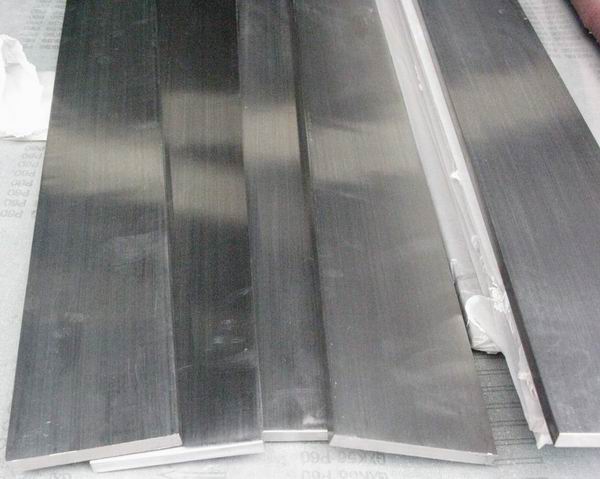

Stainless Steel Flat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304 Stainless Steel Flat Details:

| Minimum Order Quantity: | 5 Tons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 1000 Tons Per Month | Payment Terms: | TT or LC |

Product Description:

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1 Ton

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

Size | Thickness (mm) | |||||||||||

Width (mm) | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 25 | 30 |

Theoretical Weight (kg/m) | ||||||||||||

10 | 0.238 | 0.32 | 0.4 | 0.48 | 0.63 | |||||||

15 | 0.36 | 0.48 | 0.59 | 0.71 | 0.95 | 1.19 | ||||||

20 | 0.476 | 0.63 | 0.79 | 0.95 | 1.27 | 1.59 | 1.9 | |||||

25 | 0.585 | 0.79 | 0.99 | 1.19 | 1.59 | 1.98 | 2.38 | |||||

30 | 0.714 | 0.95 | 1.19 | 1.43 | 1.9 | 2.38 | 2.85 | 3.33 | 3.81 | 4.75 | 5.948 | |

40 | 0.952 | 1.27 | 1.59 | 1.9 | 2.54 | 3.17 | 3.81 | 4.44 | 5.08 | 6.34 | 7.93 | 9.52 |

50 | 1.19 | 1.59 | 1.98 | 2.38 | 3.17 | 3.97 | 4.76 | 5.55 | 6.34 | 7.93 | 9.91 | 11.9 |

60 | 1.428 | 1.9 | 2.38 | 2.85 | 3.81 | 4.76 | 5.71 | 6.66 | 7.61 | 9.52 | 11.9 | 14.27 |

70 | 2.22 | 2.78 | 3.33 | 4.44 | 5.55 | 6.66 | 7.77 | 8.88 | 11.1 | 13.88 | 16.65 | |

80 | 3.17 | 3.81 | 5.08 | 6.34 | 7.61 | 8.88 | 10.15 | 12.69 | 15.86 | 19.03 | ||

90 | 3.57 | 4.28 | 5.71 | 7.14 | 8.56 | 9.99 | 11.42 | 14.27 | 17.84 | 21.41 | ||

100 | 3.97 | 4.76 | 6.34 | 7.93 | 9.52 | 11.1 | 12.69 | 15.86 | 19.82 | 23.79 | ||

110 | 5.23 | 6.98 | 8.72 | 10.47 | 12.21 | 13.96 | 17.45 | 21.81 | 26.17 | |||

120 | 5.71 | 7.61 | 9.52 | 11.42 | 13.32 | 15.23 | 19.03 | 23.79 | 28.55 | |||

130 | 6.19 | 8.25 | 10.31 | 12.37 | 14.43 | 16.49 | 20.62 | 25.77 | 30.93 | |||

140 | 6.66 | 8.88 | 11.1 | 13.32 | 15.54 | 17.76 | 22.2 | 27.76 | 33.31 | |||

150 | 7.14 | 9.52 | 11.9 | 14.27 | 16.65 | 19.03 | 23.79 | 29.74 | 35.69 | |||

160 | 7.61 | 12.69 | 15.23 | 17.76 | 20.3 | 25.38 | 31.72 | 38.06 | ||||

170 | 13.48 | 16.18 | 18.87 | 21.57 | 26.96 | 33.7 | 40.44 | |||||

180 | 14.27 | 17.13 | 19.98 | 22.84 | 28.55 | 35.69 | 42.82 | |||||

- Q: Can stainless steel sheets be used for brewery tanks?

- Brewery tanks can indeed utilize stainless steel sheets. In the brewing industry, stainless steel is widely employed due to its exceptional resistance to corrosion, strength, and hygienic characteristics. It is a non-reactive material, meaning it does not interact with the beer or modify its flavor, consequently ensuring the purity and quality of the final product. By shaping and welding stainless steel sheets, tanks of various sizes and shapes can be created, making them suitable for a broad range of brewing applications. Moreover, stainless steel is effortless to clean, maintain, and sanitize, which is crucial for preserving the cleanliness and sterility of brewery tanks. In summary, stainless steel sheets are an ideal choice for brewery tanks due to their durability, chemical resistance, and hygienic properties.

- Q: What does "80 wire" stainless steel plate mean? How much more expensive than the average stainless steel plate?

- Stainless steel terminology, the general thickness of C to calculate the negative difference, the 1 C is 0.01MM, so 80C is 0.8MM. 0.8MM thick stainless steel with different thickness, different prices, generally about Yuegui thin.

- Q: Can stainless steel sheets be used for fermentation tanks?

- Yes, stainless steel sheets can be used for fermentation tanks. Stainless steel is a preferred material for fermentation tanks due to its durability, corrosion resistance, and ability to maintain the desired temperature. It is non-reactive, which means it does not interact with the fermenting substances, ensuring the purity and quality of the product. Stainless steel is also easy to clean and sanitize, which is crucial for maintaining hygienic conditions during the fermentation process. Additionally, stainless steel sheets can be fabricated into various shapes and sizes to meet specific fermentation tank requirements. Overall, stainless steel sheets are a reliable and popular choice for fermentation tanks in various industries, including brewing, winemaking, and food processing.

- Q: What is the cost of stainless steel sheets?

- The cost of stainless steel sheets can vary depending on several factors such as the thickness, size, and grade of stainless steel being used. Generally, stainless steel sheets are priced per square foot or per square meter. The price range can also depend on the supplier, location, and market conditions. Additionally, any additional processing or finishing required, such as polishing or cutting, can also affect the cost. It is recommended to contact a local supplier or distributor to get accurate and up-to-date pricing information for stainless steel sheets.

- Q: Can stainless steel sheets be used for countertops?

- Certainly! Countertops can indeed be made using stainless steel sheets. Stainless steel is a material known for its durability and versatility, as it possesses resistance against stains, heat, and bacteria. Consequently, it proves to be an exceptional option for kitchen countertops. Moreover, stainless steel countertops are effortless to clean and maintain, all while presenting a sleek and contemporary look. While commonly found in commercial kitchens, these countertops are steadily gaining popularity in residential settings, owing to their durable nature and hygienic qualities.

- Q: What's the difference between stainless steel 302 and 304?

- 302 stainless steel and 304 stainless steel are suitable for food processing, storage and transportation. It has good processability and weldability.

- Q: Are stainless steel sheets suitable for fire-rated applications?

- Yes, stainless steel sheets are suitable for fire-rated applications. Stainless steel has excellent fire resistance properties, including high melting point and low thermal conductivity, which make it highly resistant to fire and heat. It does not contribute to the spread of flames and is often used in fire-rated doors, walls, and other applications where fire protection is required.

- Q: What is the thickness tolerance for stainless steel sheets?

- The thickness tolerance for stainless steel sheets can vary depending on the specific grade and manufacturing process. However, in general, the typical thickness tolerance for stainless steel sheets is around +/- 0.005 inches or +/- 0.13 millimeters.

- Q: How can stainless steel sheets be cleaned and maintained?

- Stainless steel sheets are highly durable and resistant to corrosion, making them a popular choice for various applications. To maintain the appearance and functionality of stainless steel sheets, regular cleaning and proper maintenance are essential. Here are some steps to clean and maintain stainless steel sheets: 1. Start by removing any loose dirt or debris from the surface using a soft cloth or a brush. This step helps prevent scratching during the cleaning process. 2. Prepare a cleaning solution by mixing warm water with a mild detergent or dish soap. Avoid using abrasive cleaners or products containing chlorine, bleach, or ammonia, as they can damage the stainless steel surface. 3. Dip a soft cloth or sponge in the cleaning solution and gently scrub the stainless steel sheet in the direction of the grain. Avoid using excessive pressure to prevent scratching. 4. Rinse the sheet thoroughly with clean water to remove any residue from the cleaning solution. Ensure all soap or detergent is completely washed away. 5. Dry the stainless steel sheet using a soft, lint-free cloth. It is important to dry it thoroughly to prevent water spots or streaks from forming. 6. For stubborn stains or fingerprints, use a stainless steel cleaner or specialized stainless steel wipes. Follow the manufacturer's instructions on the product for best results. These cleaners can help restore the shine and remove any tough stains or marks. 7. To prevent scratches, avoid using abrasive materials such as steel wool or rough brushes when cleaning stainless steel sheets. Instead, use soft cloths or non-abrasive sponges. 8. Regularly inspect the stainless steel sheets for any signs of corrosion or damage. If any rust spots or pitting are noticed, use a stainless steel cleaner or passivation solution to restore the surface. Consult with a professional if the damage is extensive. 9. To maintain the appearance of the stainless steel sheet, it is recommended to wipe the surface regularly with a soft cloth or microfiber towel to remove dust, fingerprints, or other marks. By following these cleaning and maintenance steps, stainless steel sheets can retain their original shine, resist corrosion, and remain in excellent condition for an extended period.

- Q: Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

Send your message to us

Stainless Steel Flat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords