Stainless Steel Sheet With Best Price In 200 Series Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

We are one of the biggest manufacturesfor producing stainless steel sheet.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

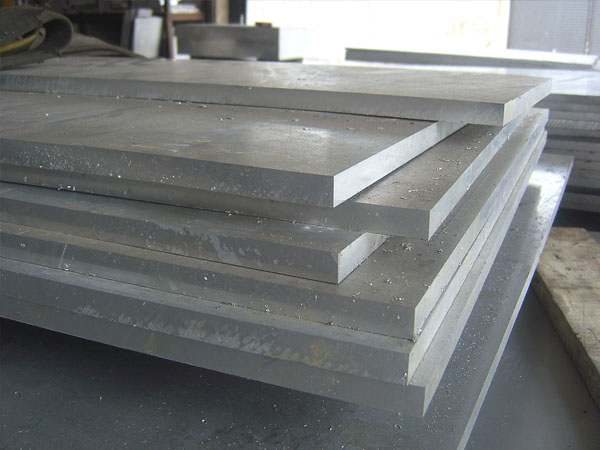

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What are the pricing options for stainless steel sheets?

- The pricing options for stainless steel sheets can vary depending on factors such as the size, thickness, grade, and finish of the sheets. Generally, stainless steel sheets can range in price from around $30 to $300 per sheet.

- Q: Can stainless steel sheets be bent?

- Yes, stainless steel sheets can be bent. However, the degree of bendability depends on the thickness and grade of the stainless steel.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q: Can stainless steel sheets be used for fermentation tanks?

- Yes, stainless steel sheets can be used for fermentation tanks. Stainless steel is a popular choice for fermentation tanks due to its resistance to corrosion, durability, and ease of cleaning. It provides a hygienic environment for fermentation processes and helps maintain the desired temperature and conditions for fermentation.

- Q: How about stainless steel grades?

- 304 - that is, 18/8 stainless steel. GB is 0Cr18Ni9. 309 - better temperature resistance than 304. 316 - after 304, second of the most widely used steel grades are used mainly in the food, pharmaceutical and pharmaceutical industries, and molybdenum is added to obtain a special corrosion resistant structure. Because of its better resistance to chloride corrosion than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel usually meets this application level. [

- Q: Are stainless steel sheets available in different finishes?

- Yes, stainless steel sheets are available in different finishes.

- Q: Can stainless steel sheets be used for wastewater treatment?

- Yes, stainless steel sheets can be used for wastewater treatment. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and corrosive elements often found in wastewater treatment processes. Additionally, its smooth surface makes it easy to clean and maintain, ensuring long-term durability and effectiveness in treating wastewater.

- Q: Can stainless steel sheets be used for storage tanks?

- Yes, stainless steel sheets can indeed be used for storage tanks. Stainless steel is known for its high corrosion resistance, making it an ideal material for storing various substances, including chemicals, liquids, and gases. It is highly durable, which ensures a longer lifespan for the storage tank and reduces the risk of leaks or contamination. Stainless steel tanks are also easy to clean and maintain, making them suitable for industries such as food and beverage, pharmaceuticals, and wastewater treatment. Additionally, stainless steel is non-reactive, meaning it does not interact with the stored substances, ensuring the integrity and quality of the materials being stored. Overall, stainless steel sheets are a reliable and versatile choice for storage tank applications.

- Q: Are stainless steel sheets good for chemical processing?

- Stainless steel sheets are renowned for their exceptional performance in chemical processing. Their remarkable resistance to corrosion and chemical damage has made them highly sought-after across various industries, particularly in chemical processing. The abundant presence of chromium and nickel in stainless steel imparts it with an extraordinary ability to withstand chemical reactions, even when exposed to harsh chemicals and acids. Furthermore, stainless steel sheets offer hassle-free cleaning, maintenance, and sterilization, which are crucial factors in chemical processing environments where cleanliness and hygiene are of utmost importance. The durability and strength of stainless steel sheets also guarantee their longevity and capacity to endure extreme temperatures and pressures, rendering them suitable for a wide array of chemical processing applications. All in all, stainless steel sheets emerge as a dependable and efficient choice for chemical processing due to their corrosion resistance, ease of maintenance, and enduring nature.

Send your message to us

Stainless Steel Sheet With Best Price In 200 Series Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords