood. Other kinds of metals are settled in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented.

Applications of Stainless Steel Coils and Sheets:

1.Automotive:Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers

4. Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

Technical notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: Are stainless steel sheets resistant to organic acids?

- Yes, stainless steel sheets are generally resistant to organic acids.

- Q: Can stainless steel sheets be used for water treatment equipment?

- Yes, stainless steel sheets can be used for water treatment equipment. Stainless steel is highly resistant to corrosion and oxidation, making it an ideal material for water treatment applications. It is commonly used for tanks, pipes, valves, and other components in water treatment systems. Stainless steel's durability and hygienic properties make it suitable for handling various types of water, including drinking water, wastewater, and industrial process water. Additionally, stainless steel is easy to clean and maintain, ensuring the longevity and efficiency of water treatment equipment.

- Q: How do I determine the hardness of stainless steel sheets?

- To determine the hardness of stainless steel sheets, there are a few methods you can use. One common method is the Rockwell hardness test, which measures the depth of penetration of an indenter into the material. The Rockwell scale has different scales depending on the material, so you will need to use the appropriate scale for stainless steel. To perform the Rockwell hardness test, you will need a Rockwell hardness tester and a diamond or tungsten carbide indenter. Start by placing the stainless steel sheet on a flat, stable surface. Then, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. Once the load has been applied and released, the hardness value will be displayed on the Rockwell hardness tester's dial or digital display. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to note that the Rockwell hardness test provides a relative measurement of hardness and does not necessarily reflect the material's physical properties. Additionally, the hardness of stainless steel can vary depending on factors such as the alloy composition, heat treatment, and manufacturing process. Therefore, it is recommended to consult the material's specifications or conduct additional tests to obtain more accurate and comprehensive information about the stainless steel sheet's hardness.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- Stainless steel sheets can be finished with various edge treatments to achieve different appearances and functionalities. These finishes serve to enhance the sheet's aesthetics, protect against sharp edges and potential corrosion. 1. Mill Finish: The standard edge finish for stainless steel sheets is the raw, untreated edge produced during manufacturing. While it may have a slightly rough or uneven appearance, it is functional and commonly used in industrial applications. 2. Deburred Edges: To eliminate any sharp or jagged edges, the stainless steel sheet can undergo deburring. This involves grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly chosen in safety-sensitive applications like food processing or medical equipment. 3. Rounded Edges: Rounded edges are achieved by utilizing a rounding tool to smooth out the sharp corners of the stainless steel sheet. This finish not only enhances the sheet's aesthetics but also reduces the risk of injury from sharp edges. Rounded edges are often favored for architectural or decorative purposes. 4. Beveled Edges: By cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees, beveled edges are created. This chamfered edge adds a sleek and modern appearance to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to achieve a smooth and mirror-like finish. This edge treatment adds a touch of elegance and sophistication, making it suitable for high-end architectural or decorative applications. To sum up, stainless steel sheets can be finished with mill finish, deburred edges, rounded edges, beveled edges, or polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q: What are the benefits of using laser-cut stainless steel sheets?

- The benefits of using laser-cut stainless steel sheets include precision and accuracy in cutting, clean and smooth edges, high-quality finish, versatility in design options, increased productivity and efficiency, and cost-effectiveness in the long run due to reduced material waste and minimal post-processing requirements.

- Q: Is there any magnetism in 304 stainless steel?

- Stainless steel friends are many, there are some differences in color, but not very good to distinguish. Can be judged according to the magnetic (magnet test): magnetic was 202 (ferritic stainless steel) magnetic or nonmagnetic small is 304 (stainless steel), are generally magnetic, but strength difference.

- Q: Are stainless steel sheets scratch-resistant?

- Yes, stainless steel sheets are scratch-resistant due to their high durability and resistance to wear and tear.

- Q: What are the different types of textured patterns available for stainless steel sheets?

- There are several different types of textured patterns available for stainless steel sheets, each offering a unique aesthetic and functional appeal. Some of the commonly found textured patterns include: 1. Diamond Pattern: This pattern features a raised diamond-shaped design, giving the sheet a beautiful and distinct look. It is commonly used for decorative purposes, offering a sophisticated and modern appearance. 2. Linen Pattern: The linen pattern resembles a woven fabric, with a textured surface that mimics the look of linen cloth. It provides a subtle, elegant, and versatile option for various applications, including architectural and interior design. 3. Quilted Pattern: As the name suggests, the quilted pattern resembles the stitching of a quilt. It creates a three-dimensional effect that adds depth and visual interest to stainless steel sheets. This pattern is often used in automotive, interior design, and decorative applications. 4. Checker Plate Pattern: Also known as diamond plate or tread plate, the checker plate pattern consists of raised diamond-shaped indents on the surface. It provides enhanced slip resistance and is commonly used for flooring, stair treads, and other industrial applications. 5. Bead Blast Pattern: The bead blast pattern involves a sandblasting technique that creates a consistent, matte finish with a slightly textured surface. It offers a modern, sleek appearance, making it popular for architectural and decorative applications. 6. Hammered Pattern: The hammered pattern replicates the texture of a hammered metal surface. It provides a unique and rustic look, often seen in kitchen appliances, countertops, and decorative accents for a vintage or industrial-style design. 7. Leather Grain Pattern: This pattern imitates the texture of leather, offering a soft, luxurious appearance. It is commonly used in high-end interior design projects, such as wall panels, furniture, and elevator interiors. These are just a few examples of the many textured patterns available for stainless steel sheets. Each pattern has its own distinct characteristics, allowing designers and manufacturers to choose the one that best suits their specific requirements and desired aesthetic.

- Q: Are stainless steel sheets resistant to chemicals?

- Generally, chemicals do not pose a problem for stainless steel sheets. Stainless steel is famous for its ability to resist corrosion, which is why it is widely used in industries like chemical processing, pharmaceuticals, and food processing. The presence of elements like chromium and nickel in stainless steel forms a protective layer on its surface, preventing most chemicals from penetrating. However, it's important to note that the resistance to chemicals may vary depending on the grade and composition of the stainless steel used. In highly aggressive environments or when dealing with specific chemicals, it's advisable to consult a materials engineer or refer to compatibility charts to ensure the best stainless steel grade is chosen.

- Q: Can stainless steel sheets be used for electrical enclosures?

- Stainless steel sheets are indeed suitable for electrical enclosures. With their highly durable and corrosion-resistant properties, they offer excellent safeguarding for electrical components. Their strength allows them to endure harsh environmental conditions, making them applicable for both indoor and outdoor uses. Furthermore, stainless steel exhibits good conductivity and efficient heat dissipation, ensuring optimal temperature control within the enclosure. These remarkable qualities make stainless steel sheets a dependable option for electrical enclosures, guaranteeing enduring performance and protection for the enclosed equipment.

Send your message to us

Different Grade Steel Sheet Coil Plate for choice

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords