FDCORRIGATED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORRIGATED SHEET 7210701000

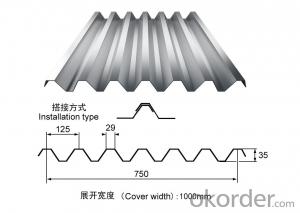

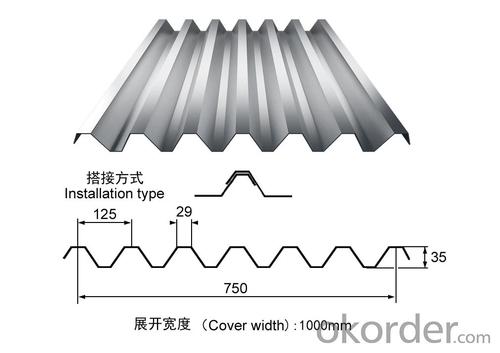

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

In continuous units in cold rolled steel strip, galvanized steel (electro galvanized and hot dip galvanized) as substrate, after surface pretreatment (degreasing and science processing), using the method of roll coating, coated with a layer or multi-layer liquid coating of plate, after baking and cooling income is the coating steel plate. Because the coating can have a variety of colors, on the habits of the coated steel sheet is called color coating steel plate. Because the coating is carried out before the sheet metal forming, in foreign countries which is called pre coating plate.

Color coated steel sheet is an organic coating coating on the steel surface, it has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, easy processing molding, but also allows the user to reduce costs, reduce pollution.

From the United States in 1935 to establish the first continuously coated steel line to begin, color coated steel plate has been widely applied, the current color coated plate varieties, about more than 600 kinds, the advantages of color coated sheet and organic polymer and steel plate of the two, which has good colorability, organic polymer molding, corrosion resistance and decorative, and steel plate with high strength and easy processing, can easily be punching cutting, bending, deep drawing processing. Made this makes organic coated steel sheet products have excellent practical, decorative, workability, durability.

- Q: What are the limitations of using steel sheets?

- The use of steel sheets in various applications comes with several limitations. To begin with, steel sheets are considerably heavy compared to other materials, which can present challenges in terms of transportation and installation. This weight can also hinder their usage in industries like aerospace or automotive, where weight reduction is crucial. Secondly, steel sheets are prone to corrosion, particularly when exposed to moisture and chemicals. Without proper protection, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often necessary to prevent corrosion, which adds to the overall cost and maintenance requirements of using steel sheets. Another limitation is the limited flexibility of steel sheets, making it difficult to mold or shape them into complex forms. This restricts their application in areas where intricate designs or curved surfaces are needed, such as the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, necessitating additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource, and their production has a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In conclusion, while steel sheets are widely valued for their strength and durability, it is important to consider their limitations, including their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact, when selecting materials for specific applications.

- Q: Can steel sheets be used for water tanks or reservoirs?

- Yes, steel sheets can be used for water tanks or reservoirs. Steel is a durable and strong material that is commonly used for constructing water tanks due to its ability to withstand high pressure and resist corrosion. Additionally, steel tanks can be easily fabricated and customized to meet specific size and capacity requirements. However, proper coating and maintenance are necessary to prevent rusting and ensure the longevity of the tank.

- Q: Are steel sheets resistant to warping under heat?

- Yes, steel sheets are highly resistant to warping under heat. Steel has a high melting point and excellent thermal conductivity, which helps it maintain its structural integrity even at high temperatures. This makes steel sheets a suitable choice for applications where heat resistance is crucial, such as in construction, automotive, and industrial manufacturing.

- Q: How do steel sheets perform in terms of light reflection?

- Steel sheets have a high level of light reflection due to their smooth and polished surface, making them an excellent choice for applications that require good visibility and illumination.

- Q: What are the common thicknesses available for steel sheets?

- The common thicknesses available for steel sheets typically range from 0.5 mm to 25 mm, depending on the specific application and industry requirements.

- Q: What are the different types of steel sheet finishes for architectural applications?

- There are several different types of steel sheet finishes that are commonly used for architectural applications. These finishes not only enhance the aesthetic appeal of the steel sheets but also provide protection against corrosion and other environmental factors. 1. Mill Finish: This is the most basic type of finish, where the steel sheet is left as it comes from the mill. It has a dull, gray appearance and is typically used for applications where aesthetics are not a priority. 2. Brushed Finish: Also known as a satin finish, this type of finish is achieved by brushing the steel sheet with a fine abrasive material. It gives a smooth, linear texture to the surface, resulting in a contemporary and elegant appearance. 3. Polished Finish: This finish is achieved by polishing the steel sheet with abrasive materials until it becomes smooth and reflective. It provides a high-gloss, mirror-like appearance, making it suitable for applications that require a sophisticated and luxurious look. 4. Embossed Finish: In this finish, the steel sheet is pressed with embossing tools to create textured patterns or designs on the surface. This gives the sheet a unique and decorative appearance, making it ideal for architectural applications where visual interest is desired. 5. Patterned Finish: This finish involves applying a pattern or texture onto the steel sheet using various techniques like etching, laser cutting, or perforating. It creates a visually appealing surface with intricate designs, making it suitable for both functional and decorative purposes. 6. Powder Coated Finish: In this finish, a layer of dry powder paint is electrostatically applied to the steel sheet and then cured under heat. It provides a durable and vibrant finish, available in a wide range of colors and textures. This finish is highly resistant to chipping, scratching, and fading, making it ideal for exterior architectural applications. 7. Galvanized Finish: This finish is achieved by applying a layer of zinc coating onto the steel sheet through a process called galvanization. It provides excellent corrosion resistance, making it suitable for outdoor architectural applications where the steel sheet is exposed to harsh environments. Overall, the choice of steel sheet finish depends on the desired aesthetics, durability, and environmental conditions of the architectural application.

- Q: How do you store steel sheets to prevent damage?

- To prevent damage while storing steel sheets, it is important to keep them in a dry and well-ventilated area to avoid moisture buildup. Additionally, stacking them horizontally with proper support and using separators such as wooden pallets or rubber mats between each sheet can prevent scratches and dents. Regular inspection for any signs of corrosion or damage is also essential to address any issues promptly.

- Q: Can steel sheets be customized according to specific requirements?

- Indeed, it is possible to customize steel sheets to meet specific requirements. Steel manufacturers possess the capacity to manufacture steel sheets in different sizes, thicknesses, and finishes, catering to the unique needs of customers. The customization options extend to include specific alloy compositions, surface treatments, and mechanical properties. By employing cutting, shearing, bending, and shaping techniques, steel sheets can be tailor-made to fit precise dimensions and shapes, suitable for various applications. Furthermore, manufacturers can also accommodate personalized branding, labeling, and packaging preferences as dictated by the customer. In conclusion, steel sheets offer a remarkable degree of flexibility and can be readily customized to satisfy specific requirements.

- Q: Are steel sheets suitable for harsh weather conditions?

- Yes, steel sheets are highly suitable for harsh weather conditions. Steel is known for its durability, strength, and ability to withstand extreme weather elements such as heavy rain, strong winds, and snow. It is also resistant to corrosion, making it a reliable choice for outdoor applications in harsh climates.

- Q: How do steel sheets perform in extreme weather conditions?

- Steel sheets perform well in extreme weather conditions due to their high strength and durability. They are resistant to corrosion, fire, and can withstand intense winds, heavy rain, and extreme temperatures. Additionally, steel sheets have excellent structural stability, making them suitable for use in various applications, such as roofing, cladding, and construction, even in harsh weather environments.

Send your message to us

FDCORRIGATED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords