color coated roofing sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

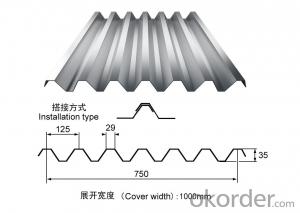

color coated roofing sheet

1) Quality Standard & Grade: JIS G3302, SGCC / ASTM 653M CQ/ EN10142 DX51D+Z

2) Zinc coating : 50g/m2

3) color film thickness:20micro(doubled)

4) Surface Treatment: chromated , non oiled, skin passed

5) Packing: export standard packing,packed with moisture resistant paper and metal

wrapping,securely tied for export,on metal skids) Country of Origin :

SIZE:0.25mm*840mm(1000mmBEFORE)*3660MM

COLOR:BLUE

- Q: Can the steel sheets be easily folded or creased?

- No, steel sheets cannot be easily folded or creased. Steel is a strong and rigid material that requires a significant amount of force to be bent or creased. It is commonly used in construction and manufacturing due to its durability and resistance to deformation. However, if the steel sheets are thin enough, they may be malleable enough to be bent or creased with the appropriate tools and techniques.

- Q: How are steel sheets protected during storage in humid environments?

- Steel sheets are protected during storage in humid environments by applying a protective coating, such as a layer of oil or zinc, which acts as a barrier against moisture and prevents corrosion. Additionally, proper packaging and storage techniques, such as using moisture-absorbing materials and maintaining appropriate temperature and ventilation, are employed to minimize the exposure of steel sheets to humidity.

- Q: How do steel sheets perform in terms of chemical resistance?

- Steel sheets generally have good chemical resistance due to their high corrosion resistance. However, their exact performance can vary depending on the specific type of steel and the chemicals they come into contact with.

- Q: Can steel sheets be used for food processing or storage?

- Yes, steel sheets can be used for food processing or storage. Steel is a durable and hygienic material that is commonly used in the food industry due to its resistance to corrosion, easy cleaning, and ability to maintain proper food safety standards.

- Q: What is the typical thickness tolerance of a steel sheet?

- The typical thickness tolerance of a steel sheet can vary depending on the specific grade of steel and the manufacturing process used. However, in general, the typical thickness tolerance for a steel sheet is around ±0.005 to ±0.010 inches.

- Q: Are the steel sheets suitable for HVAC ductwork?

- Yes, steel sheets are suitable for HVAC ductwork due to their durability, strength, and resistance to heat and corrosion.

- Q: What kind of steel plate is HIC?

- Is suitable for use in acidic environment, hydrogen sulfide corrosion resistance of the steel plate. Also known as hydrogen or hydrogen resistant steel, generally pressure vessel or pipe steel.

- Q: Are steel sheets suitable for water tanks or reservoirs?

- Yes, steel sheets are suitable for water tanks or reservoirs. Steel is a durable and strong material that can withstand the weight of water and provide long-lasting protection against corrosion. Additionally, steel tanks can be easily customized to meet specific size requirements and can be coated to further enhance their resistance to water and environmental factors.

- Q: Are steel sheets resistant to extreme weather conditions?

- Yes, steel sheets are generally resistant to extreme weather conditions. They are known for their durability and ability to withstand harsh elements such as rain, snow, high winds, and even extreme temperatures. Steel sheets are often used in construction and roofing applications precisely due to their excellent weather resistance properties.

- Q: What is the hardness of the steel sheets?

- The hardness of steel sheets can vary depending on the specific grade and manufacturing process, but generally, steel sheets have a high hardness level due to their strong composition.

Send your message to us

color coated roofing sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords