Stainless Steel Sheet with Mid Year Sales for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet with Mid Year Sales for Building

Description of Stainless Steel Sheet with Mid Year Sales for Building:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet with Mid Year Sales for Building:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel Sheet with Mid Year Sales for Building:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel Sheet with Mid Year Sales for Building:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet with Mid Year Sales for Building:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel Sheet with Mid Year Sales for Building:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

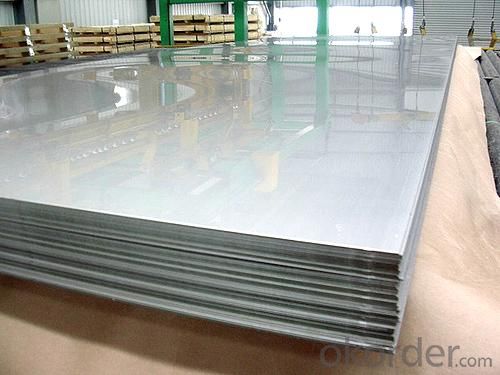

Images of Stainless Steel Sheet with Mid Year Sales for Building:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q: What are the different types of stainless steel sheet finishes for architectural applications?

- There are several different types of stainless steel sheet finishes that are commonly used in architectural applications. These finishes are applied to the surface of the stainless steel sheet to enhance its appearance and provide additional protection against corrosion and wear. 1. No. 1 Finish: This is the most common type of stainless steel sheet finish. It is also known as "hot rolled annealed and pickled" finish. In this finish, the stainless steel sheet is hot rolled, resulting in a dull, rough surface. It is then annealed and pickled to remove any scale or impurities, leaving a clean, uniform surface. 2. No. 2B Finish: This finish is achieved by cold rolling the stainless steel sheet after it has been annealed and pickled. It results in a smooth, reflective surface with a slight grainy texture. No. 2B finish is commonly used for applications that require a high level of corrosion resistance and a polished appearance. 3. No. 4 Finish: Also known as "brushed finish," No. 4 finish is achieved by mechanically polishing the stainless steel sheet with abrasive belts or brushes. It creates a satin-like appearance with fine parallel lines. No. 4 finish is often used for decorative purposes in architectural applications such as wall panels, elevator interiors, and column covers. 4. No. 8 Mirror Finish: This finish is achieved by mechanically polishing the stainless steel sheet to a highly reflective mirror-like surface. It provides a bright, reflective appearance and is commonly used for decorative applications such as wall cladding, signage, and decorative trim. 5. Bead Blasted Finish: In this finish, the stainless steel sheet is blasted with fine glass beads to create a textured, matte surface. Bead blasted finish offers a unique aesthetic and is often used in applications where a non-reflective, tactile surface is desired, such as elevator doors, handrails, and countertops. 6. Patterned Finish: Patterned finishes are achieved by embossing or etching the stainless steel sheet with various patterns or textures. This creates a decorative surface that adds visual interest to architectural applications. Patterned finishes are commonly used for wall panels, ceiling tiles, and decorative screens. These are just a few of the most common stainless steel sheet finishes used in architectural applications. Each finish offers its own unique aesthetic and functional characteristics, allowing architects and designers to choose the most suitable finish for their specific project requirements.

- Q: Can stainless steel sheets be used for automotive exhaust systems?

- Yes, stainless steel sheets can be used for automotive exhaust systems. Stainless steel is a popular choice for exhaust systems due to its high heat resistance, corrosion resistance, and durability. It can withstand the high temperatures and corrosive gases produced by the exhaust, making it a suitable material for this application.

- Q: How do you prevent scratching on stainless steel sheets during handling and installation?

- To prevent scratching on stainless steel sheets during handling and installation, there are several steps you can take: 1. Use protective covering: Apply a protective covering or film on the surface of the stainless steel sheets before handling or installing them. This covering acts as a barrier, preventing scratches and scuff marks during transportation and installation. Ensure that the covering is suitable for stainless steel and does not leave any residue upon removal. 2. Handle with care: Be mindful of how you handle the stainless steel sheets. Avoid dragging or sliding them against rough surfaces or each other, as this can cause scratches. Instead, use proper lifting techniques and handle the sheets with clean, dry hands or gloves to minimize the risk of leaving marks. 3. Use appropriate tools: When working with stainless steel sheets, make sure to use tools that are specifically designed for this purpose. Avoid using tools with rough or abrasive surfaces that could scratch the stainless steel. Opt for tools made from soft materials or with protective coatings to minimize the chances of damaging the surface. 4. Clean work areas: Before installing stainless steel sheets, ensure that the work area is clean and free from any debris or particles that could potentially scratch the surface. Wipe down the area with a clean cloth or soft brush to remove any dirt, dust, or loose materials that could cause scratches during installation. 5. Secure sheets during transportation: If you need to transport stainless steel sheets, ensure that they are properly secured to prevent any movement or shifting that could lead to scratches. Use appropriate packaging materials such as foam inserts, edge protectors, or straps to keep the sheets in place and minimize the risk of damage. By following these preventive measures, you can significantly reduce the risk of scratching stainless steel sheets during handling and installation, ensuring a pristine finish and maintaining the quality of the material.

- Q: Can stainless steel sheets be used in medical applications?

- Yes, stainless steel sheets can be used in medical applications. Stainless steel is commonly used in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is often used for surgical instruments, medical equipment, implants, and other medical devices.

- Q: Are stainless steel sheets suitable for water tanks?

- Yes, stainless steel sheets are suitable for water tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for water storage. It is durable, long-lasting, and can withstand high water pressures. Additionally, stainless steel is hygienic, easy to clean, and does not contaminate the water.

- Q: What are the different types of etched patterns available for stainless steel sheets?

- There are various types of etched patterns available for stainless steel sheets, including geometric designs, floral motifs, abstract patterns, textured surfaces, and custom designs.

- Q: 420 stainless steel, there is no good 304

- Depends on what you used to do, 420 hardness is higher than 304, more suitable for cutting tools and so on; but 304, corrosion resistance is better than 420, if you take into account the problem of rust, 304 better.

- Q: How do you prevent galvanic corrosion when using stainless steel sheets?

- To avoid galvanic corrosion when utilizing stainless steel sheets, there are several precautions you can take: 1. Steer clear of direct contact with dissimilar metals: Galvanic corrosion arises when two different metals make contact in the presence of an electrolyte, such as moisture. To prevent this, ensure that stainless steel sheets do not come into direct contact with dissimilar metals, particularly those with a higher anodic index, such as aluminum or copper. If contact cannot be avoided, utilize insulating materials like plastic or rubber gaskets to separate the metals. 2. Choose compatible fasteners: When securing stainless steel sheets, it is essential to select fasteners crafted from the same or compatible metals. The utilization of dissimilar metals can form galvanic cells, resulting in corrosion. It is recommended to use stainless steel fasteners or those composed of materials with similar corrosion resistance, such as galvanized steel. 3. Apply protective coatings: The application of protective coatings on stainless steel sheets can serve as an additional barrier against galvanic corrosion. Consider utilizing paint, epoxy, or other suitable coatings that are compatible with stainless steel. These coatings act as sacrificial layers, preventing direct contact between the stainless steel and the surrounding environment. 4. Insulate electrical connections: If stainless steel sheets are involved in electrical systems, ensure adequate insulation of electrical connections. This prevents the flow of electrical current between dissimilar metals, reducing the risk of galvanic corrosion. Insulating materials like plastic or rubber sleeves can be employed to separate the metals and impede the formation of galvanic cells. 5. Regulate environmental factors: Galvanic corrosion is often accelerated in the presence of moisture, saltwater, or acidic environments. Controlling these factors can help prevent corrosion on stainless steel sheets. Routinely clean and dry the sheets, particularly in areas where moisture accumulates. Avoid exposing the sheets to saltwater or corrosive chemicals, and maintain proper ventilation to minimize humidity levels. By implementing these preventive measures, you can significantly diminish the likelihood of galvanic corrosion when using stainless steel sheets. However, it is crucial to regularly inspect the sheets for any indications of corrosion and promptly address them to uphold their integrity and longevity.

- Q: Can stainless steel sheets be cut or shaped?

- Yes, stainless steel sheets can be cut or shaped to meet specific requirements. Stainless steel is a versatile material that can be easily manipulated using different cutting and shaping techniques. Cutting stainless steel sheets can be done using methods such as shearing, laser cutting, or waterjet cutting. Shaping stainless steel sheets can be achieved through processes like bending, rolling, or stamping. These techniques allow for the creation of various forms and designs, making stainless steel sheets a popular choice in industries such as construction, automotive, and manufacturing.

- Q: Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Aluminum sheet material is light, easy to shape, good coloring;

Send your message to us

Stainless Steel Sheet with Mid Year Sales for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords